Metallographic specimen grinding and polishing equipment and application method thereof

A metallographic sample and equipment technology, which is applied in the field of metallographic experiments, can solve the problems of inability to further cut and prepare large block samples, and achieve the effects of simple structure, convenient clamping, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

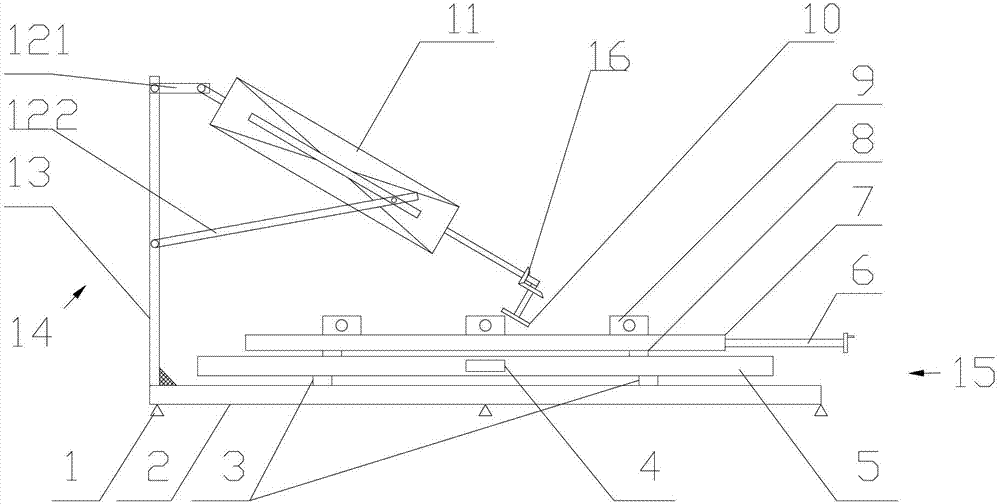

[0023] The present invention will be described in detail below in conjunction with the embodiments shown in the drawings:

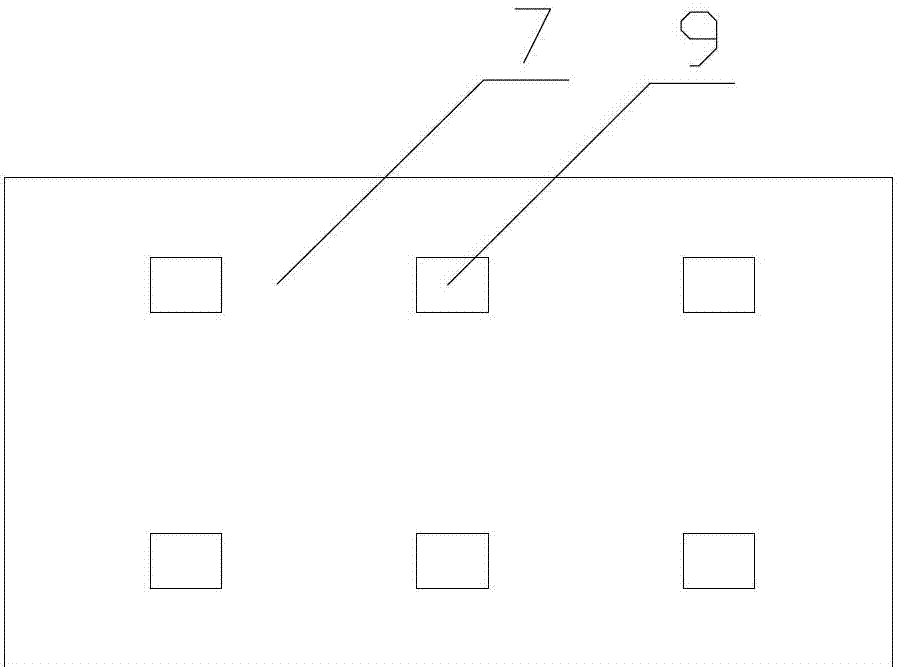

[0024] Such as figure 1 As shown, this metallographic sample grinding and polishing equipment is used for grinding large block metallographic samples, generally refers to metallographic samples with a length and width of 150mm, which includes a fixed base plate 2, a positioning mechanism 15, a motor 11, and polishing Grinding head 10, support frame 14.

[0025] The length direction of the upper end surface of the fixed bottom plate 2 is the longitudinal direction, and the width direction is the transverse direction. The balance support 1 for making the upper end surface parallel to the horizontal plane is arranged below it. The balance support 1 is made of ordinary carbon steel, and its surface roughness Not less than 16um, and the flatness is 0.01~0.03um, so that the levelness of the metallographic sample can be guaranteed. In this embodiment, the flatness i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com