Valve controlled residual pressure recovering equipment for impervious desalination system

A desalination system and recovery device technology, applied in reverse osmosis, osmosis/dialysis water/sewage treatment, general water supply conservation, etc., can solve the problems of low efficiency, complicated devices, small processing capacity, etc., and achieve high control accuracy and structure Simple, highly reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

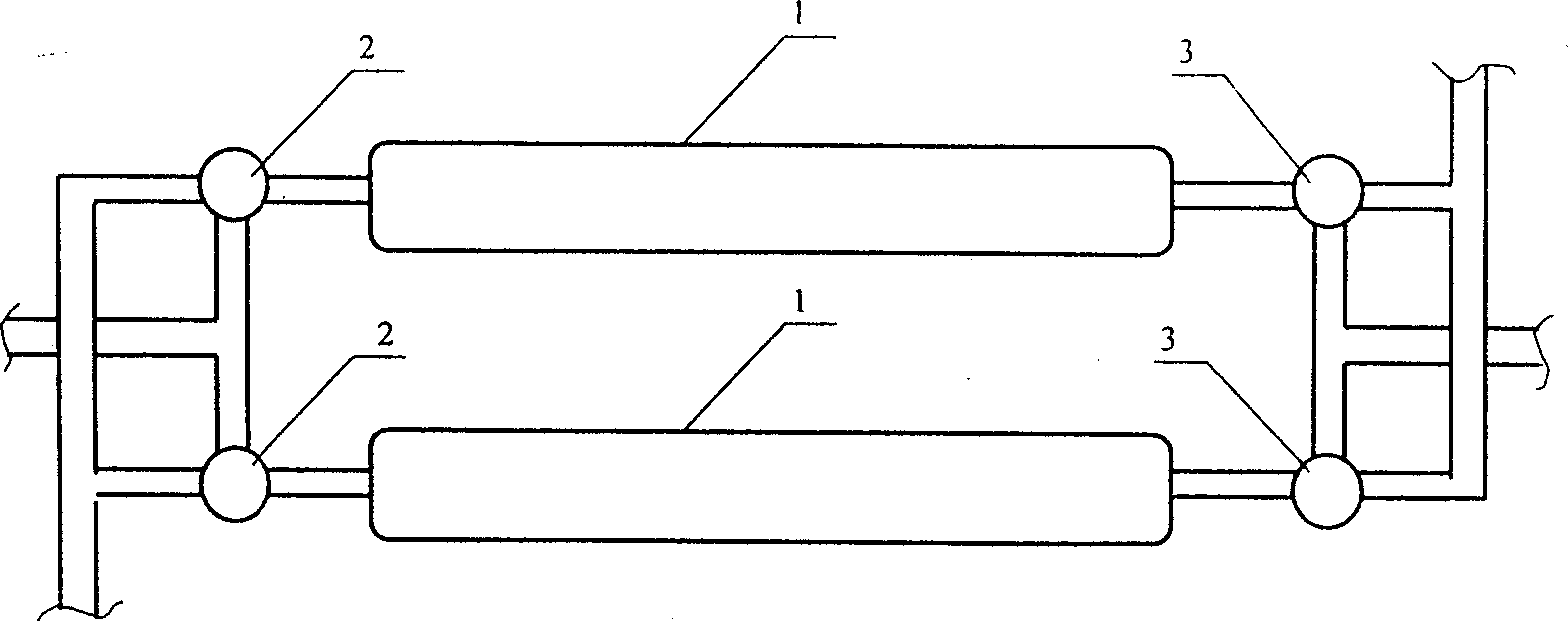

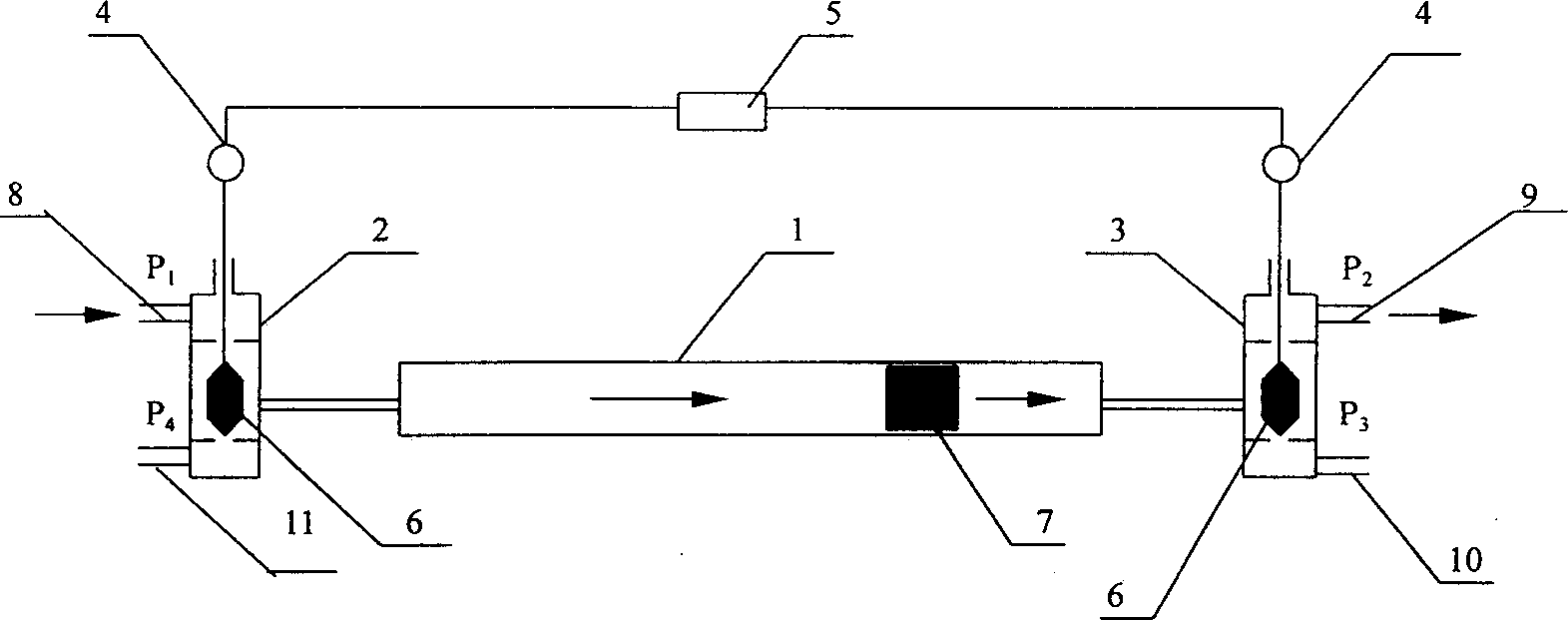

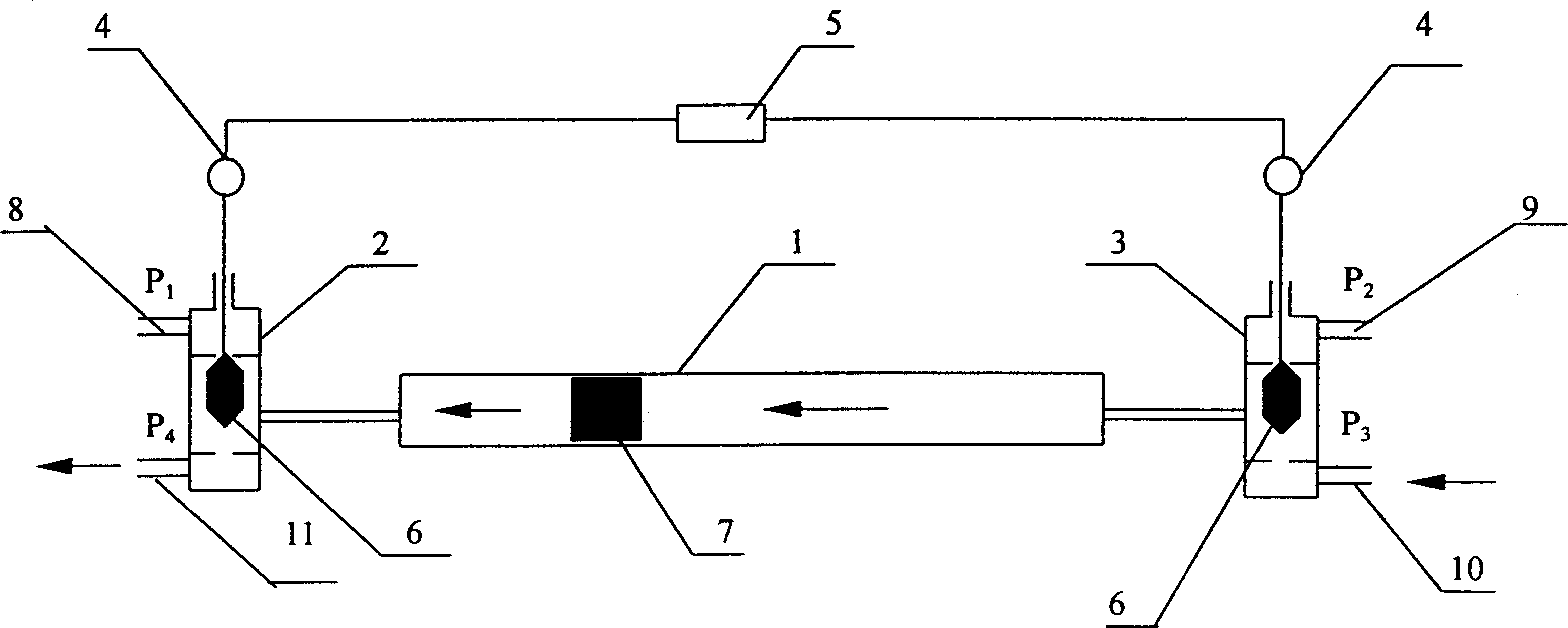

[0017] Principles and implementations are described with reference to the accompanying drawings. figure 1 A schematic diagram of the device. The principle is figure 2 shown. The residual pressure recovery device is composed of a hydraulic cylinder 1, a solenoid valve 2 at the high pressure end and a solenoid valve 3 at the low pressure end. Both solenoid valves are three-way valves. Computer 5 is accurately controlled.

[0018] The pressure of each strand of water in the system has the following relationship: P1>P2>P3>P4

[0019] When the spools 6 of the two valves are downward, the discharge concentrated brine pipe 11 and the raw seawater pipe 10 are cut off simultaneously, while the high-pressure concentrated brine pipe 8 and the pressurized seawater pipe 9 are opened. Because P1>P2, the high-pressure concentrated brine enters the hydraulic cylinder, and the seawater in the cylinder is pressed out, and the pressure of the seawater is increased to P2 at the same time, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com