Multi-axis laser-abrasive water jet precision polishing synchronous machining method

An abrasive water jet and synchronous processing technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as uneven laser reflection, low efficiency of water jet polishing, and affecting the beam quality of the workpiece surface, so as to improve the surface quality. Quality, increase grinding and polishing efficiency, increase surface hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

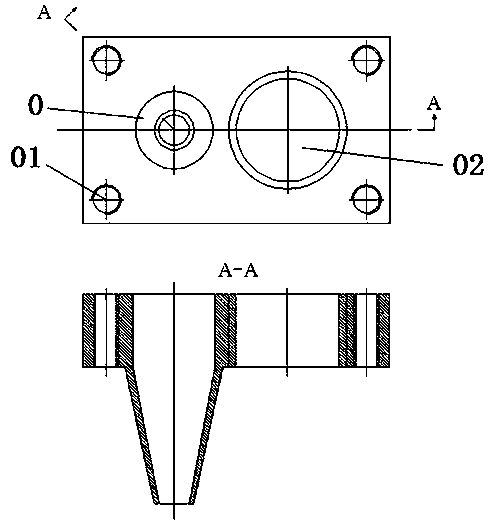

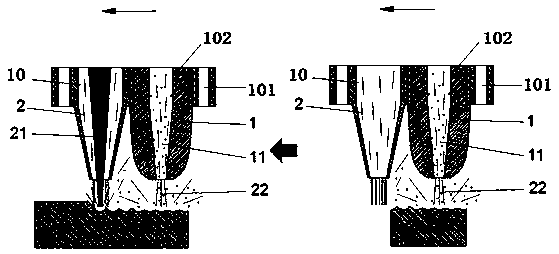

[0026] Such as figure 1 As shown, this specific embodiment provides a multi-axis laser processing technology and an abrasive water jet precision polishing composite processing technology, and its use includes the following steps:

[0027] S1, processing head assembly;

[0028] S2, setting the processing trajectory compensation;

[0029] S3. Implement laser-abrasive water jet synchronous processing.

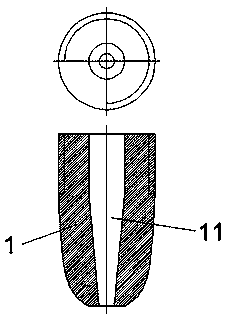

[0030] Install the gas nozzle 0 of the laser processing head and the abrasive water jet processing head 1 on the Z axis. The length of the gas nozzle 0 is 100mm, the diameter of the top is 10mm, the diameter of the bottom is 2mm, the thickness is 1mm, the taper is 1:12.5, the material is aluminum alloy, the spot of the laser 21 is 0.5mm after focusing, the laser pulse width is about 6ps, and the wavelength is 1064nm. Pulse energy 50μJ, frequency 500KHz. The internal ventilation 10 of the processing head 2 is argon, the internal ventilation is argon, the pressure is 1.2MPa, and...

example 2

[0034] Such as figure 1 As shown, this specific embodiment provides a multi-axis laser processing technology and an abrasive water jet precision polishing composite processing technology, and its use includes the following steps:

[0035] S1, processing head assembly;

[0036] S2, setting the processing trajectory compensation;

[0037] S3. Implement laser-abrasive water jet synchronous processing.

[0038] Install the gas nozzle 0 of the laser processing head and the abrasive water jet processing head 1 on the Z axis. The length of the gas nozzle 0 is 100mm, the diameter of the top is 10mm, the diameter of the bottom is 2mm, the thickness is 1mm, the taper is 1:12.5, the material is aluminum alloy, the spot of laser 21 is 2mm after focusing, the laser pulse width is about 6ps, the wavelength is 1064nm, single pulse Energy 70μJ, frequency 300KHz. The internal ventilation 11 of the processing head is argon gas, the pressure is 2.3MPa, and the water content of the gas is 11....

example 3

[0042] Such as figure 1 As shown, this specific embodiment provides a multi-axis laser processing technology and an abrasive water jet precision polishing composite processing technology, and its use includes the following steps:

[0043] S1, processing head assembly;

[0044] S2, setting the processing track compensation;

[0045] S3. Implement laser-abrasive water jet synchronous processing.

[0046] Install the gas nozzle 0 of the laser processing head and the abrasive water jet processing head 1 on the Z axis. The length of the gas nozzle 0 is 100mm, the diameter of the top is 10mm, the diameter of the bottom is 2mm, the thickness is 1mm, the taper is 1:12.5, the material is aluminum alloy, the spot of the laser 21 is 1mm after focusing, the laser pulse width is about 6ps, the wavelength is 1064nm, single pulse Energy 30μJ, frequency 500KHz. The internal ventilation of the processing head is argon, the pressure is 5MPa, and the water content of the gas is 11.36g / kg. Abr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com