Artificial wet land and uses thereof

A constructed wetland and in-situ technology, applied in metallurgical wastewater treatment, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of high concentration of Fe and Mn ions, achieve large treatment capacity, good removal effect, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

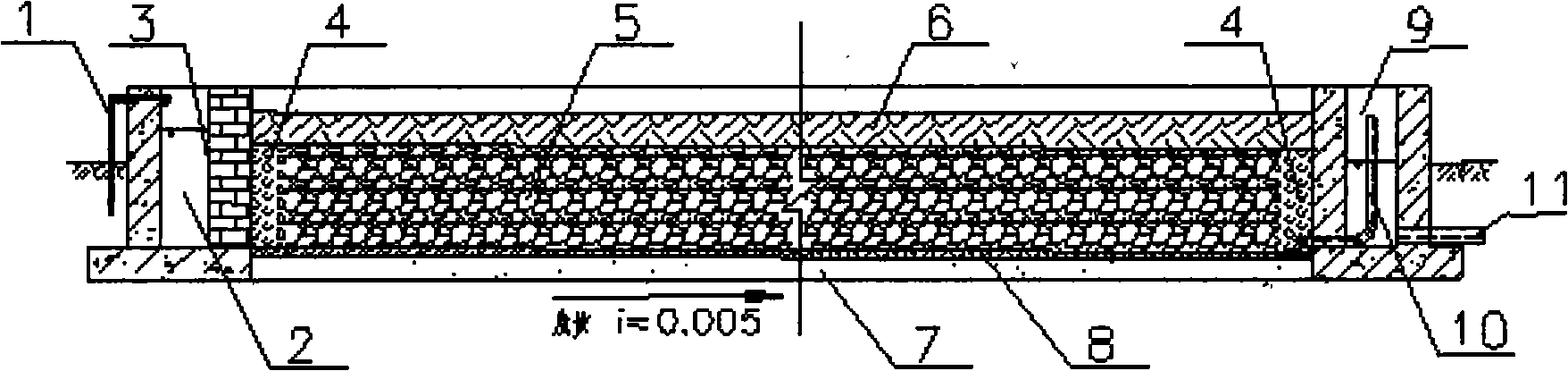

[0060] like figure 1 As shown, the size of the structural horizontal subsurface flow wetland is 15×8m, and the effective area is 93.8m 2 . It is divided into three grids, each grid is 15×2.3m in size, the slope is 5‰, the thickness of the wetland filler layer is 60cm, and the covering soil is 15cm. To prevent leakage, an anti-seepage membrane is laid on the bottom of the wetland.

[0061] In the wetland operation, the water distribution and metering of the three corridors are carried out by the water distribution tank with a triangular metering weir. The water from the water distribution tank passes through the flower wall at the front end of the grid and then flows horizontally into the wetland. A 500mm long pebble (50-100mm in size) water distribution area is set behind the flower wall. After uniform distribution of water, the wetland water passes through the combined packing area composed of 20-30mm gravel, 10-20mm gravel, 5-15mm gravel and 8-16mm manganese sand. The rat...

Embodiment 2

[0069] Other is with embodiment 1, and difference is:

[0070] After uniform water distribution, the wetland inflow passes through the combined packing area composed of 30-40mm gravel, 20-30mm gravel, 10-15mm gravel and 10-20mm manganese sand. The ratio of gravel filler and manganese sand filler with different particle sizes is 60:40 Proportioning, manganese sand filler is arranged in the front section of the packing bed.

Embodiment 3

[0072] Other is with embodiment 1, and difference is:

[0073] After uniform distribution of water, the wetland water passes through the combined packing area composed of 15-25mm gravel, 10-15mm gravel, 5-10mm gravel and 6-8mm manganese sand. The ratio of gravel filler and manganese sand filler with different particle sizes is 80:20 Proportioning, manganese sand filler is arranged at the end of the packing bed.

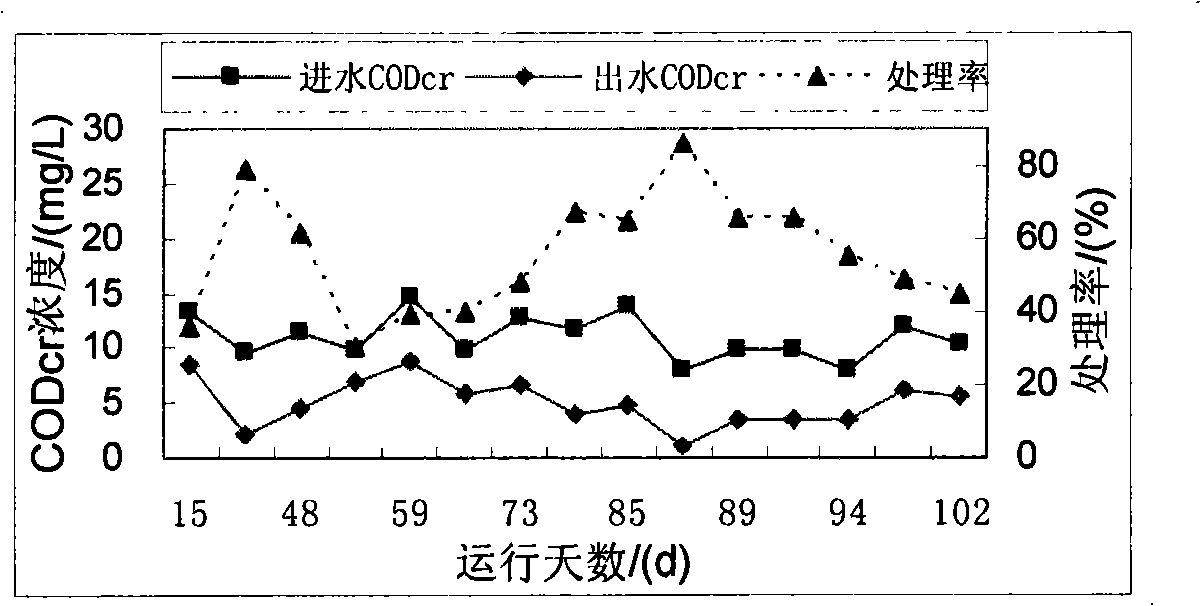

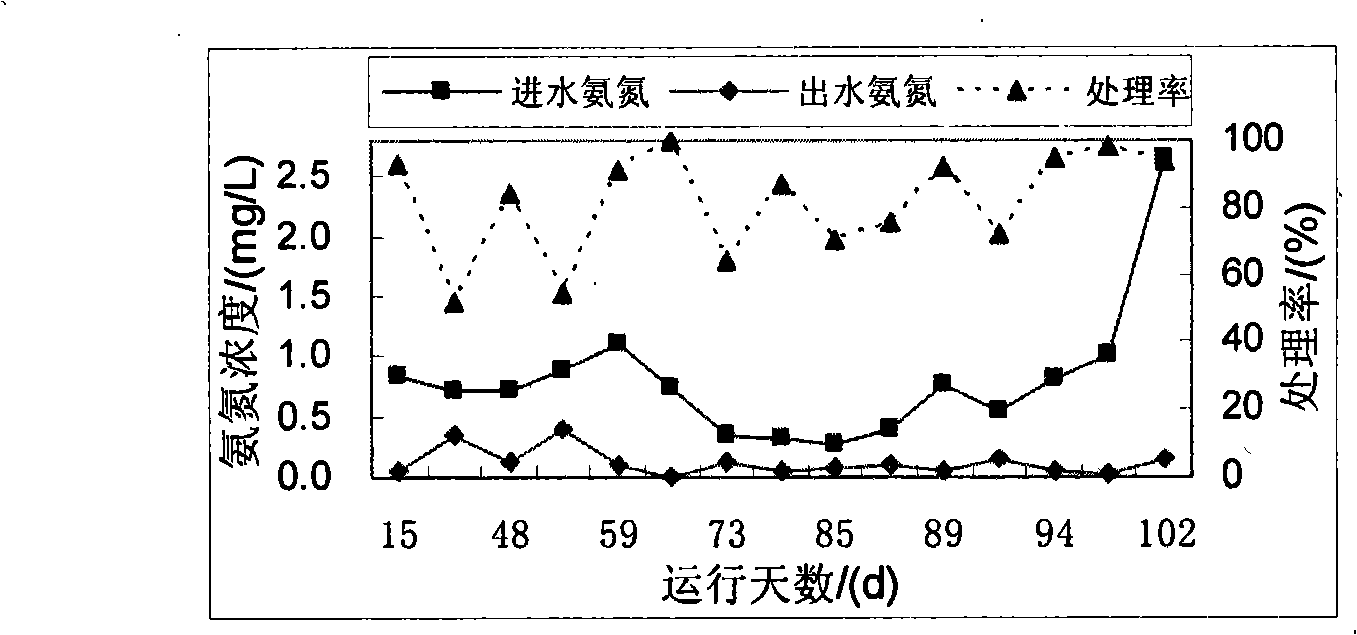

[0074] According to the artificial wetland of the present invention, the construction cost is low, the investment can be greatly saved, the operation and management are convenient, and the treatment cost is low; the present invention uses manganese sand as the new filler of the artificial wetland, which can well solve the problem of Fe, The problem of high concentration of Mn ions; the wastewater treatment effect of the present invention is better, the treatment capacity is larger, and the impact load resistance is stronger, so that most of the indicators of the treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com