Method and apparatus for treatment of concentrated reverse osmosis drainage through coupled forward osmosis and reverse osmosis

A technology of reverse osmosis concentrated drainage and forward osmosis, which is used in osmosis/dialysis water/sewage treatment, chemical instruments and methods, semi-permeable membrane separation, etc. , the effect of simple operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

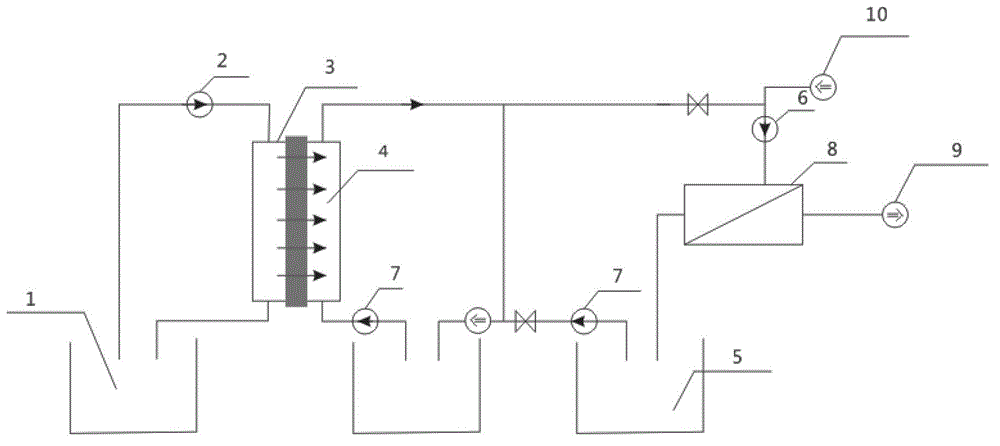

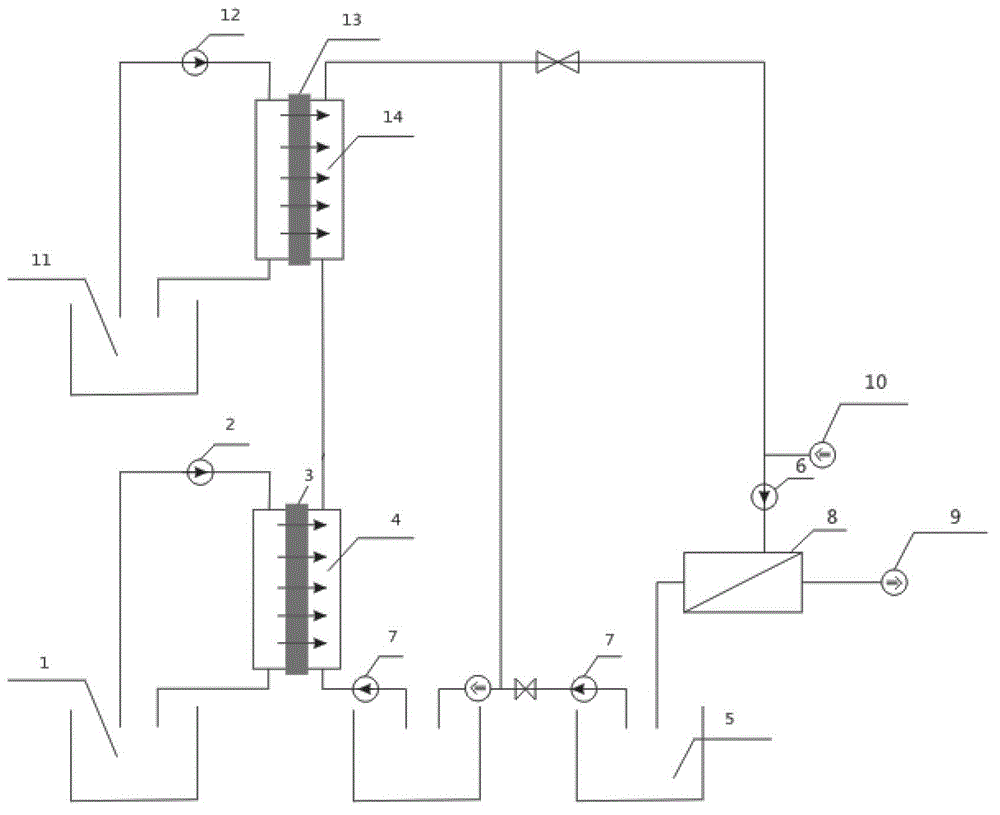

[0044] In this embodiment, the device for treating reverse osmosis concentrated wastewater with forward osmosis coupled with reverse osmosis adopts a primary treatment device (such as figure 1 Shown), the forward osmosis stock solution is concentrated, and the reverse osmosis concentrated wastewater is recycled and reused. Wherein, the primary processing device includes:

[0045] The first forward osmosis stock solution pool 1 for accumulating forward osmosis stock solution;

[0046] A reverse osmosis concentrated drainage storage tank 5 for accumulating reverse osmosis concentrated drainage;

[0047] The first forward osmosis stock solution feed pump 2 is used to transport the forward osmosis stock solution to the first forward osmosis component 3;

[0048] The feed pump 7 is used to transport the first reverse osmosis concentrated drainage 4 as the forward osmosis drive fluid to the forward osmosis module 3;

[0049] Forward osmosis component 3, according to the principle...

Embodiment 2

[0060] According to the method of Example 1, the difference from the above example 1 is that the flow mode is cross flow, and the concentrated product shown is a whey protein solution that is more sensitive to temperature, wherein the whey protein concentration is 3% (mass Concentration), the volume is 100L, operating at room temperature, the flow velocity inside and outside the forward osmosis membrane (forward osmosis stock solution, the flow velocity of the first reverse osmosis concentrated drainage 4) is 1m / s, reverse osmosis concentrated drainage (reverse osmosis seawater desalination Concentrated wastewater) with a volume of 100L. After 2 hours of treatment, the protein concentration was concentrated to 6%. After the reverse osmosis concentrated wastewater was diluted, the mass concentration was reduced to 7% (the concentration of seawater is calculated by sodium chloride content and measured with a salinity meter. ), the diluted drive solution (that is, the diluted reve...

Embodiment 3

[0062] According to the method of Example 1, the difference from the above Example 1 is that the concentration process shown is seawater concentration, the mass concentration of seawater is 3.5%, and the volume is 100L. It is operated at room temperature, and the reverse osmosis concentrated drainage volume is 100L. , the treatment time is 3 hours, the flow velocity inside and outside the forward osmosis membrane (the flow velocity of the forward osmosis stock solution and the first reverse osmosis concentrated drainage 4) is 2m / s, and the seawater concentration is concentrated to 6.3%. After the reverse osmosis concentrated drainage is diluted, the mass concentration is reduced to 7% (the concentration of seawater is calculated by the content of sodium chloride and measured with a salinity meter), and the diluted drive solution is mixed with reverse osmosis raw water 10% (the reverse osmosis raw water here is 10% Sea water) is mixed with a volume ratio of 1:4 as the feed water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com