Method for treating high concentration organic waste water

A technology of organic sewage and treatment methods, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of unstable water quality, low pollutant removal rate and facility occupation Large area and other problems, to achieve the effect of large or small processing capacity, effective cohesion, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

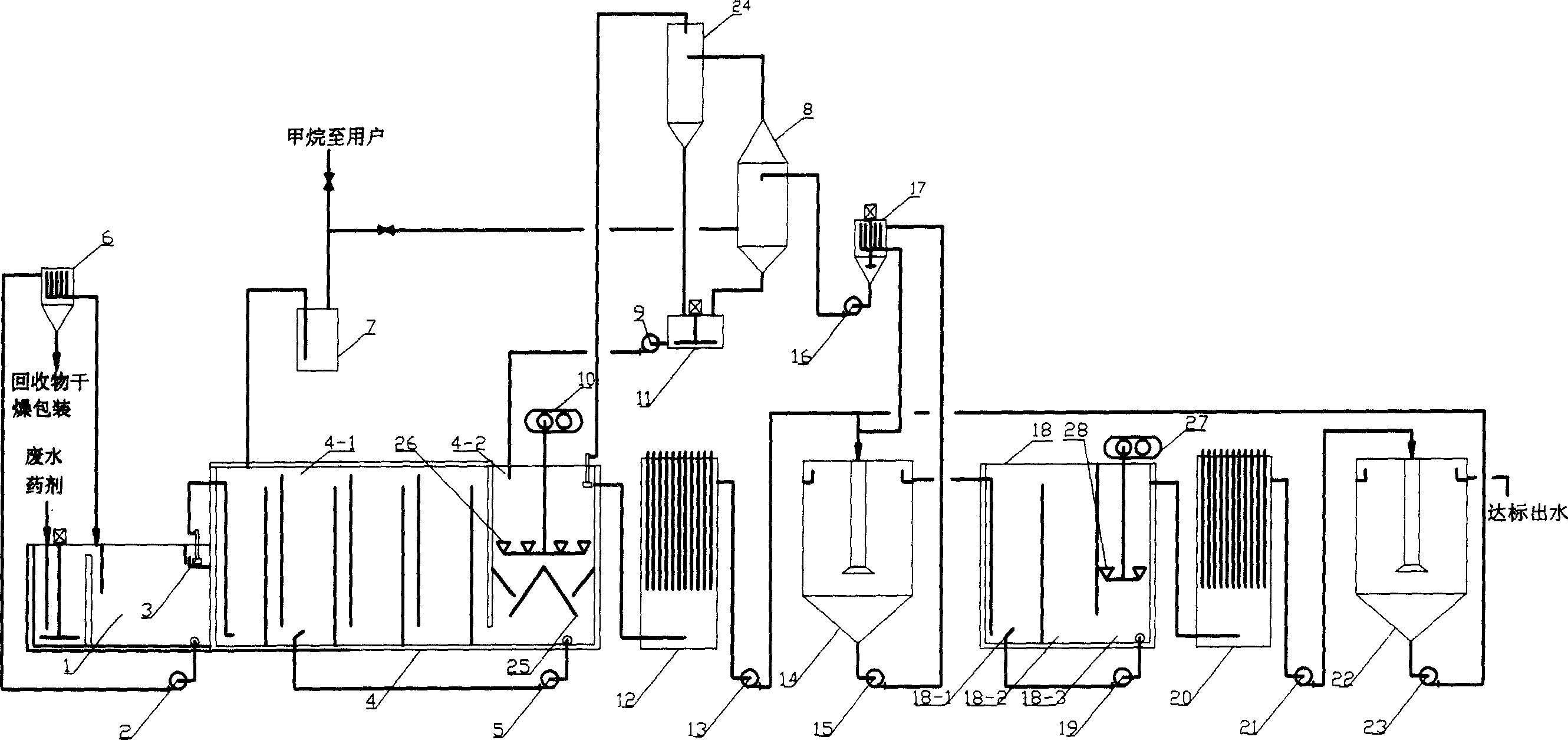

[0030] Embodiment 1: see accompanying drawing.

[0031] A method for treating high-concentration organic sewage, mainly consisting of the following steps:

[0032] a. Pre-treatment: The organic sewage is treated with desanding and slag removal to remove solids; the pre-treatment process includes usually required primary treatment equipment, such as coarse screens, fine screens, grit chambers, etc. These equipments can Design according to the specific situation of the enterprise sewage;

[0033] b. Flocculation and precipitation separation: add flocculants (such as polyacrylamide, silica gel, etc., the flocculants used in the prior art) to the organic sewage, and remove the filter residue through stirring, sedimentation and filtration;

[0034] After desanding and slag removal, the organic sewage first enters the flocculation tank 1, where preliminary flocculation and sedimentation separation is carried out, so as to recover useful substances (such as protein) in the sewage; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com