Wastewater treatment method and wastewater treatment system

A waste water treatment system and treatment method technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, ion exchange water/sewage treatment, etc. Low recycling rate and other issues, to achieve the effect of long continuous operation period, lower organic content and less organic pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

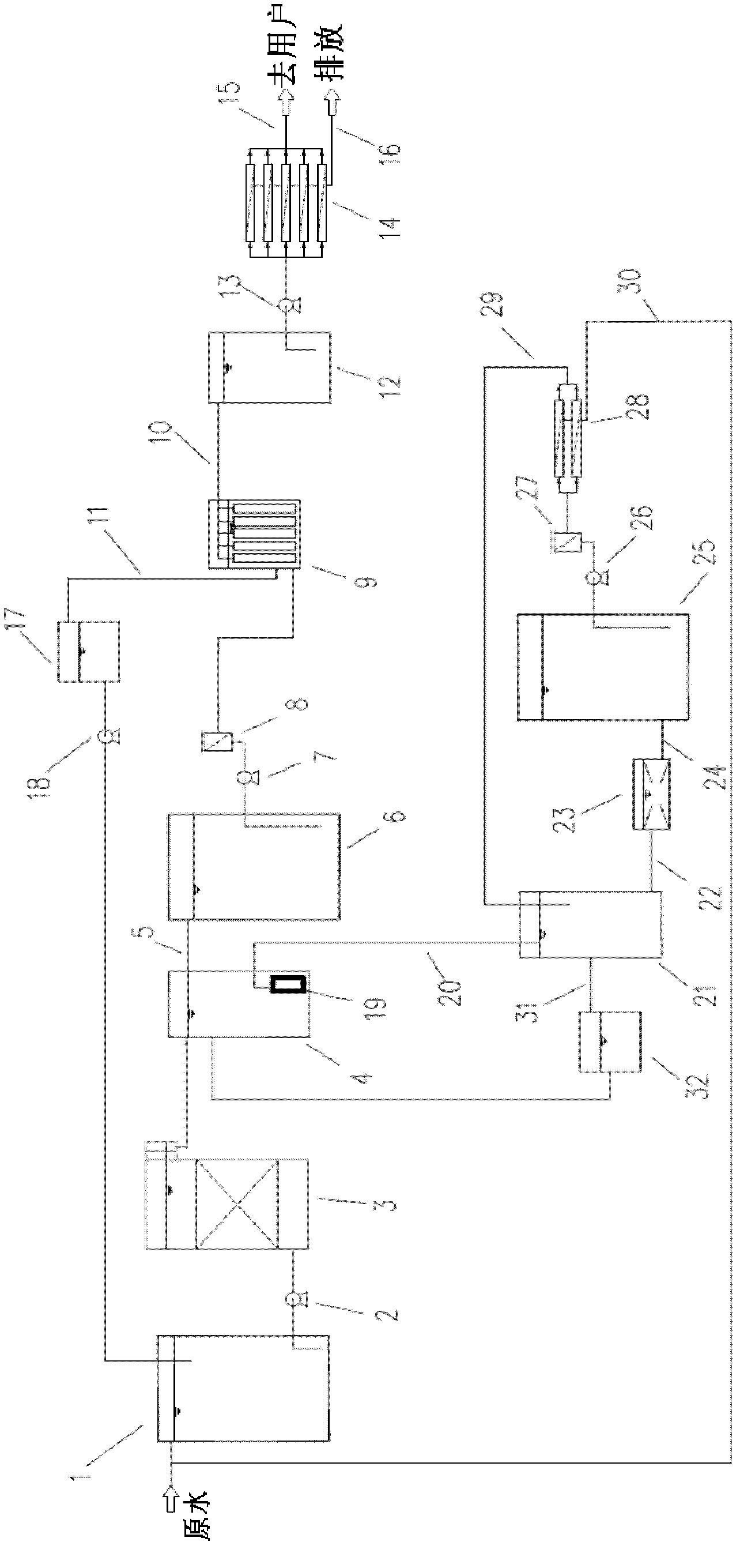

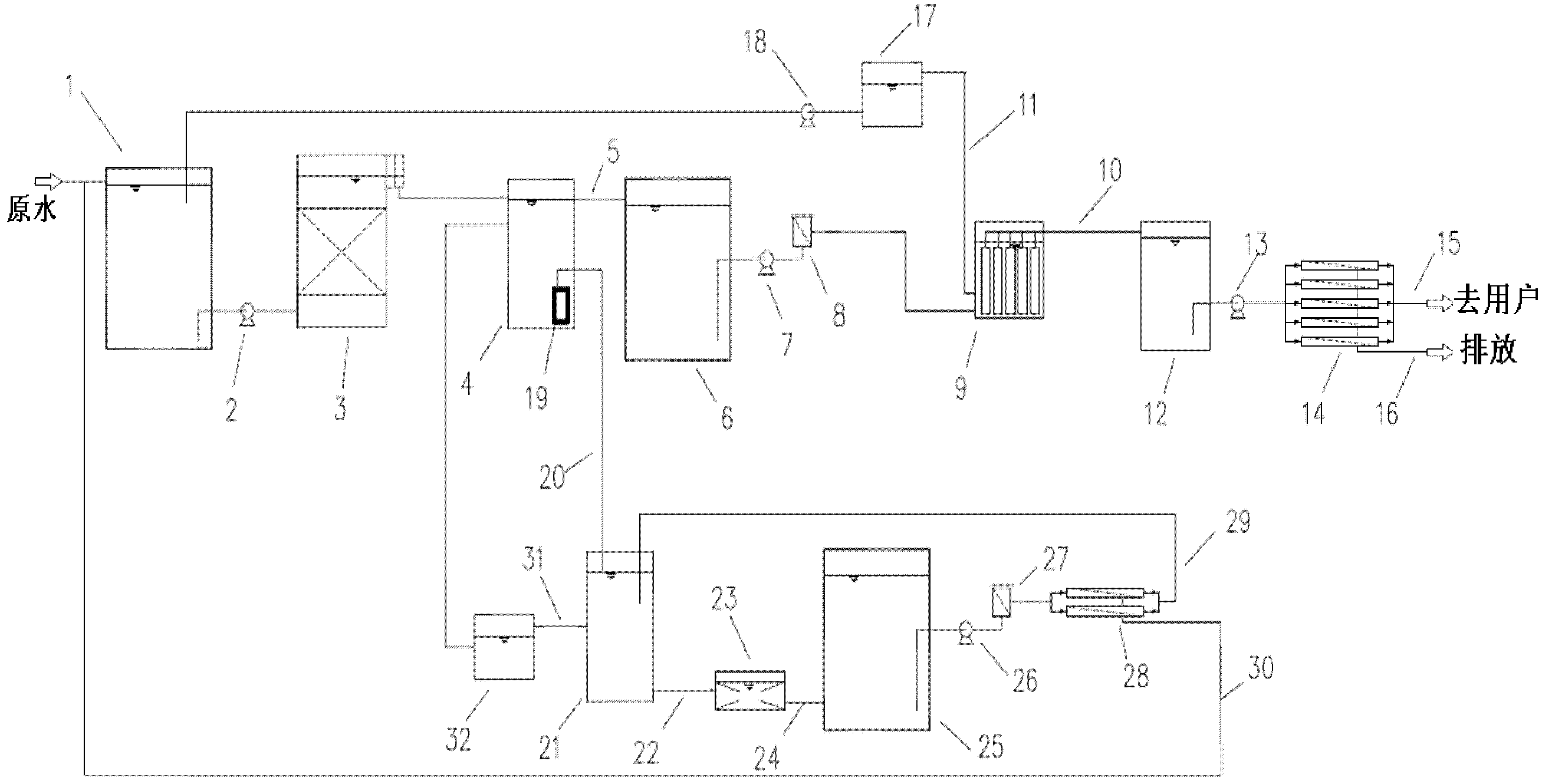

Image

Examples

Embodiment 1

[0085] Follow the steps below for waste disposal.

[0086] a. Pump the wastewater to be treated to the biological aerated filter for biochemical treatment. The COD concentration of the wastewater is 60mg / L. As the filter material of the biological aerated filter, 3-5mm ceramsite (produced by Ma'anshan Huaqi Environmental Protection Technology Development Co., Ltd.), dissolved oxygen concentration ≥ 3mg / L, and aeration intensity 0.13m 3 / m 2 .min, using air-water backwashing, the air washing intensity is 14L / s.m 2 , washing strength is 5L / s.m 2 , the empty bed residence time is 1.5 hours.

[0087] b, using 2-stage adsorption, and passing through magnetic ion exchange resin ( Orica Watercare Company), the biochemically treated wastewater is adsorbed under agitation. At this time, relative to the wastewater, the concentration of the magnetic ion exchange resin is 150ml / L, and the adsorption time of each stage is 15 minutes. The adsorption capacity of the magnetic ion excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com