Coking wastewater deep treatment and reuse process and equipment thereof

A technology for coking wastewater and advanced treatment, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Improve performance, reduce operating costs, and reduce equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

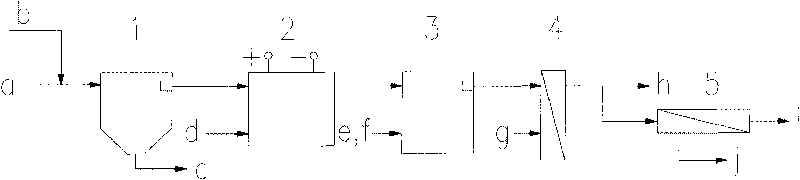

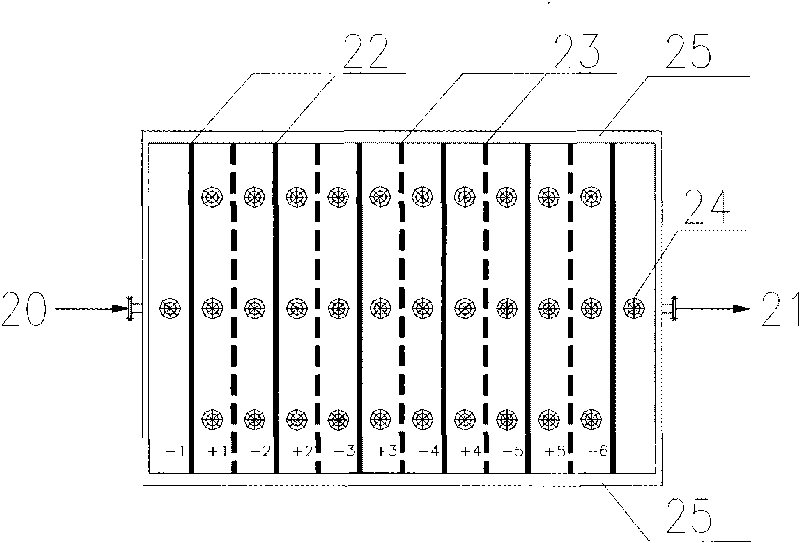

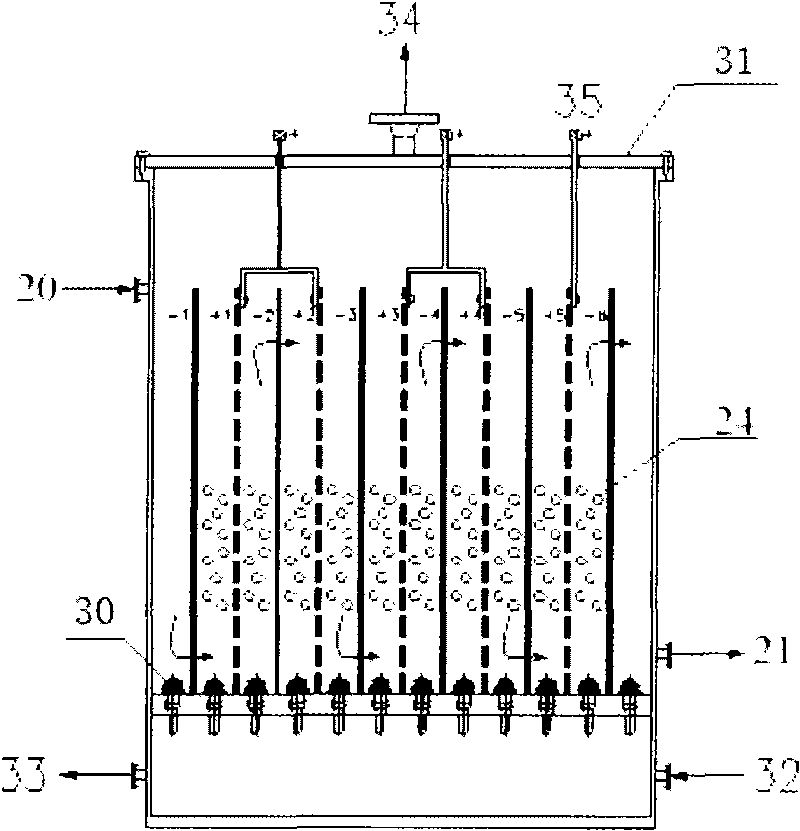

[0027] See figure 1 , a process and equipment for advanced treatment and reuse of coking wastewater, the main steps are: the biochemical treatment water a enters the sedimentation tank 1 after adding a coagulant b, and the sludge c is removed from the sludge hopper after being treated in the sedimentation tank 1 After being discharged, the treated water enters the three-dimensional electrode reactor 2, and the air d required for stirring is provided in the three-dimensional electrode reactor 2. After the electro-oxidation treatment, the effluent enters the biofilter 3, and the biofilter 3 is supplied with the The required air e and the air and water f required for backwashing of the filter, the water treated by the biofilter 3 enters the subsequent ultrafiltration treatment process 4, and the backwashing water and air g are supplied during the ultrafiltration pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com