Sucker rod fishing tool

a technology for applied in the field of suckers and fishing rods, can solve the problems of limited types of items, easy slipping of sockets, and high cost in time and manpower, and achieve the effects of resisting rotational slippage of suckers, easy use, and easy backed-off from downhol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

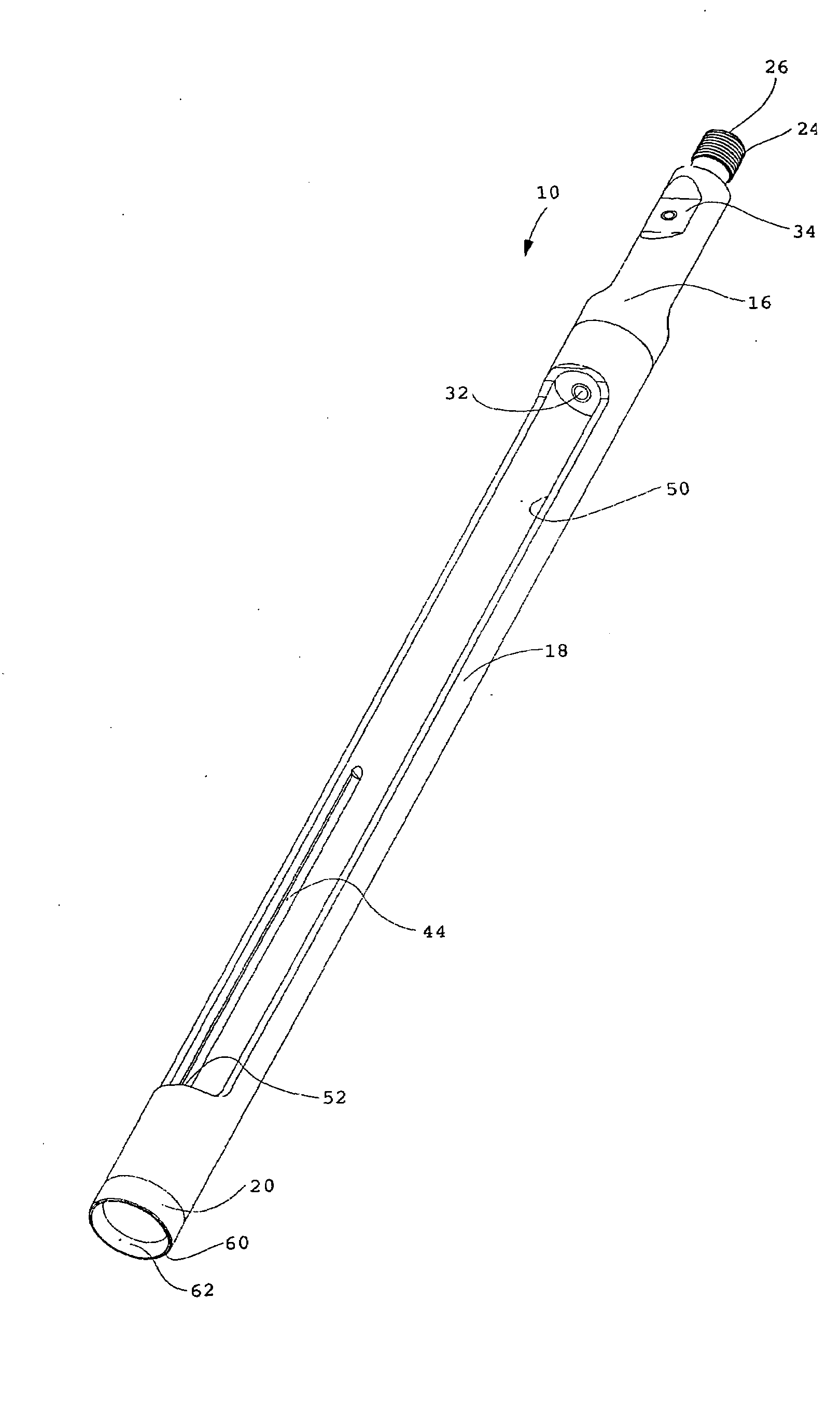

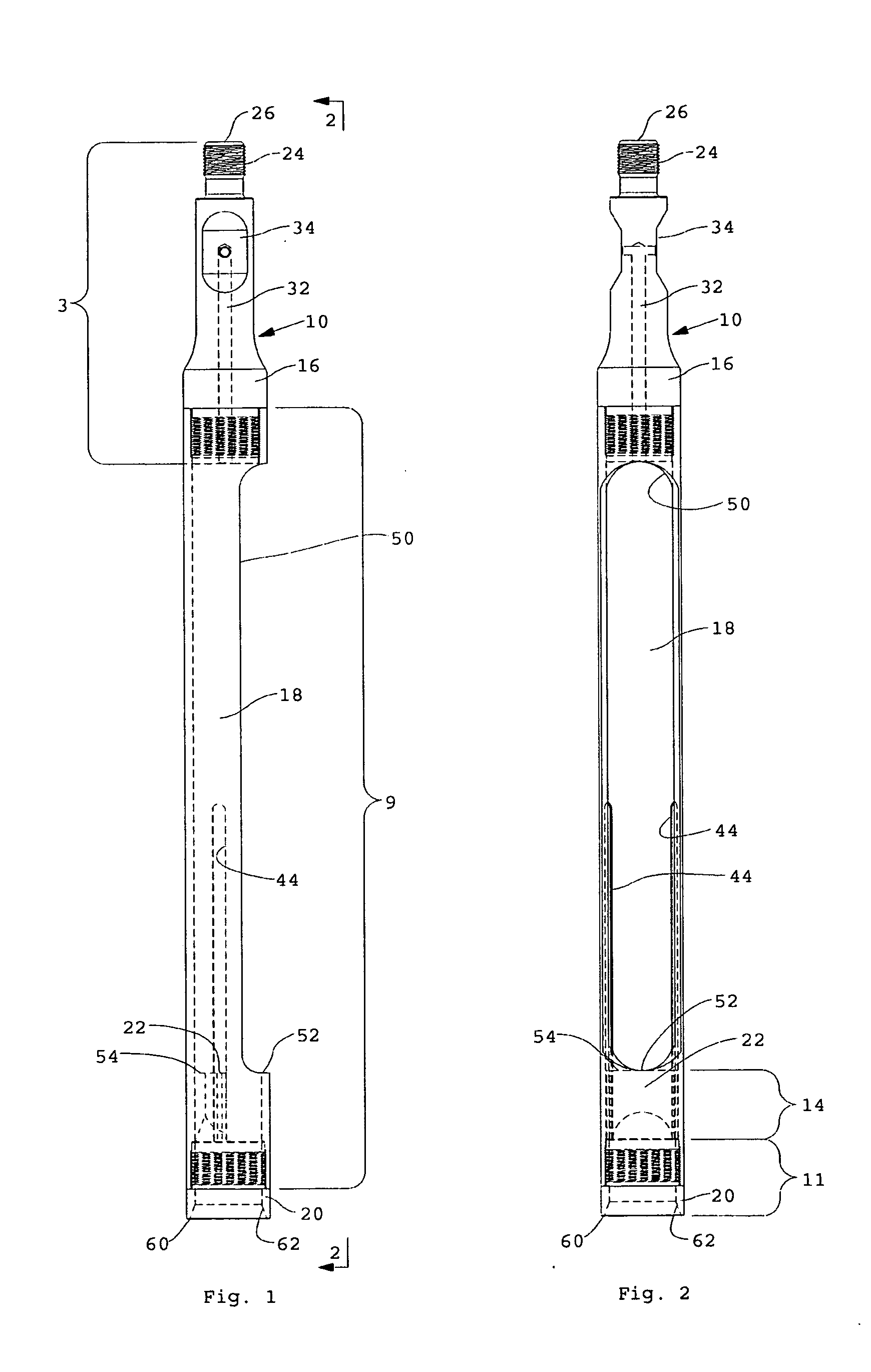

[0069]Referring now to drawings and initially to FIGS. 1, 2, 26 and 32, there is illustrated a fishing tool 10 for fishing sucker rods 12, tubing, pipe, etc. from downhole in a well 14. The body of the tool 10 is constructed of parts or pieces 16, 18 and 20 that are each machined from single pieces of metal stock and provided with threads so that the pieces 16, 18, and 20 can be secured together to form the body of the tool 10. As shown in FIGS. 1 and 2, the body is comprised of a top piece 16 and a barrel piece 18, and normally also is provided with a bottom piece 20. A slip 22, preferable constructed of cast metal, is movably retained within the body, as will be more fully described hereafter. The slip 22 serves to hold the rod 12 within the barrel piece 18 of the tool 10 so that the rod 12 or other item to be fished out of the well 14 can be removed from the well 14 by the tool 10.

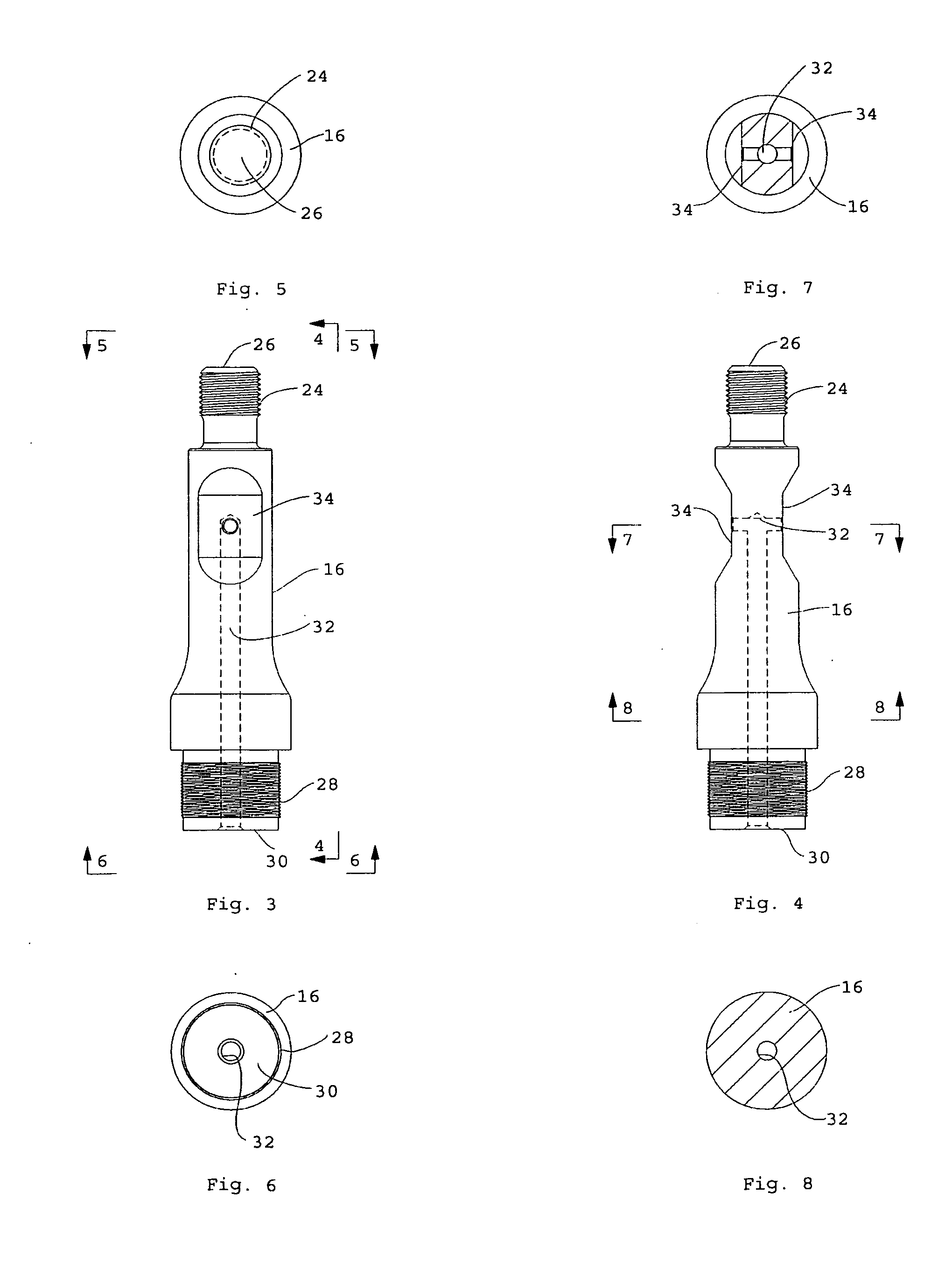

[0070]Referring now to FIGS. 3, 4, 5, 6, 7, and 8, the top piece 16 of the body is constructed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com