Wet dust removal device and technique for titanium tetrachloride smoke

A technology of titanium tetrachloride and wet dust removal, applied in titanium halide, chemical instruments and methods, separation methods, etc., can solve the problems of high investment and maintenance cost, high failure rate and energy consumption, poor field operation environment, etc. The effect of reducing construction investment and production maintenance costs, improving yield and reducing dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the drawings and specific embodiments.

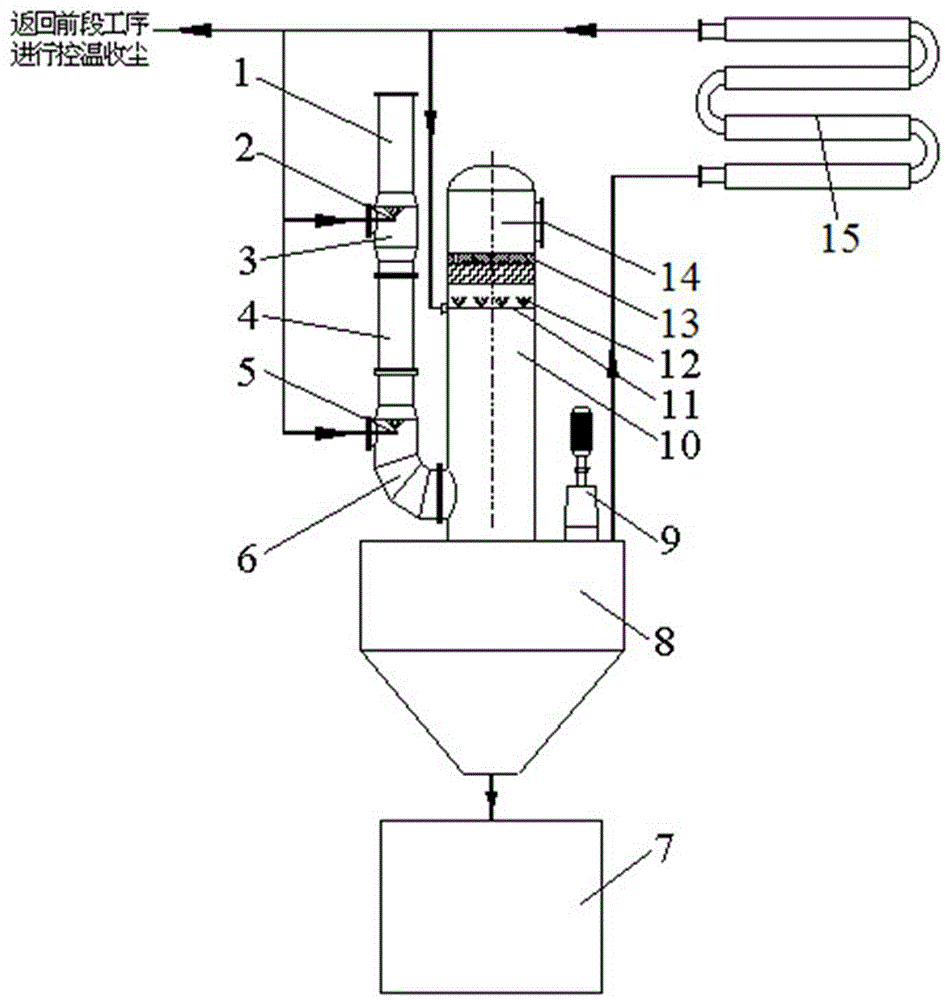

[0017] Such as figure 1 As shown, the device of the present invention for wet dust removal of titanium tetrachloride flue gas includes a circulation tank 8. The bottom of the circulation tank 8 is connected with the underflow tank 7, and the top of the circulation tank 8 is equipped with a circulation pump 9 and a vertical separation Tower 10; the upper part of the side wall of the separation tower 10 is provided with an air outlet 14. The separation tower 10 is sequentially installed with a foam trap 13 and a liquid inlet pipe 11 from top to bottom. The liquid inlet pipe 11 is provided with multiple nozzles facing the foam trap 13 of the washing nozzle 12, the position of the foam trap 13 is lower than the position of the air outlet 14; a second connecting pipe 6 is installed at the lower part of the side wall of the separation tower 10, and one end of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com