Sound insulation material composition and vehicle sound insulation sheet

A technology of sound insulation material and composition, which is applied in the field of auto parts, can solve the problem that the sound insulation effect cannot meet the requirements, and achieve the effect of increasing energy loss and increasing loss factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

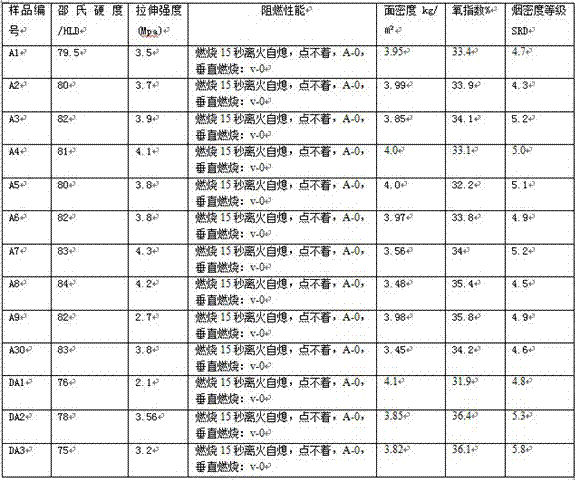

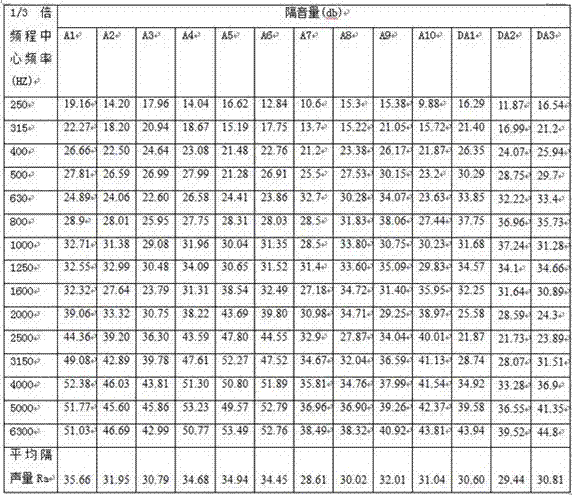

Examples

Embodiment 1

[0025] (1) Weigh 6kg of dolomite (the average particle size of dolomite is 200 mesh), 40kg of barium sulfate, and 0.5kg of silane coupling agent, and mix them in a mixer at 110°C for 5 minutes;

[0026] (2) Weigh 10kg of mica powder (the average particle size of mica powder is 325mm mesh), 3kg of paraffin oil and mix them evenly in a plastic container;

[0027] (3) Weigh 10kg of EVA, 5Kg of propylene-based elastomer (Vistamaxx 6102), 3kg of vinyl-based elastomer (Engage8150), 2kg of linear low-density polyethylene (LLDPE GA574-000), 1kg of EVA grafted maleic anhydride, Combustion agent (zinc borate 6kg, magnesium hydroxide 2kg, aluminum hydroxide 2kg) 10kg, carbon black 1kg and 2.3kg of stearic acid, zinc stearate, calcium oxide, anti-aging agent (dilauryl thiodipropionate ), put the mixture obtained in step (1) and step (2) together in a banbury mixer, set the temperature in the banbury mixer to 120°C, and banbury time for 15 minutes;

[0028] (4) The mixed material after ba...

Embodiment 2

[0030]Adopt the method identical with embodiment 1 to prepare sound insulation sheet, difference is, the average particle diameter of the dolomite that adopts in step (1) is 325 orders, and in step (2), the average particle diameter of the mica powder that adopts is 600 mesh; the vehicle sound-insulating sheet A2 of Example 2 was prepared.

Embodiment 3

[0032] Adopt the method identical with embodiment 1 to prepare sound insulation sheet, difference is that the average particle diameter of the dolomite that adopts in step (1) is 600 orders, and in step (2), the average particle diameter of the mica powder that adopts is 800 mesh; the vehicle sound-insulating sheet A3 of Example 3 was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com