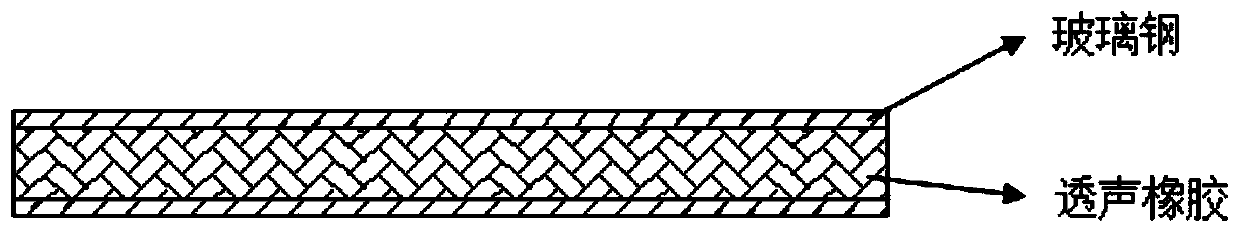

A kind of rubber material, its preparation method and sonar deflector cover plate comprising it

A technology of rubber materials and rubber raw materials, which is applied to rubber layered products, chemical instruments and methods, transportation and packaging, etc., can solve the requirements that cannot simultaneously meet the requirements of sound transmission stiffness, reduce the sound transmission performance of the diversion shell plate, Acoustic scattering and other problems, to achieve the effect of excellent conventional physical and mechanical properties, increase stiffness, and reduce flow-induced noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

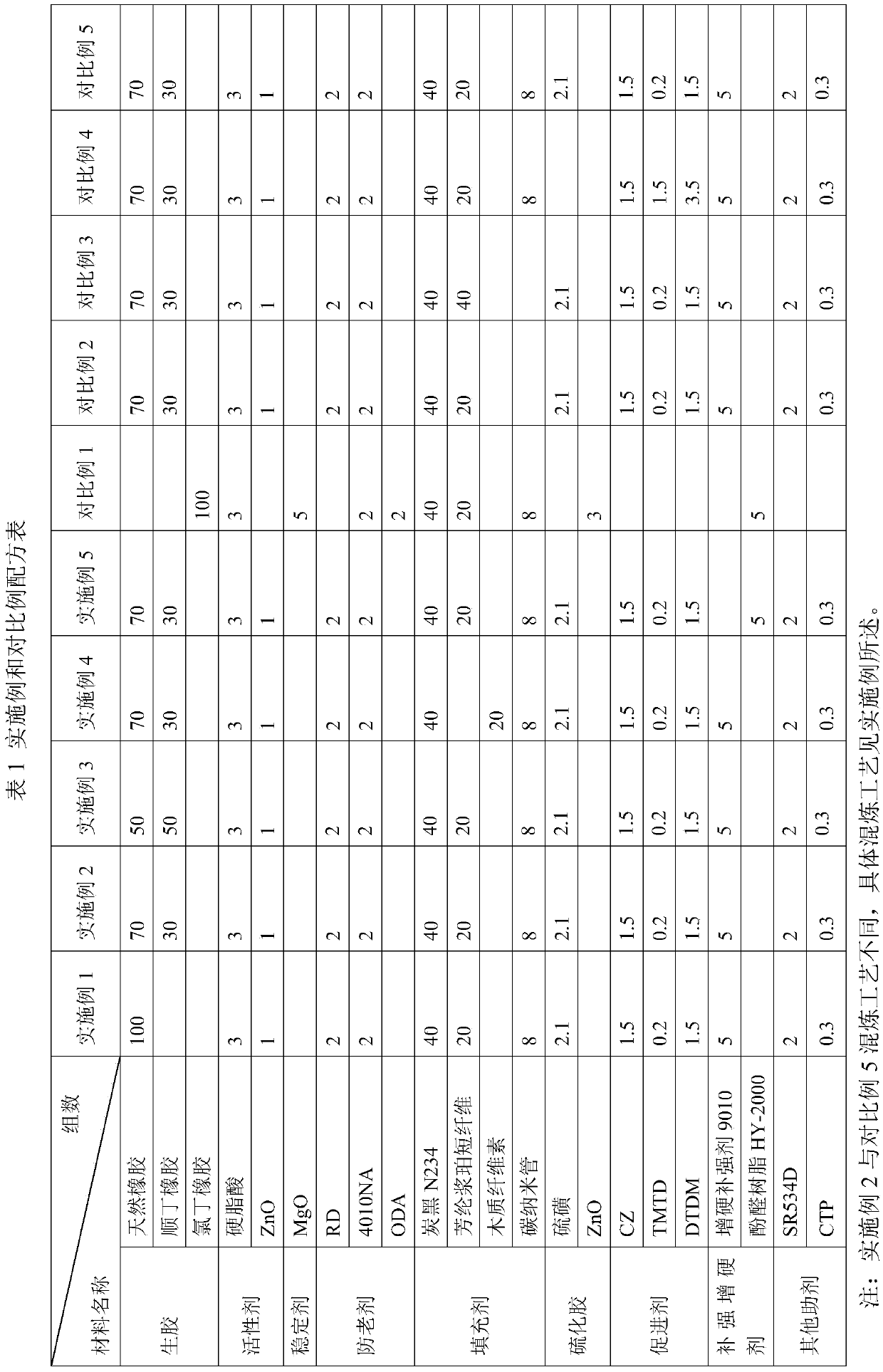

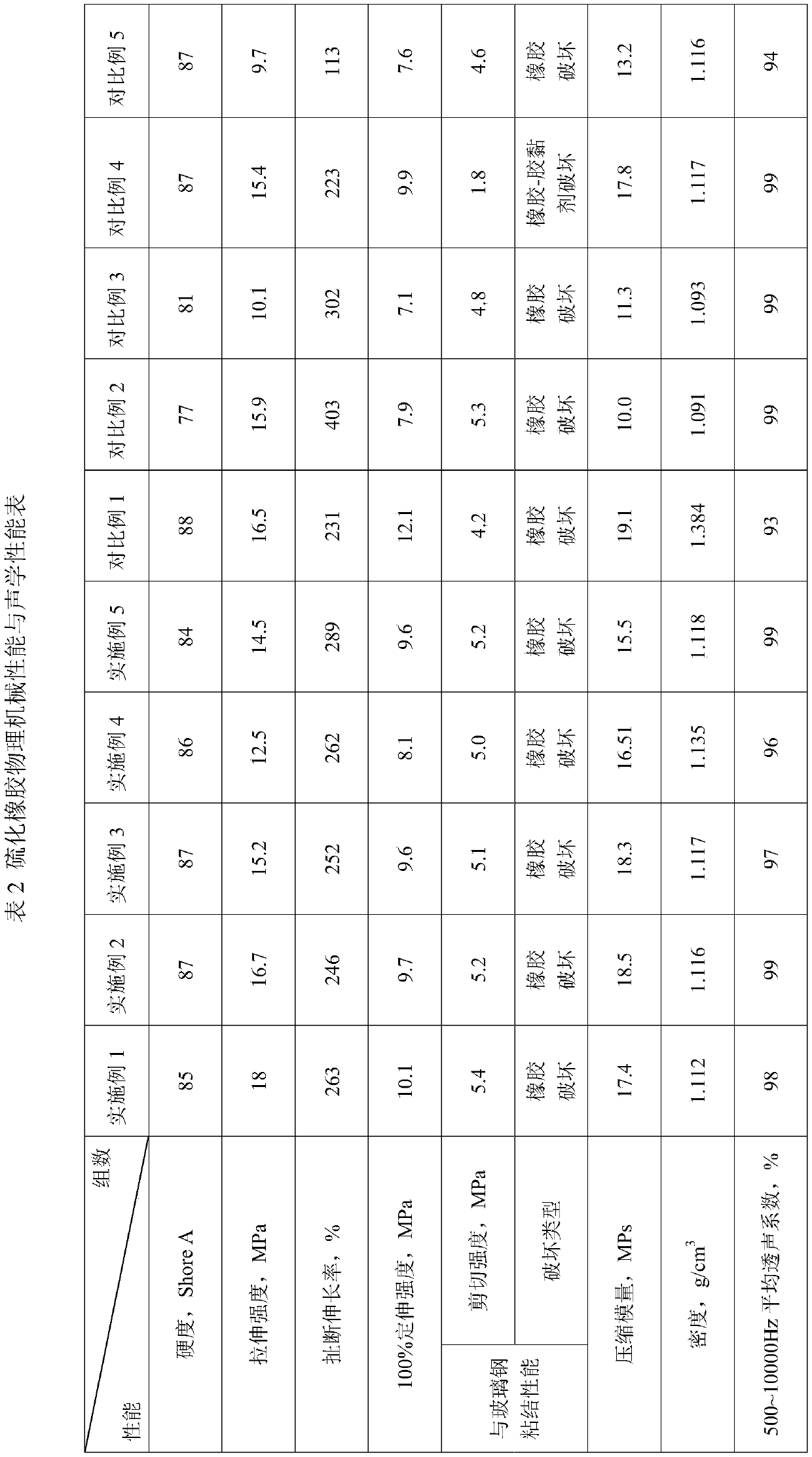

[0048] Configure raw materials according to the following table 1, 100 parts by mass of natural rubber, vulcanization activator (3 parts by mass of zinc oxide, 1 part by mass of stearic acid), antioxidant (2 parts by mass each of RD, 4010NA), reinforcing agent (carbon black 40 mass parts of N234), 20 mass parts of aramid pulp amber short fibers, 8 mass parts of carbon nanotubes and 5 mass parts of hardening and reinforcing agent 9010 are put into the internal mixer for mixing, and the mixing temperature is 100 DEG C. The mixing time is 3 minutes; then the material is fed to the open mill, and the open mill is used for thin pass, the roller distance is 1mm, and the thin pass is about 10 times until the light yellow or white fibers that can be observed by the naked eye disappear, and then the Put the mixed rubber into the internal mixer, add 2.1 parts by mass of vulcanizing agent (common sulfur), 3.2 parts by mass of accelerators (CZ, TMTD and DTDM), 2 parts by mass of anti-rever...

Embodiment 2

[0051] Raw materials are configured according to the following table 1, natural rubber and butadiene rubber (70 / 30 parts by mass), vulcanization activator (3 parts by mass of zinc oxide, 1 part by mass of stearic acid), anti-aging agent (2 parts by mass of RD, 4010NA) , reinforcing agent (40 mass parts of carbon black N234), 20 mass parts of aramid pulp amber short fibers, 8 mass parts of carbon nanotubes and 5 mass parts of hardening and reinforcing agent 9010 are put into the banbury mixer, carry out mixing, The mixing temperature is 100°C, and the mixing time is 3 minutes; then the material is fed to the open mill, and the open mill is used for thin pass, the roller distance is 1mm, and the pass is about 10 times, until the light yellow or Until the white fibers disappear, put the mixed rubber into the internal mixer, add 2.1 parts by mass of vulcanizing agent (common sulfur), 3.2 parts by mass of accelerators (CZ, TMTD and DTDM) in total, and anti-reversion agent (SR534D) 2...

Embodiment 3

[0054] Raw materials are configured according to the following table 1, natural rubber and butadiene rubber (50 / 50 parts by mass), vulcanization activator (3 parts by mass of zinc oxide, 1 part by mass of stearic acid), antioxidant (2 parts by mass of RD, 4010NA) , reinforcing agent (40 mass parts of carbon black N234), 20 mass parts of aramid pulp amber short fibers, 8 mass parts of carbon nanotubes and 5 mass parts of hardening and reinforcing agent 9010 are put into the banbury mixer, carry out mixing, The mixing temperature is 100°C, and the mixing time is 3 minutes; then the material is fed to the open mill, and the open mill is used for thin pass, the roller distance is 1mm, and the pass is about 10 times, until the light yellow or Until the white fibers disappear, put the mixed rubber into the internal mixer, add 2.1 parts by mass of vulcanizing agent (common sulfur), 3.2 parts by mass of accelerators (CZ, TMTD and DTDM) in total, and anti-reversion agent (SR534D) 2 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com