Automatic sugar refining method

An automatic, syrupy technology, applied in sugar crystallization, sucrose production, sugar production, etc., can solve the problems of large differences and low standardization, and achieve the effects of reducing energy consumption, reducing labor intensity, and improving sugar quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

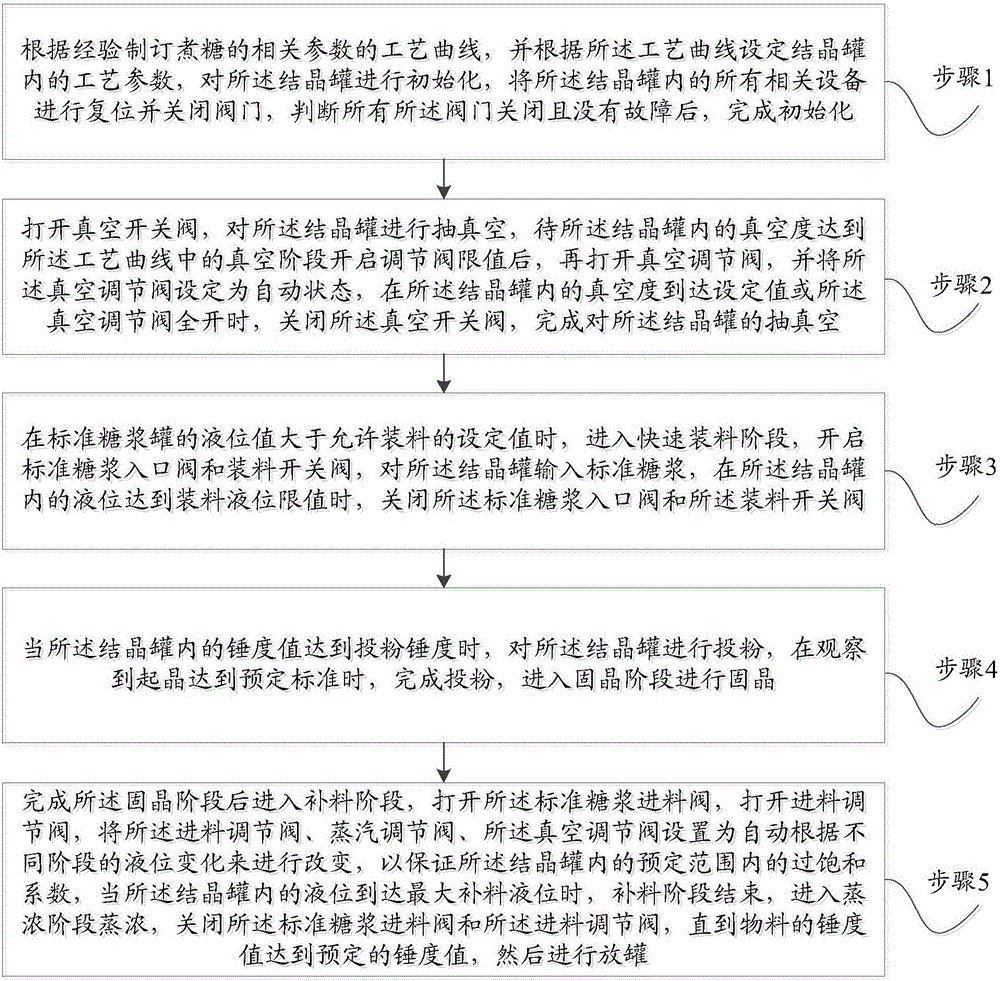

Image

Examples

Embodiment Construction

[0034] As mentioned in the background technology section, in the existing sugar cooking process, all rely on manual experience for manual operation, and human factors have a significant impact on the quality of white granulated sugar. There are differences, or through the adjustment of different industrial controls to perform simple functional division of equipment and manual intervention. Although it can be realized to a certain extent, the differences in each link are relatively large and the degree of standardization is low.

[0035] Based on this, the embodiment of the present invention provides an automatic sugar making method, comprising:

[0036] Step 1, formulate the process curve of the relevant parameters of boiling sugar according to experience, and set the process parameters in the crystallization tank according to the process curve, initialize the crystallization tank, and reset all related equipment in the crystallization tank And close the valve, after judging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com