Fiber spray coating structure with surface coating and preparation method thereof

A fiber spraying and surface coating technology, which can be applied to devices and coatings that apply liquid to the surface, and can solve problems such as no decorative effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

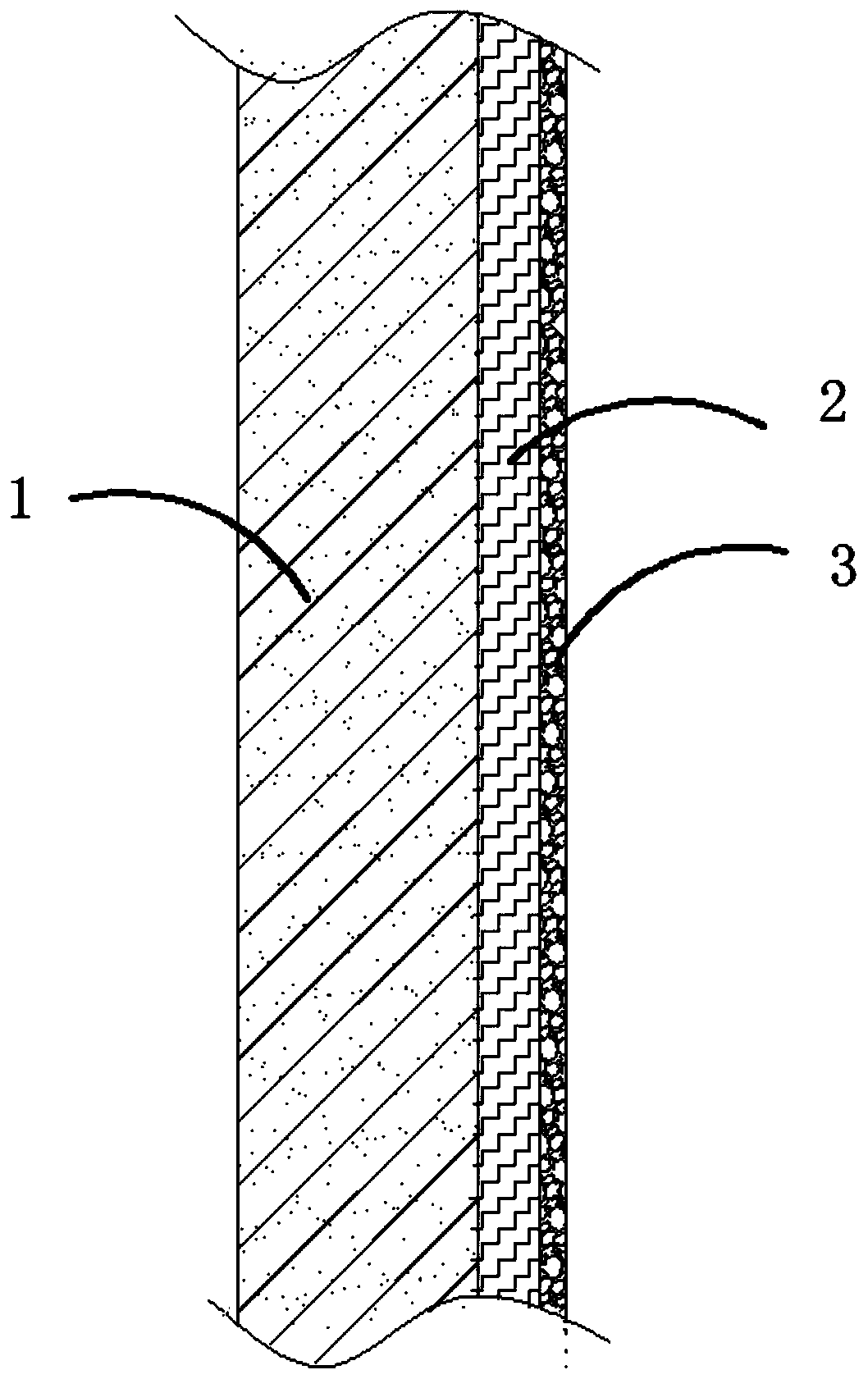

Embodiment 1

[0043] A fiber spraying structure with a top coating, comprising a fiber spraying layer 2 coated on the surface of the base layer 1, and further comprising a top coating 3, the top coating 3 coated on the fiber spraying Layer 2 surface. The surface coating layer 3 contains surface layer particles. The surface coating 3 is made by doping the surface layer particles into the surface layer adhesive, and the mass ratio of the surface layer particles and the surface layer adhesive is 3:1. In parts by weight, the surface layer adhesive includes redispersible latex powder and surface layer auxiliary materials. The surface layer auxiliary materials include solid particles and thickening materials, wherein the redispersed latex powder: solid particles: thickening material The mass ratio is 50:50:0.1. The redispersible latex powder is vinyl acetate ethylene copolymer latex powder, the solid particles are calcium powder, and the thickening material is cellulose. There are pores between...

Embodiment 2

[0049] A fiber spraying structure with a top coating, comprising a fiber spraying layer 2 coated on the surface of the base layer 1, and further comprising a top coating 3, the top coating 3 coated on the fiber spraying Layer 2 surface. The surface coating layer 3 contains surface layer particles. The surface coating layer 3 is made by doping the surface layer particles into the surface layer adhesive, and the mass ratio of the surface layer particles and the surface layer binder is 18:3. In parts by weight, the surface layer adhesive includes redispersible latex powder and surface layer auxiliary materials. The surface layer auxiliary materials include solid particles and thickening materials, wherein the redispersed latex powder: solid particles: thickening material The mass ratio is 300:200:3.0. The redispersible latex powder is made by mixing vinyl chloride vinyl laurate copolymer latex powder and vinyl acetate homopolymer latex powder, the solid particles are made by mix...

Embodiment 3

[0055] A fiber spraying structure with a top coating, comprising a fiber spraying layer 2 coated on the surface of the base layer 1, and further comprising a top coating 3, the top coating 3 coated on the fiber spraying Layer 2 surface. The surface coating layer 3 contains surface layer particles. The surface coating layer 3 is made by doping the surface layer particles into the surface layer adhesive, and the mass ratio of the surface layer particles and the surface layer binder is 3:3. In parts by weight, the surface layer adhesive includes redispersible latex powder and surface layer auxiliary materials. The surface layer auxiliary materials include solid particles and thickening materials, wherein redispersed latex powder: solid particles: thickening material The mass ratio is 80:60:2. The redispersible latex powder is vinyl acetate ethylene copolymer latex powder, the solid particles are calcium powder, and the thickening material is cellulose. There are pores between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com