Low-frequency damping visco-elastic material

A viscoelastic, low-frequency technology, applied in the field of viscoelastic materials with low frequency vibration and high energy consumption, can solve the problems that the aging resistance of viscoelastic materials is difficult to meet the requirements, and the durability of viscoelastic materials is not very good, so as to overcome the adhesion Poor performance, good energy dissipation characteristics, and the effect of improving damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A low-frequency shock-absorbing viscoelastic material of the present invention is formed by mixing main rubber, reinforcing system, vulcanization system, anti-aging system and softening-plasticizing system, wherein the main rubber is bromobutyl rubber, and the reinforcing system is High wear-resistant carbon black and 100-200 mesh graphite powder mixed system, vulcanization system is vulcanized resin, zinc oxide, magnesium oxide and stearic acid, anti-aging system is rubber anti-aging agent MBZ and anti-aging agent Naugard445, softening-plasticizing system is TOTM (trioctyl trimellitate) and Escorez 2203LC resin. The specific formula is as follows:

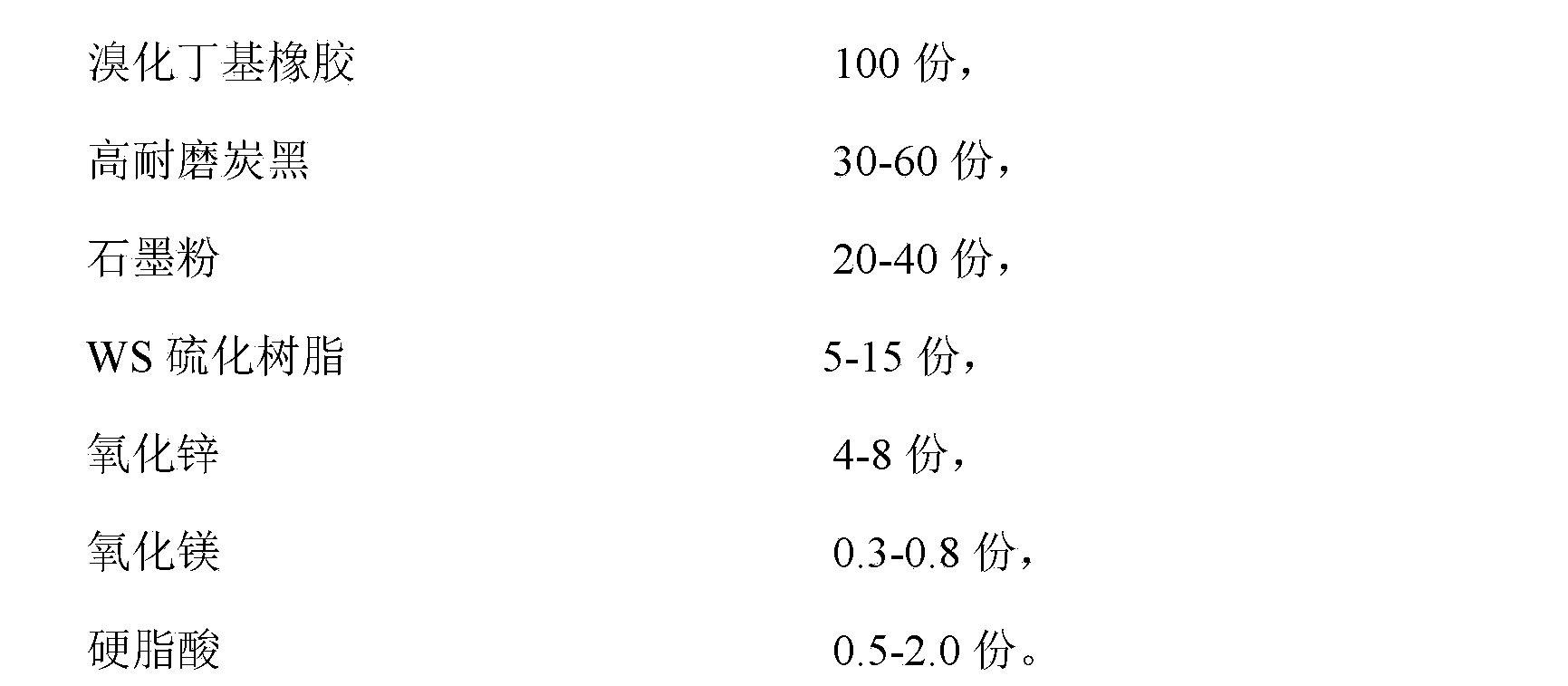

[0022] Recipe one:

[0023]

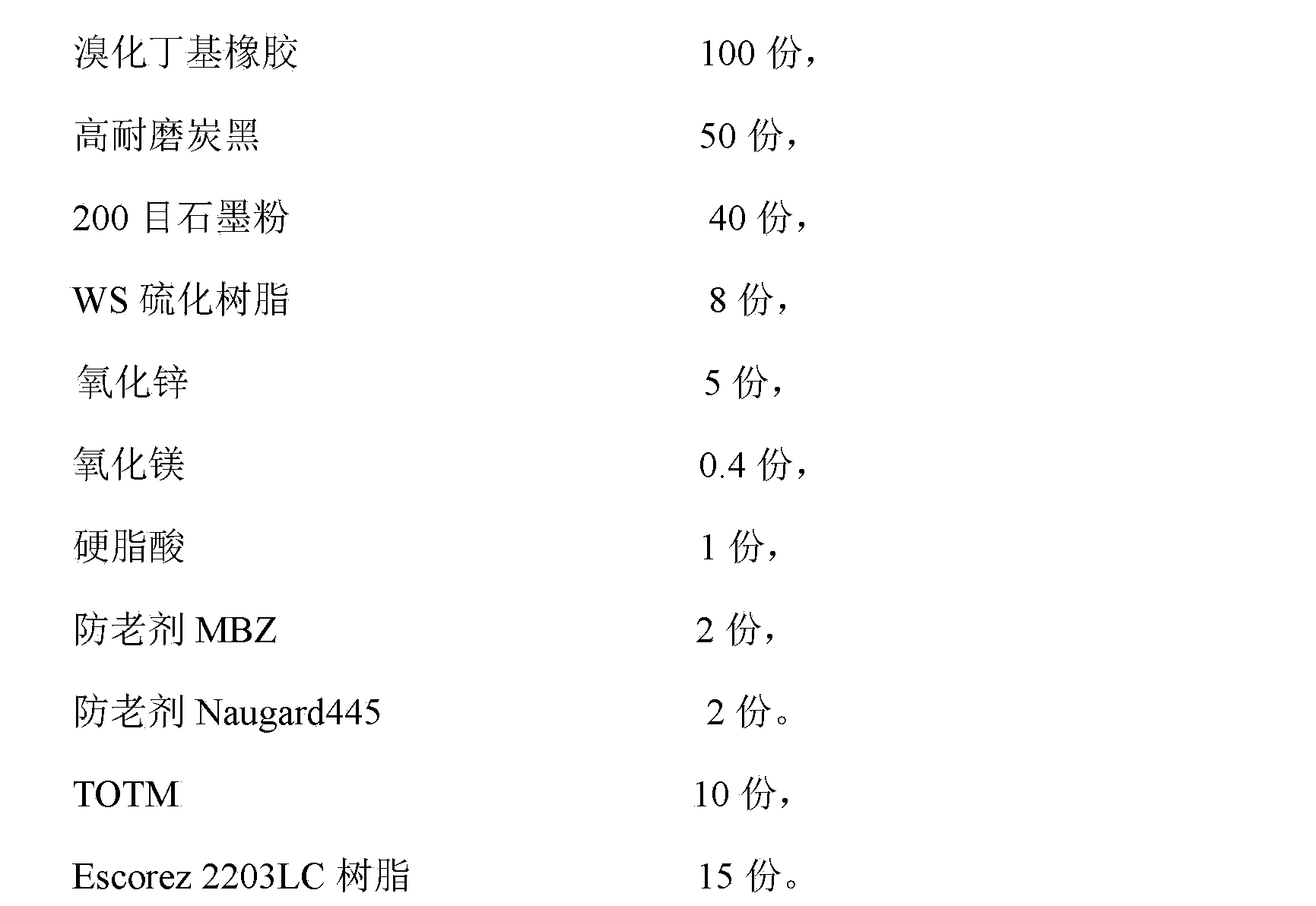

[0024] Recipe 2:

[0025]

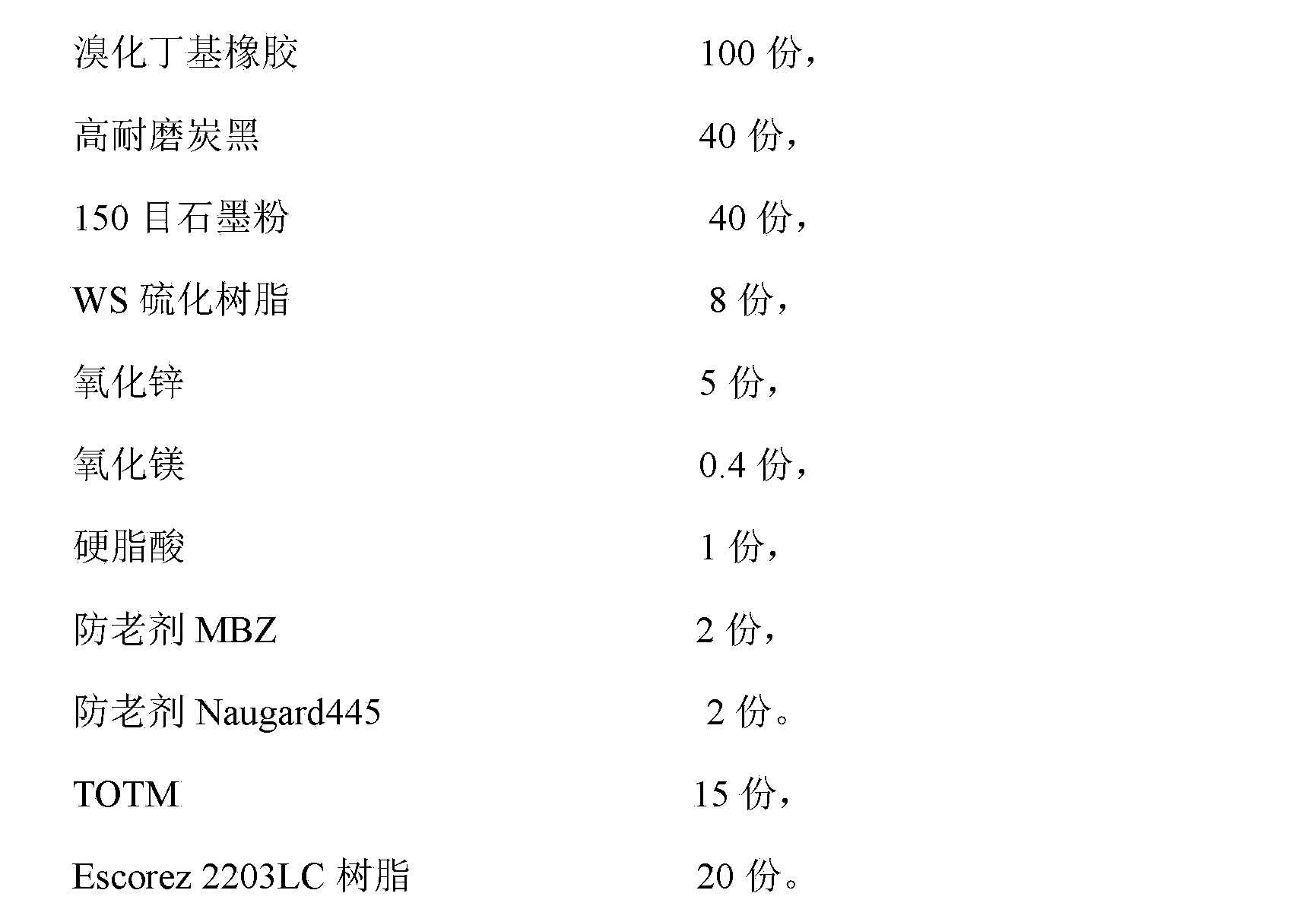

[0026] Recipe three:

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss factor | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com