Light-weight broadband electromagnetic wave absorbing material and preparation method thereof

A technology for absorbing materials and electromagnetic waves, which is applied in the field of light-weight broadband electromagnetic wave absorbing materials and their preparation, can solve problems such as single use, difficult electromagnetic wave broadband and high-efficiency absorption, and achieve simple production process, good absorption effect, and strong absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

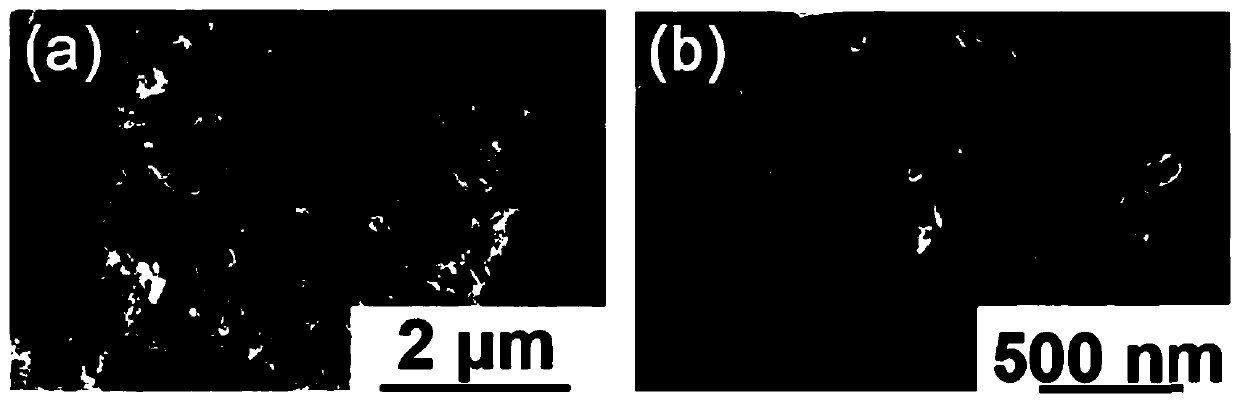

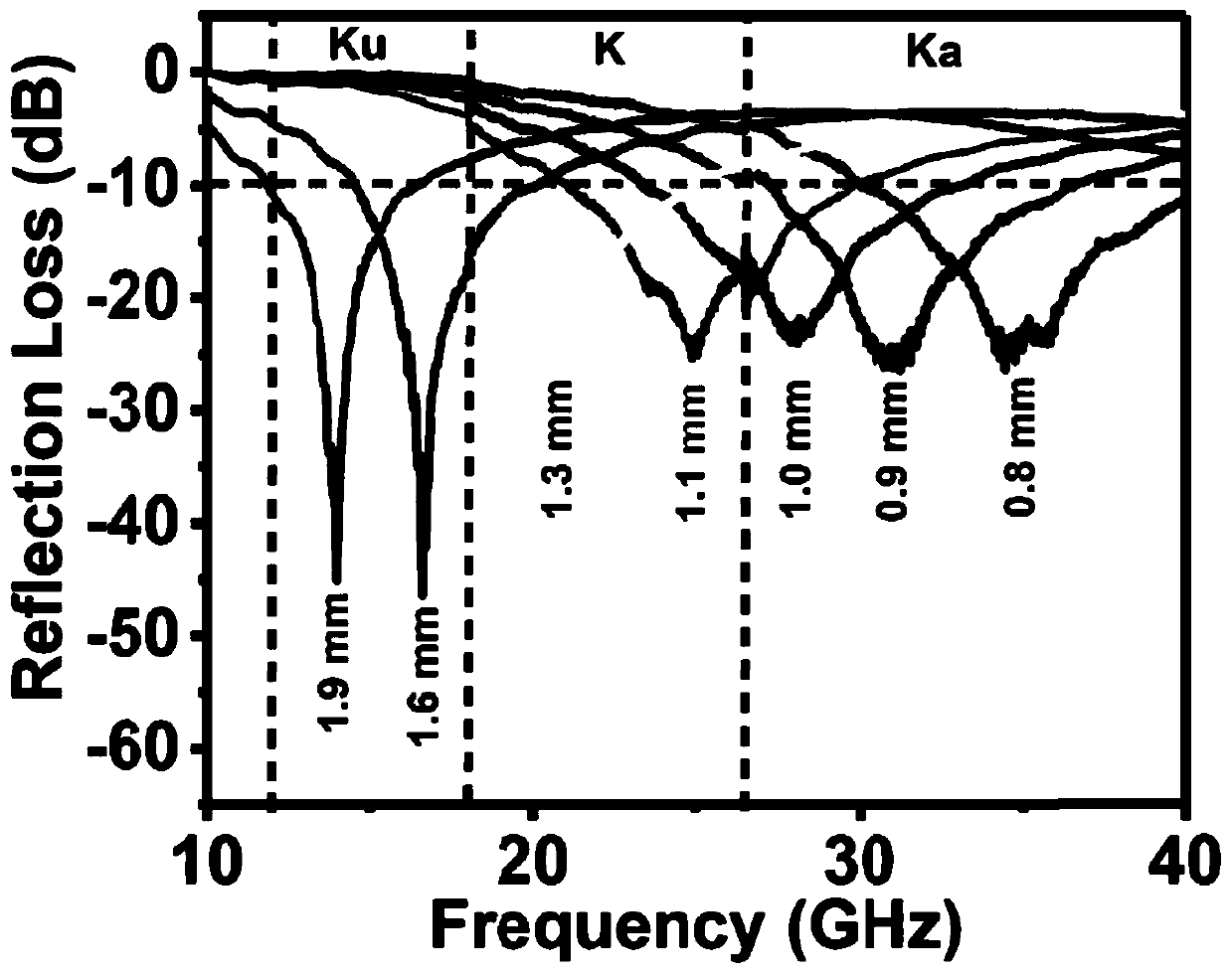

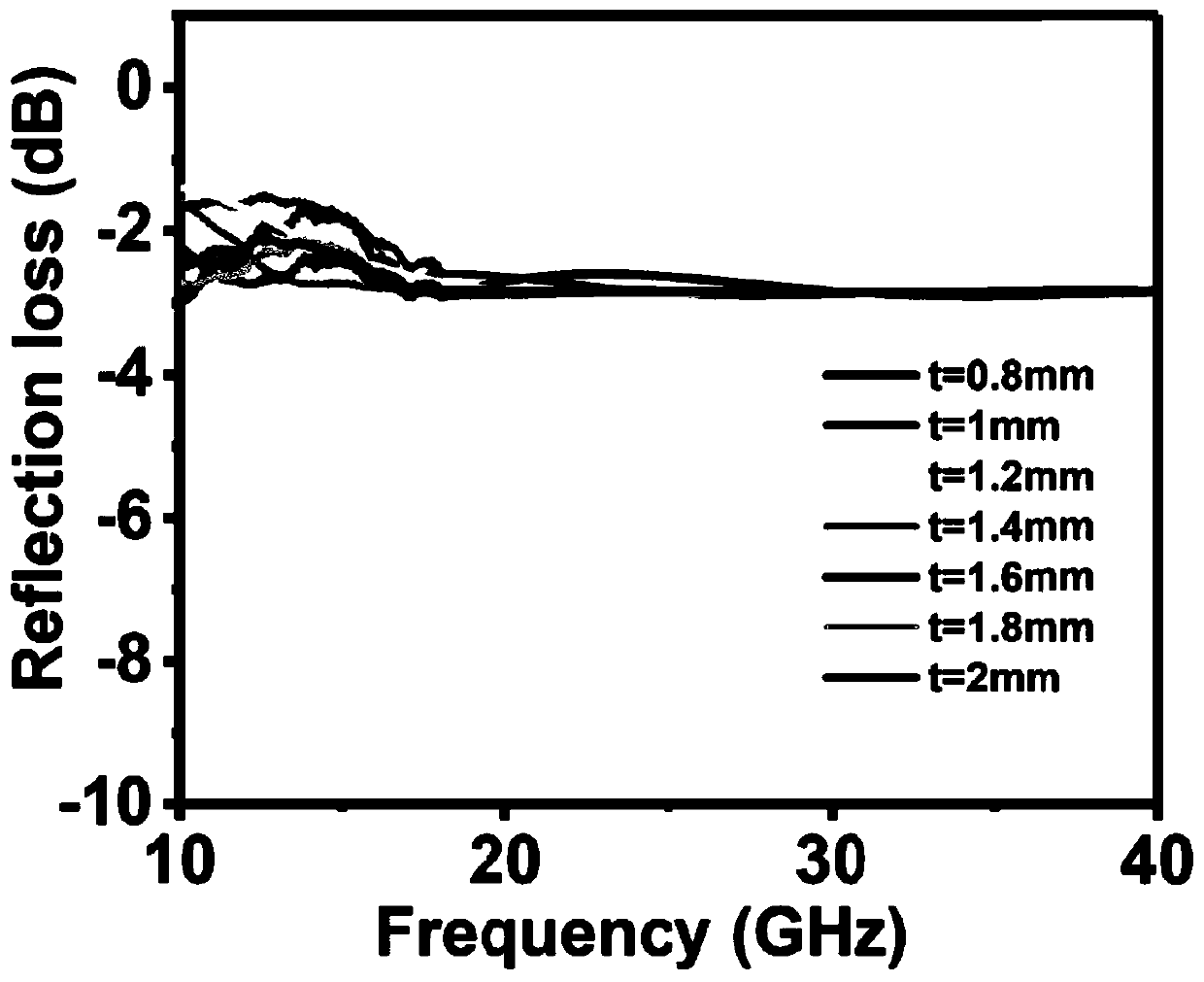

Image

Examples

Embodiment 1

[0032] (1) Preparation of precursor

[0033] First, at room temperature, 5 g of copper nitrate trihydrate was dissolved in 60 mL of deionized water for ultrasonication, and 1.36 g of trimesic acid was dissolved in 60 mL of ethanol for ultrasonication to obtain copper nitrate trihydrate aqueous solution and trimesic acid ethanol solution respectively. Then, under the condition of electromagnetic stirring, the copper nitrate trihydrate aqueous solution was dripped into the trimesic acid ethanol solution dropwise, and then 4mL DMF was dropped dropwise to obtain a mixed solution, and after stirring for 10min, the mixed solution was poured into a stainless steel high-pressure reaction kettle , carry out solvothermal synthesis, and react at 80°C for 20h; finally, the product obtained from the reaction is washed with methanol for 3 times, centrifuged and placed in a vacuum drying oven and dried at 120°C for 12h to obtain copper trimesate (HKUST-1( Cu)).

[0034] (2) Catalytic carbon...

Embodiment 2

[0040] (1) Preparation of precursor

[0041] First, at room temperature, 5 g of copper nitrate trihydrate was dissolved in 60 mL of deionized water for ultrasonication, and 1.36 g of trimesic acid was dissolved in 60 mL of ethanol for ultrasonication to obtain copper nitrate trihydrate aqueous solution and trimesic acid ethanol solution respectively. Then, under the condition of electromagnetic stirring, the copper nitrate trihydrate aqueous solution was dropped dropwise into the trimesic acid ethanol solution, and then 4mL DMF was dropped dropwise to obtain a mixed solution, and after stirring for 10min, the mixed solution was poured into a stainless steel high-pressure reaction kettle , carried out hydrothermal synthesis, and reacted at 80°C for 20h; finally, the reaction product was washed with methanol for 3 times, centrifuged and placed in a vacuum drying oven to dry at 120°C for 12h to obtain trimesic acid copper (HKUST-1 (Cu)).

[0042] (2) Catalytic carbonization

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com