Reverse osmosis container-type sea water desalination plant and water producing process thereof

A containerized, reverse osmosis technology, applied in osmosis/dialysis water/sewage treatment, seawater treatment, descaling and water softening, etc., can solve the problems of poor environmental protection, high operating cost, inconvenient operation, etc., to overcome the poor environmental protection , The effect of low operating cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

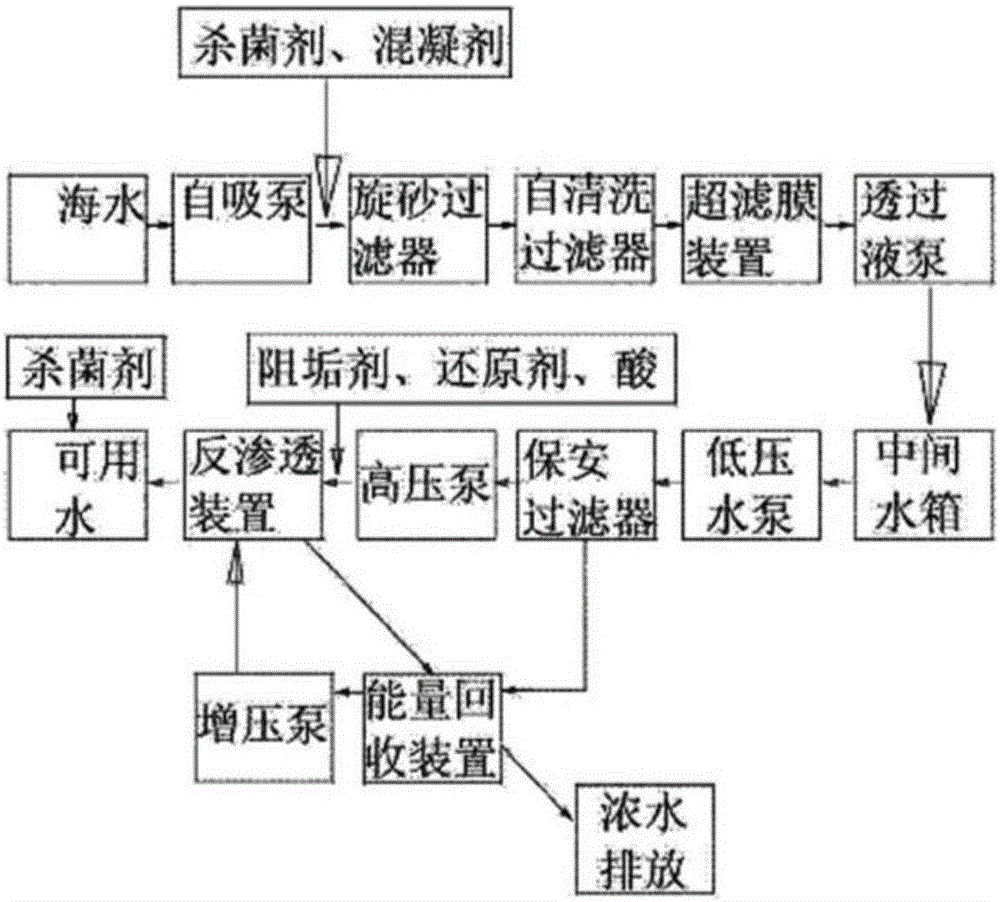

[0061] In order to solve the seawater desalination problem in areas where construction is inconvenient or poor construction conditions and construction sites are limited, a reverse osmosis seawater with a small footprint, compact structure, easy installation, high energy recovery efficiency of concentrated seawater, and an energy recovery device is provided. Desalination integrated process design and equipment.

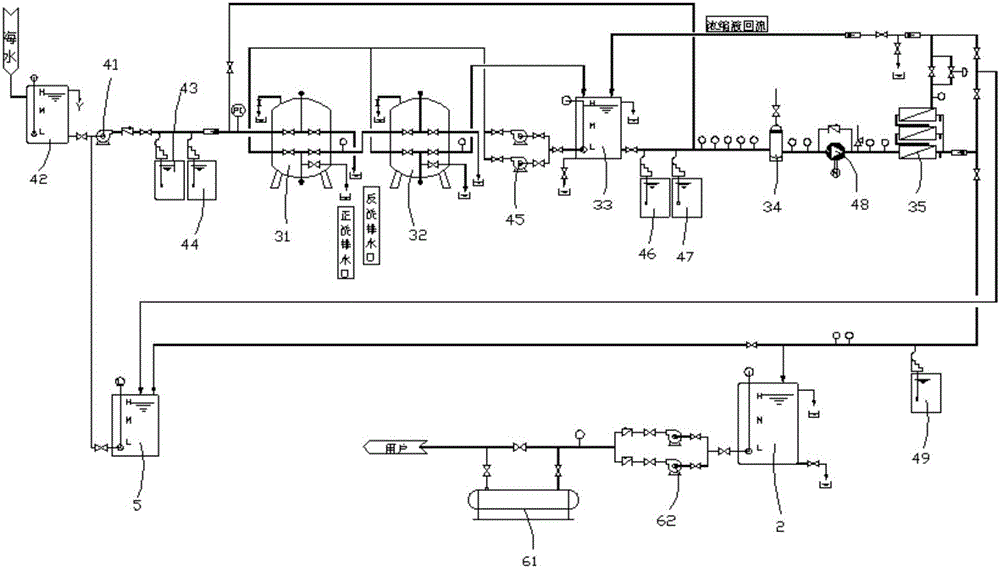

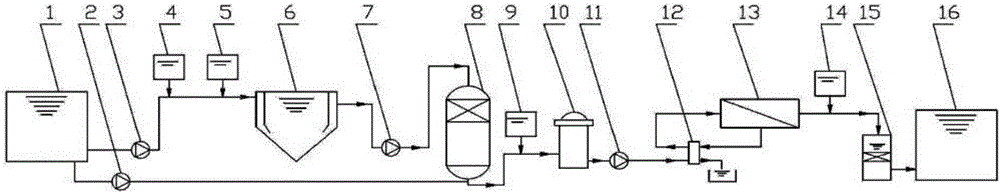

[0062] According to an embodiment of the present invention, such as Figure 4-Figure 6 As shown, a reverse osmosis containerized seawater desalination device and its water production process are provided.

[0063] Aiming at the problems of the existing con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com