Bauxite ore dressed and ore cleaned tailings piling method

A bauxite and tailings technology, applied in chemical instruments and methods, solid waste removal, other chemical processes, etc., can solve the problems of high management and maintenance costs, hidden safety hazards of dam bodies, and large land occupation in the reservoir area. To achieve the effect of reducing construction investment and management and maintenance, reducing hazards and impacts, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

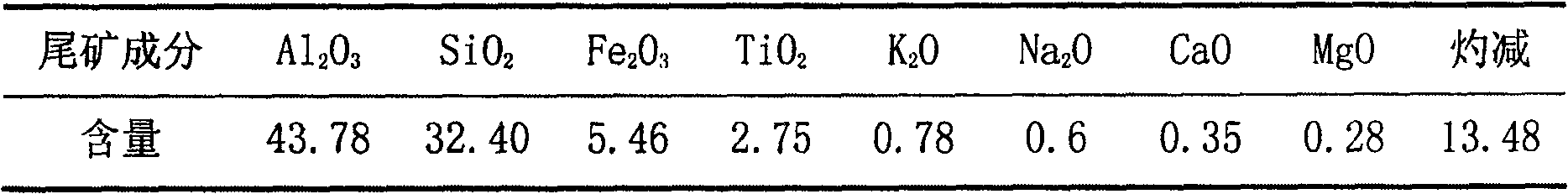

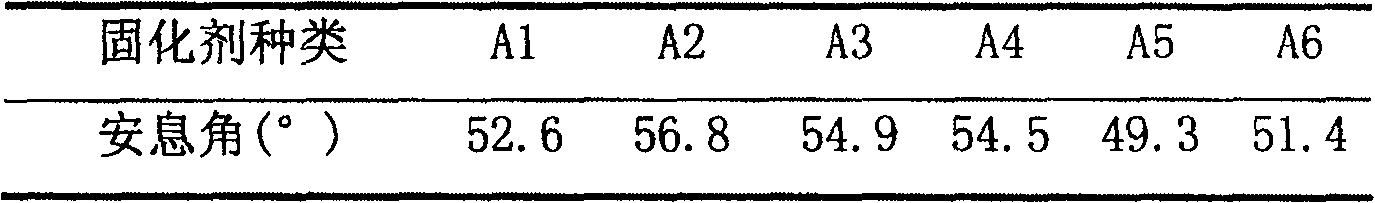

[0020] Taking the beneficiation tailings of Xiaoyi Bauxite Mine in Shanxi Province as samples, the chemical analysis results of the tailings are shown in Table 1, and the particle size distribution of the tailings is shown in Table 2. After medium flocculation and settlement, the underflow concentration is 62.31%, and after the action of 5# dehydrating agent provided by Ciba Company, the concentration of tailings reaches 71.64%. Take 1 ton of tailings from the dehydrated tailings and add the following A1 respectively , A2, A3, A4, A5 and A6 six - 200 mesh curing agent 50 kg, the components of the six curing agents are shown in Table 3, the mechanical stirring time is 10min, and they are discharged and piled up. They are used for the dry stacking effect of tailings See Table 4 for the angle of repose.

[0021] Table 1 Chemical analysis results of beneficiation tailings in Xiaoyi Bauxite Mine (%)

[0022]

[0023] The particle size distribution (%) of table 2 tailings

[00...

Embodiment 2

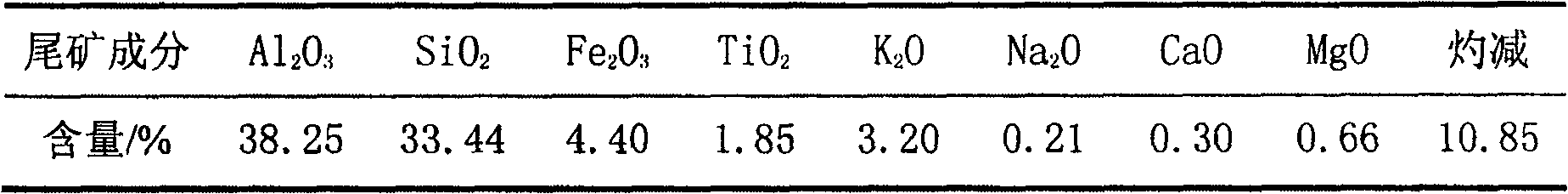

[0030] Taking the beneficiation tailings of Dengfeng Bauxite Mine in Henan as samples, the chemical analysis results of the tailings are shown in Table 5, and the particle size distribution of the tailings is shown in Table 6. After medium flocculation and settlement, the underflow concentration is 65.69%, and after interacting with the 5# dehydrating agent provided by Ciba, the concentration of the tailings reaches 73.37%. Take out 1 ton of tailings from the dehydrated tailings and add the following A1 respectively , A2, A3, A4, A5 and A6 six - 200 mesh curing agent 50 kg, the components of the six curing agents are shown in Table 3, the mechanical stirring time is 10min, and they are discharged and piled up. They are used for the dry stacking effect of tailings See Table 7 for the angle of repose. After the tailings reacted with the A2 curing agent were cured for 2 hours, 4 hours, 8 hours, 24 hours and 72 hours, the curing effect on the tailings was expressed in Table 8 by t...

Embodiment 3

[0040] Taking the washing tailings of Pingguo bauxite in Guangxi as samples, the chemical full analysis results of the tailings are shown in Table 9, and the particle size distribution of the tailings is shown in Table 10. After flocculation and settlement in the tank, the concentration of the underflow was 56.32%. After interacting with the 5# dehydrating agent provided by Ciba, the concentration of the tailings reached 64.52%. Take out 1 ton of tailings from the dehydrated tailings and add them to the table respectively. A1, A2, A3, A4, A5 and A6 six kinds of -200 mesh curing agent 80kg in 3, mechanical stirring time is 10min, discharged and stacked, their effect on dry stacking of tailings is shown in Table 11 by angle of repose.

[0041] The chemical analysis result (%) of table 9 ore washing slime

[0042] Component

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com