High-temperature underwater sound transmission rubber material and preparation method thereof

A sound-permeable rubber and high-performance technology, which is applied in the field of preparation of high-performance underwater acoustic sound-permeable rubber materials, can solve problems such as difficult to have high water tightness, achieve excellent physical and mechanical properties, improve water tightness, and strong physical and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

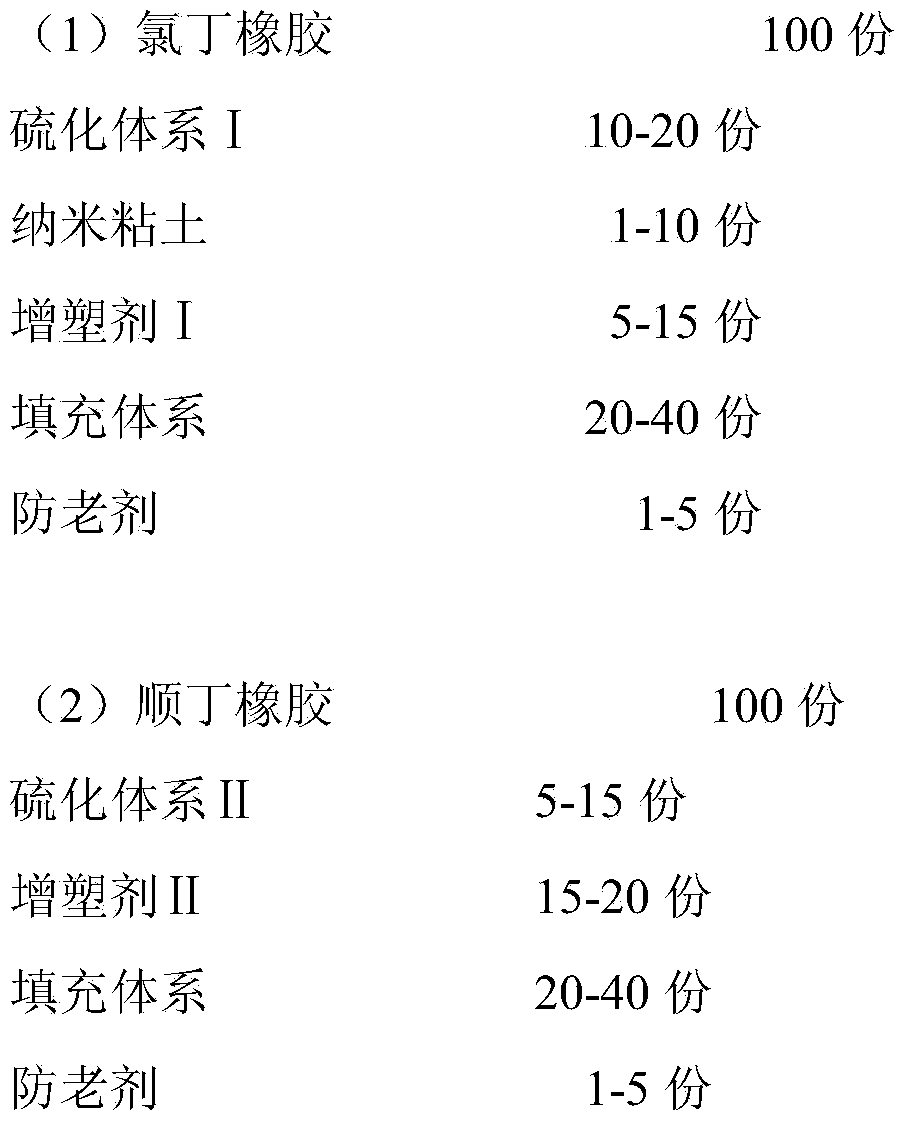

[0029] Embodiment 1-5: A high-performance underwater acoustic sound-permeable rubber material, characterized in that: the parts by weight of each raw material are composed of:

[0030] Neoprene (CR322)

100 copies

Butadiene rubber (BR9000)

100 copies

5 copies

5 copies

5 copies

1 copy

Accelerator NA-22

1.5 servings

Accelerator PZ

1.5 servings

Accelerator M

0.5 parts

Accelerator CZ

2 copies

Accelerator TT

0.5 parts

Antiager D

2 copies

Antiager D

2 copies

DOP

12 copies

clay

5 copies

Coumarone resin

5 copies

Carbon black N330

30 copies

Carbon black N330

30 copies

Aromatic oil

10 copies

1 copy

[0031] The neoprene and butadiene rubber are plasticized at room temperature with a double-roller mill respectively, and after passing the rol...

Embodiment 6-7

[0035] Embodiment 6-7: A high-performance underwater sound-permeable rubber material, characterized in that: the parts by weight of each raw material are composed of:

[0036] Neoprene (CR121, CR321) *

[0037] Note * , the combination of CR (CR121) and BR in the above formula is recorded as Example 6; the combination of CR-322 and BR is recorded as Example 7; the combination ratio of CR and BR is 70 / 30.

[0038] Preparation method: According to the preparation method of Example 1, a sound-permeable rubber sample was made, and its properties were tested as follows:

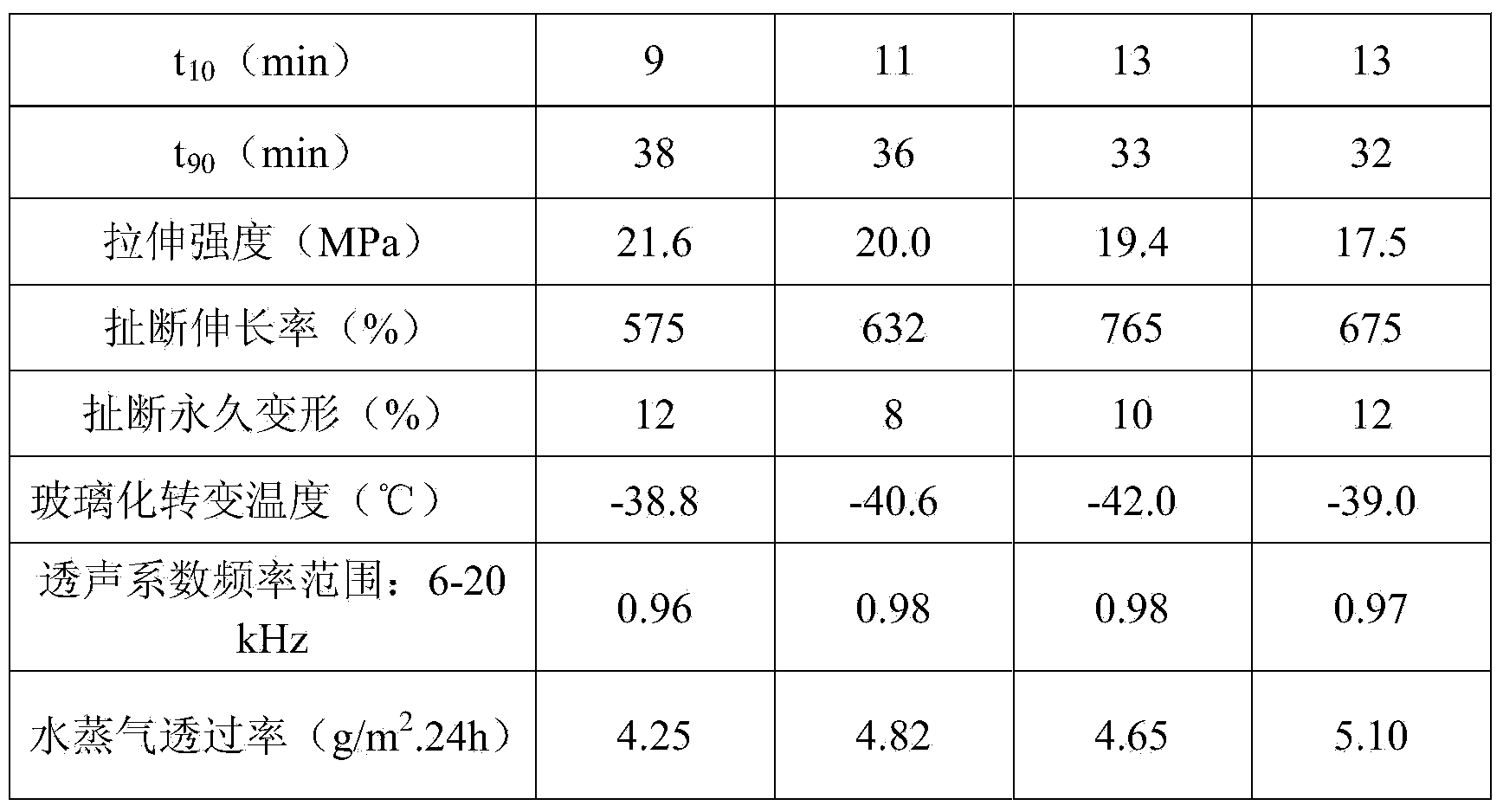

[0039] indicators

[0040] The sound-permeable material of the present invention can be used as a cladding material for underwater detection devices such as ship underwater acoustic equipment and seabed oil exploration equipment.

Embodiment 8-11

[0041] Embodiment 8-11: A high-performance underwater acoustic sound-permeable rubber material, characterized in that: the parts by weight of each raw material are composed of:

[0042] Neoprene (CR122)

100 copies

Butadiene rubber (BR9000)

100 copies

5 copies

Zinc oxide

5 copies

5 copies

1 copy

Accelerator NA-22

1.5 servings

Accelerator PZ

1.5 servings

Accelerator M

0.5 parts

Accelerator CZ

2 copies

Accelerator TT

0.5 parts

Antiager D

2 copies

Antiager D

2 copies

DOP

12 copies

clay

1, 2, 8, 10 copies

Coumarone resin

5 copies

Carbon black N330

30 copies

Carbon black N330

30 copies

Aromatic oil

10 copies

1 copy

[0043] Note * , the ratio of CR and BR in the above formula is 70 / 30. According to the parts 1, 2, 8 and 10 parts of clay added i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com