Method for removing heavy metal from rice protein through surfactant

A surfactant and composite surfactant technology, applied in the field of removing heavy metals from rice protein through surfactants, can solve the problems of strong acid corrosion resistance, low yield, affecting product taste, etc., and achieve the effect of reducing fat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

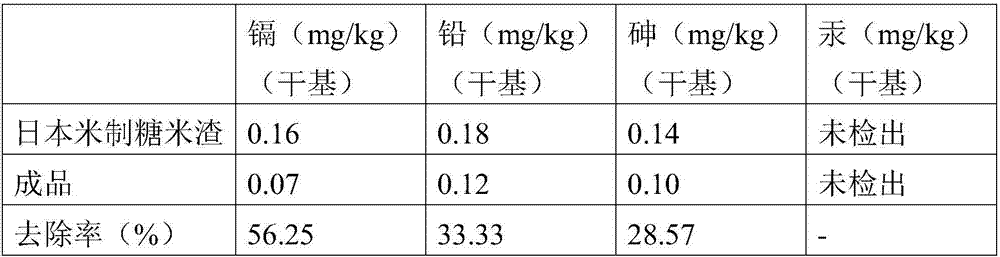

Embodiment 1

[0028] A kind of surfactant removes the method for heavy metal in rice protein, and this method comprises the steps:

[0029] (1) Pre-treatment of sugar-making rice dregs: use Japanese rice-made sugar rice dregs as the initial raw material, add 50°C hot water to adjust the slurry (the mass fraction of rice dregs dry powder is 20%), and add food-grade sodium hydroxide lye to adjust the pH of the slurry to 7.2, soak for 0.5h;

[0030] (2) Add composite surfactant (consumption is 0.05wt% of slurry) in the rice dregs slurry after swelling (consists of: sodium lauryl sulfate 50wt%, sucrose fatty acid ester 40wt%, sodium chloride 10wt%) , after high-strength pulverization treatment (the frequency of the pulverizer is 30Hz), the material passing through the pulverizer is screened, the fineness of the undersize reaches 80 mesh, and the oversize is returned to the mixing tank for pulverization, and the pulverized material is in the reaction tank 40°C heat preservation reaction for 3h;...

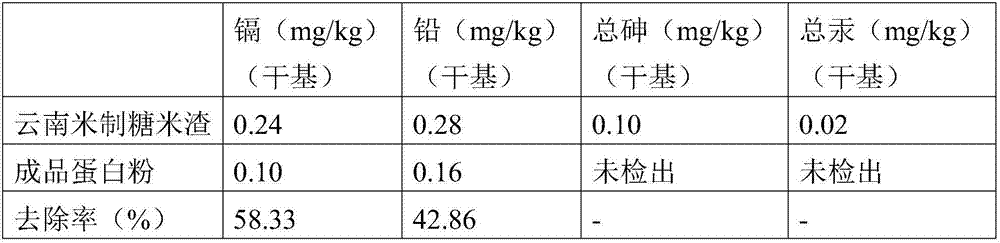

Embodiment 2

[0034] A kind of surfactant removes the method for heavy metal in rice protein, and this method comprises the steps:

[0035] (1) Pre-treatment of sugar-making rice dregs: take Yunnan rice-made sugar rice dregs as the initial raw material, add 70°C hot water to adjust the slurry (the mass fraction of rice dregs dry powder is 10%), and add food-grade sodium hydroxide lye to adjust the pH of the slurry to 7.5, soak for 1h;

[0036] (2) Add composite surfactant (consumption is 0.2wt% of slurry) in the rice dregs slurry after swelling (consists of: sodium lauryl sulfate 55wt%, sucrose fatty acid ester 40wt%, sodium chloride 5wt%) , after high-strength pulverization treatment (the frequency of the pulverizer is 45Hz), the material passing through the pulverizer is sieved, the fineness of the undersize reaches 90 mesh, and the oversize is returned to the mixing tank for further pulverization, and the pulverized material is in the reaction tank Inner 60°C heat preservation reaction ...

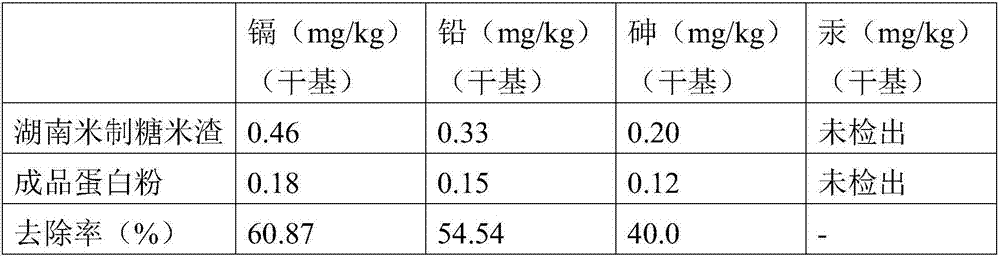

Embodiment 3

[0040] A kind of surfactant removes the method for heavy metal in rice protein, and this method comprises the steps:

[0041] (1) Pre-treatment of sugar-making rice dregs: using Hunan rice-made sugar rice dregs as the initial raw material, adding 80°C hot water to adjust the slurry (the mass fraction of rice dregs dry powder is 5%), and adding food-grade sodium hydroxide lye to adjust the pH of the slurry to 8.0, soak for 1.5h;

[0042] (2) Add composite surfactant (consumption is 0.5wt% of slurry) in the rice dregs slurry after swelling (consists of: sodium lauryl sulfate 60wt%, sucrose fatty acid ester 35wt%, sodium chloride 5wt%) , after high-strength crushing treatment (the frequency of the pulverizer is 60Hz), the material passing through the pulverizer is sieved, the fineness of the undersize reaches 100 mesh, and the oversize is returned to the mixing tank for further pulverization. After pulverization, the material is in the reaction tank Inner 70°C heat preservation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com