Grinding and polishing device and grinding and polishing machine

A grinding and polishing machine, grinding and polishing technology, applied in the direction of grinding drive device, grinding frame, grinding machine tool parts, etc., can solve the problems of low grinding and polishing efficiency, low processing efficiency, poor grinding and polishing effect, etc., to achieve The effect of improving grinding and polishing efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

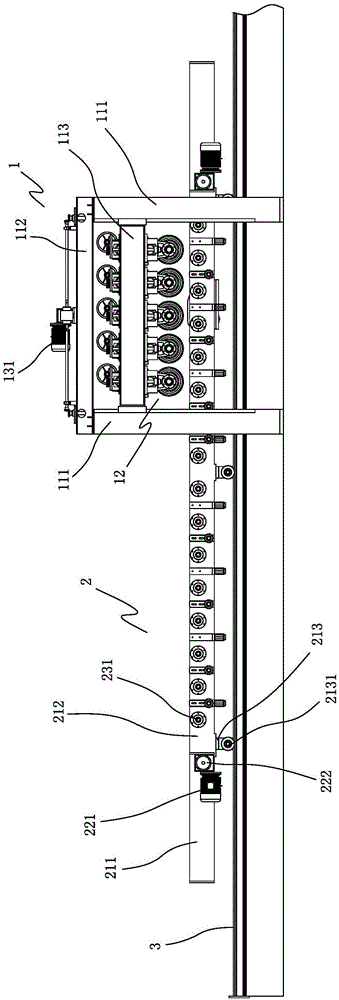

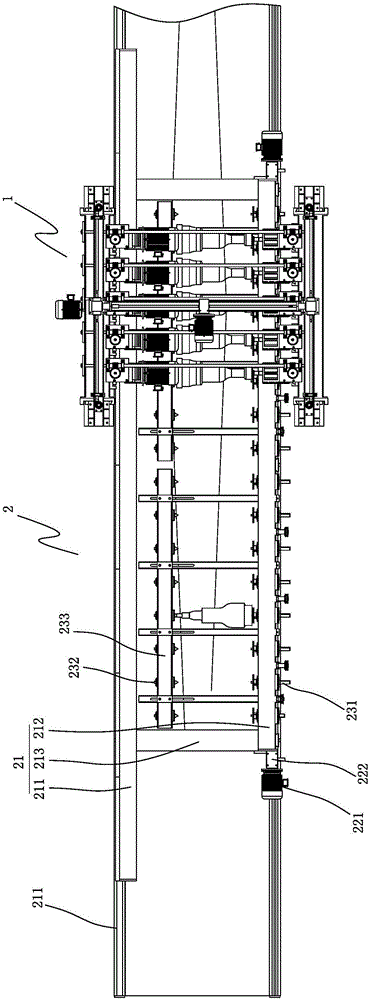

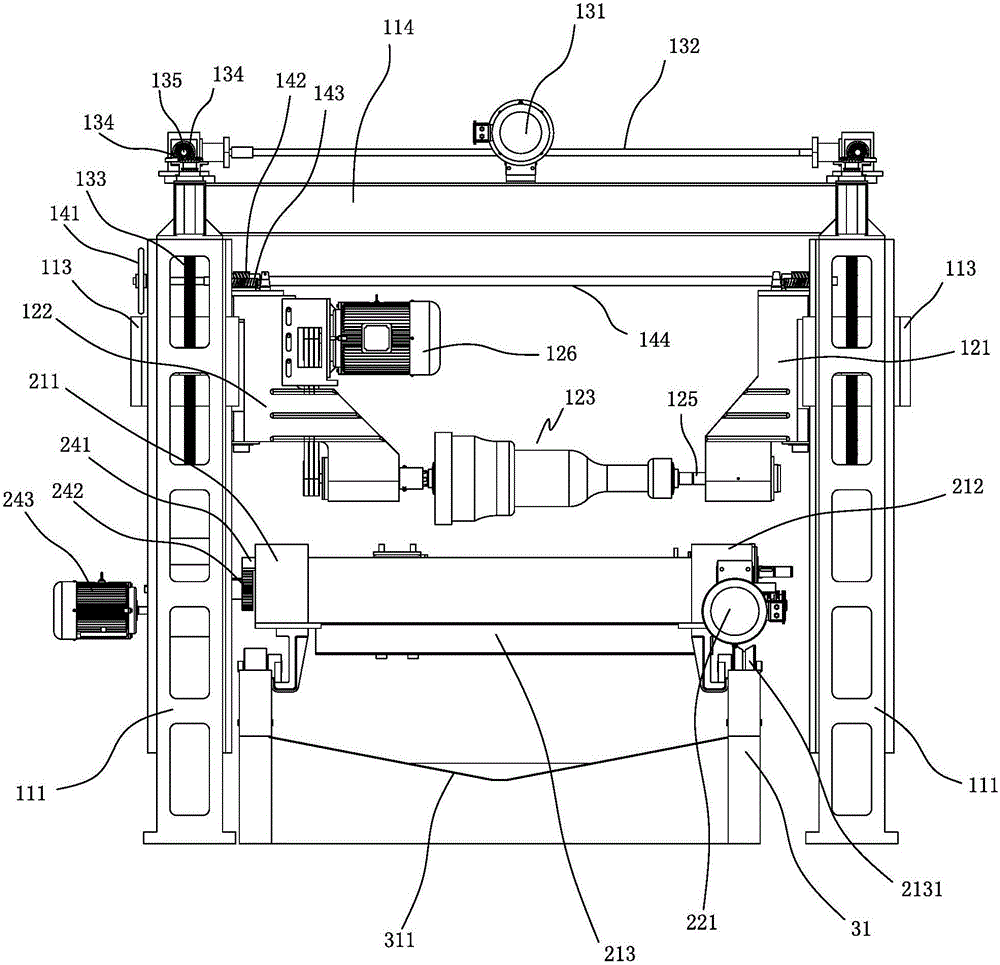

[0030] refer to Figure 1 to Figure 7 As shown, a grinding and polishing machine is used for grinding and polishing the outer peripheral surface of cylindrical stone 4 in batches. Specifically, the cylindrical stone 4 is a stone railing. The grinding and polishing machine includes a grinding and polishing unit 1 and a workpiece clamping device 2; grinding and polishing The unit 1 includes a frame, multiple grinding and polishing devices 12 and a lifting mechanism; the workpiece clamping device 2 includes a moving frame 21, a lateral moving mechanism, multiple rotating clamping mechanisms and a driving mechanism.

[0031] The frame includes four columns 111, two beams 112, a middle beam 114 and two installation beams 113, and the four columns 111 and the two beams 112 form two parallel and spaced relative gantry frames, that is, the gantry frame includes two columns 111 and is connected to two The beam 112 between the tops of the columns 111 and the middle beam 114 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com