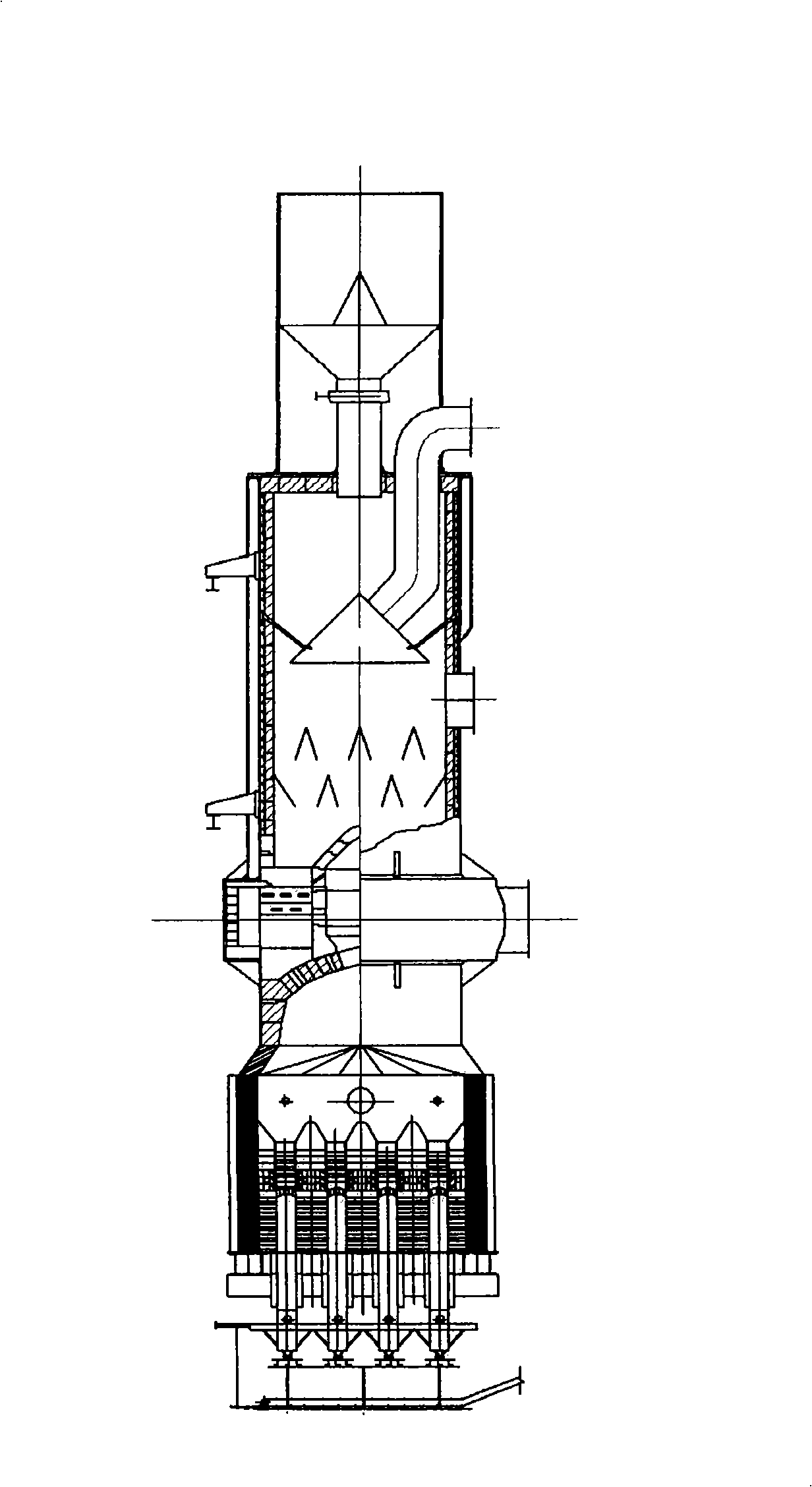

Complete alternation gas retort for treating 300 tons of wax shale mash gas a day

A dry distillation furnace and oil shale technology, which is applied in special forms of dry distillation, coke ovens, petroleum industry, etc., can solve the problems of ineffective use of semi-coke, expensive imported equipment, small daily processing capacity, etc., and prolong life. and continuous working hours, reduced construction investment, and the effect of large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The main points of the specific embodiment of the present invention: one is to ensure that the temperature of the retort section in the furnace is stable at about 550°C, neither too high nor too low, if it is too high, it will cause overheating, if it is too low, it will cause incomplete retort. This can be achieved by properly adjusting the ratio of the 700°C thermal cycle gas entering the middle and the 80°C cold cycle gas entering the lower part. The second is to ensure balanced contact between materials and circulating gas, in order to ensure balanced dry distillation. Therefore, the furnace is equipped with a herringbone distribution board and a flower wall to adjust the direction of the air flow; thirdly, a water seal and a cooling water jacket are installed at the lower part of the furnace, which are used to absorb the heat of semi-coke and prevent the gas from leaking out to protect the environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com