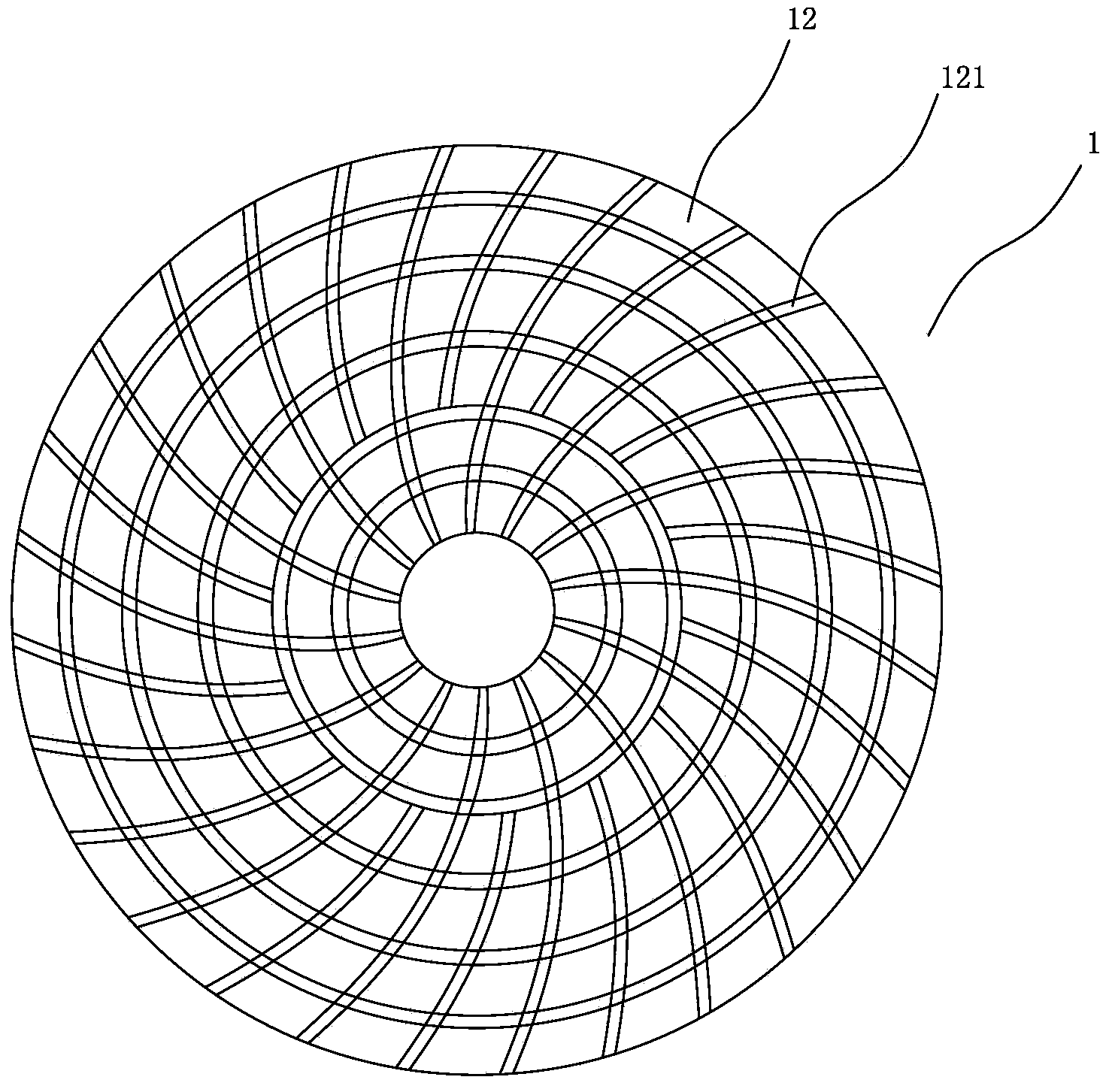

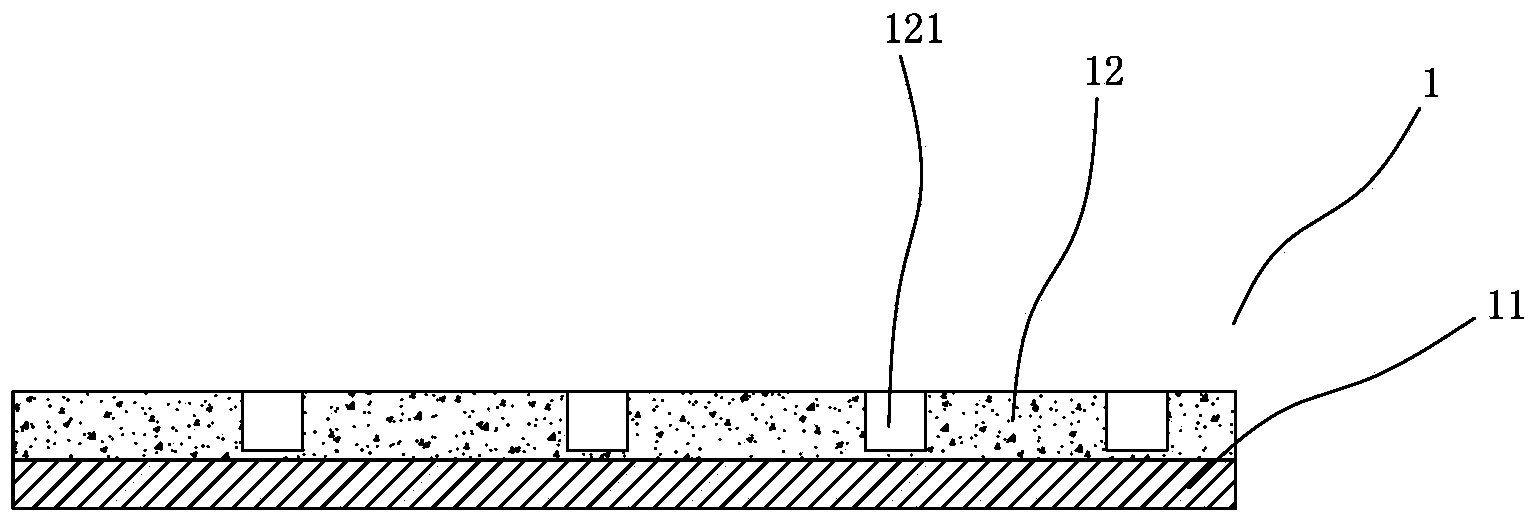

Flexible diamond abrasive disc and manufacturing and polishing technology thereof

A technology for diamond and soft grinding discs, which is applied in the fields of diamond soft grinding discs and their preparation and grinding and polishing processes, can solve the problems of affecting the service life of the soft grinding discs, separating the working layer from the base material, and increasing the processing cost, so as to shorten the processing time and improve the Grinding and polishing efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: The working layer includes the following components by weight: 35 parts of phenolic resin powder, 12 parts of melamine powder, 13 parts of copper powder, 10 parts of diamond, 6 parts of aluminum oxide, 4 parts of tin oxide, 5 parts of tungsten carbide, 2 parts of zinc stearate and 5 parts of vegetable fiber.

Embodiment 2

[0024] Embodiment two: the working layer includes the following components by weight: 38 parts of phenolic resin powder, 8 parts of melamine powder, 15 parts of copper powder, 8 parts of diamond, 8 parts of aluminum oxide, 3 parts of tin oxide, 4 parts of tungsten carbide, 3 parts of zinc stearate and 4 parts of vegetable fiber.

[0025] As a soft grinding disc for rough machining, the particle size of diamond, aluminum oxide, tin oxide and tungsten carbide is 50-220 mesh.

[0026] As a soft grinding disc for fine processing, the particle size of diamond, aluminum oxide, tin oxide and tungsten carbide is 320-800 mesh.

[0027] As a finishing soft grinding disc, the particle size of diamond, aluminum oxide, tin oxide and tungsten carbide is 1000-3000 mesh.

[0028] As a soft grinding disc for polishing, the particle size of diamond, aluminum oxide, tin oxide and tungsten carbide is greater than 6000 mesh.

[0029] The preparation process of diamond soft abrasive discs include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com