Preparation method of graphene composite silicon-carbon-nitrogen precursor ceramics

A graphene composite and precursor ceramic technology, applied in the field of microwave absorption, can solve the problems such as no reports on graphene composite silicon carbon nitride precursor ceramics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

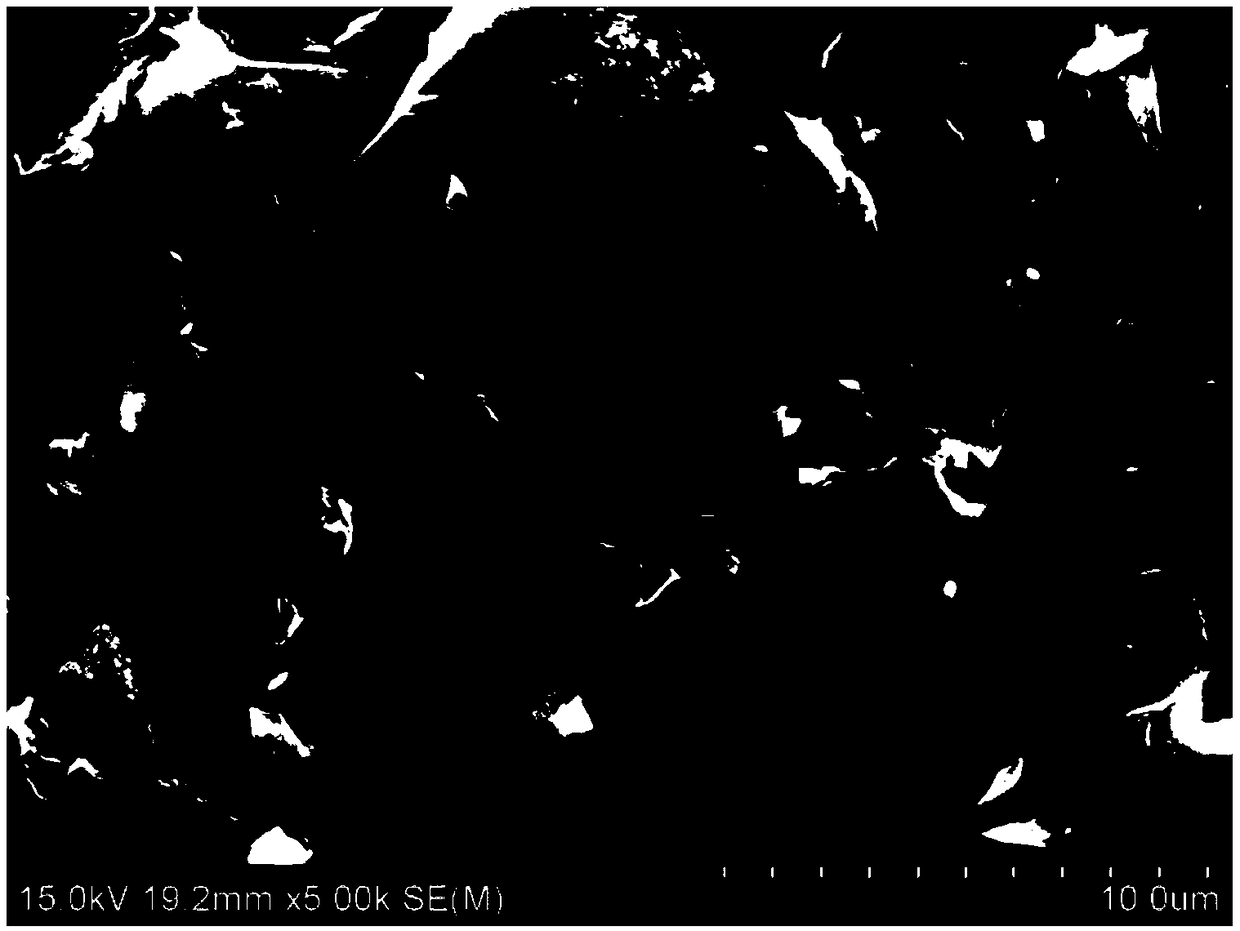

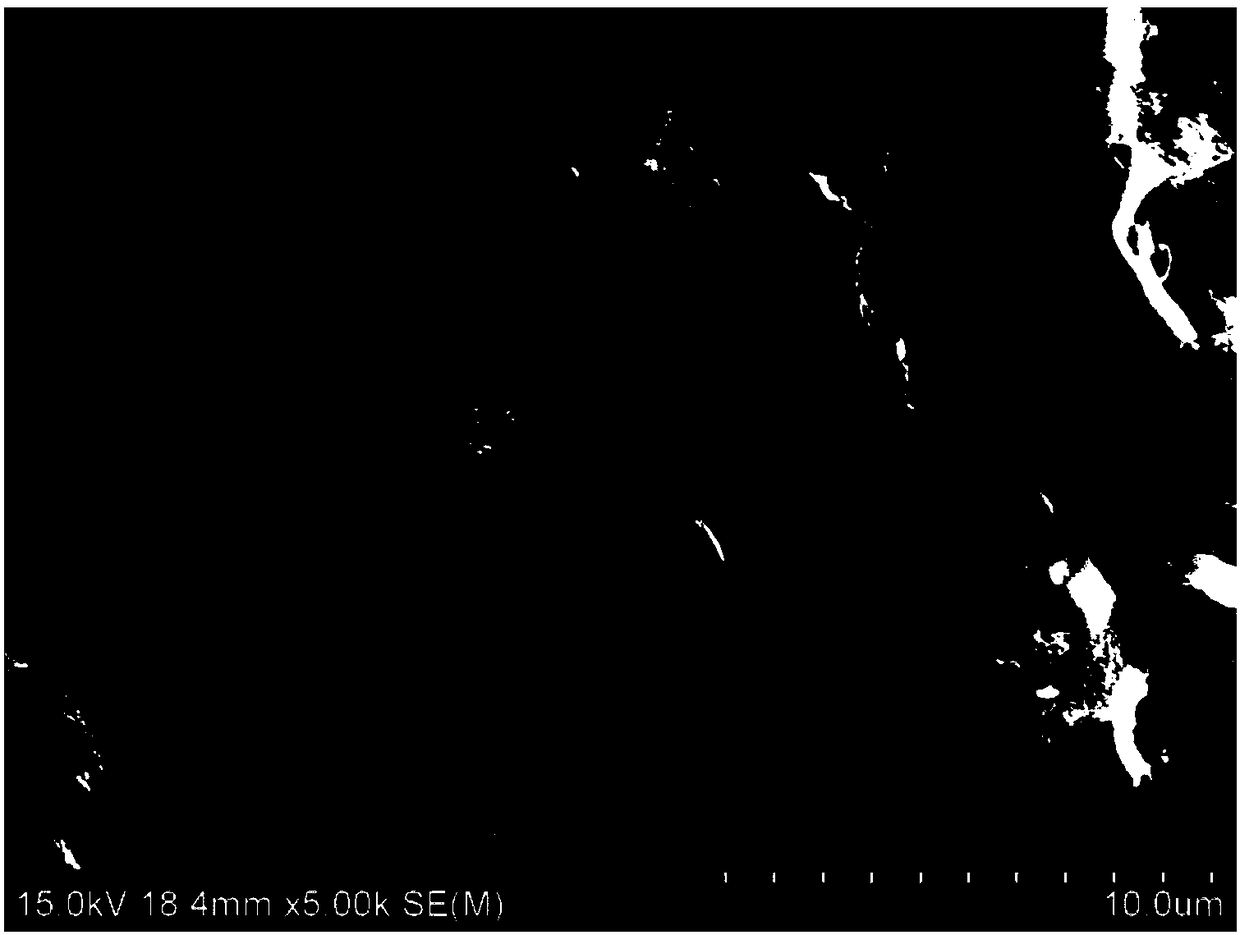

Image

Examples

Embodiment Construction

[0015] A kind of precursor method prepares the method for graphene composite silicon carbon nitrogen precursor ceramics, comprises steps as follows:

[0016] (1) Mixing: in N 2 Under the atmosphere, stir polysilazane (PSZ) and graphene evenly to obtain a mixed solution;

[0017] The polysilazane: graphene is formulated according to the mass ratio of 60% to 95%: 40% to 5%;

[0018] (2) Cross-linking curing: the mixed solution obtained in step (1) is cured at a heating rate of 3-5°C / min from room temperature to 300-800°C for 1-8 hours;

[0019] (3) Pulverizing and ball milling: pulverizing and ball milling the solidified material obtained in step (2) in a vibrating ball mill, and passing through a 100-200 mesh sieve;

[0020] (4) Granulation molding: press the powder obtained in step (3) under a pressure of 5MPa to 15MPa, cold isostatic pressing, 150 to 250MPa, and hold the pressure for 200 to 400s to obtain a green body;

[0021] (5) heat treatment: the green body obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com