Double-component solvent-free damping coating and its preparation method

A damping coating, solvent-free technology, applied in the field of coatings, can solve the problems of wide damping wet area, low strength of the constrained layer, good corrosion resistance, etc., and achieve the effect of easy construction and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

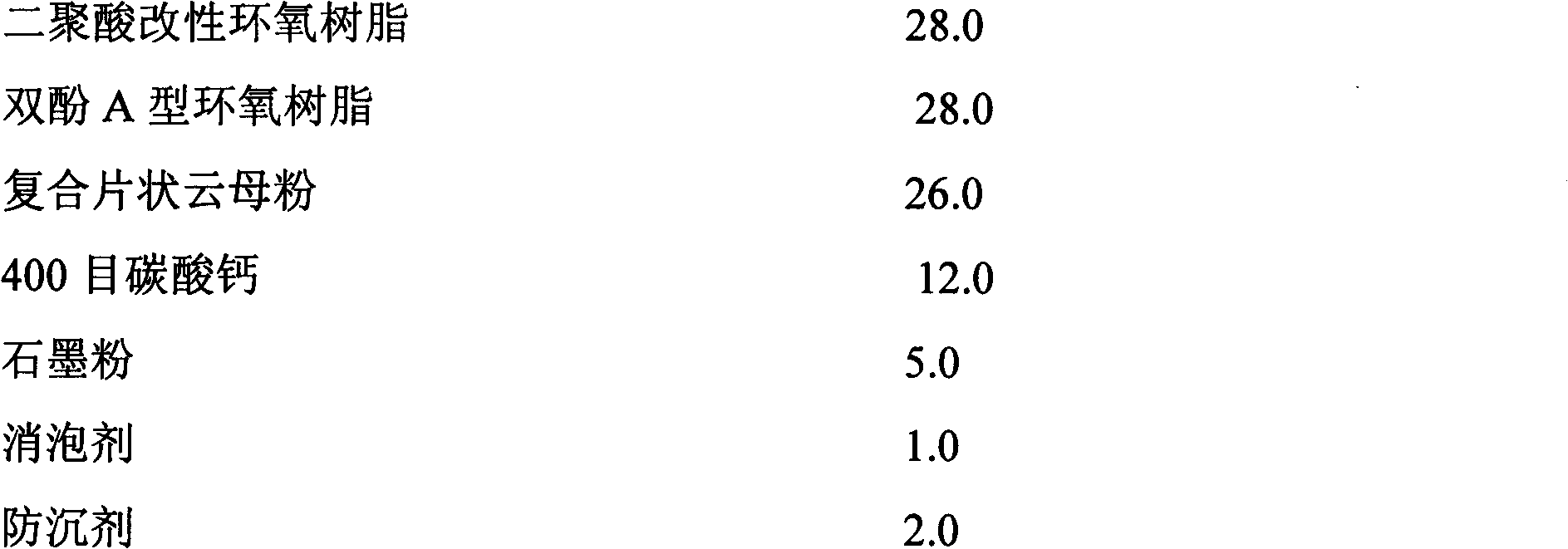

[0034] Paint material is produced in following parts by weight ratio:

[0035]

[0036] The specific steps are as follows: Stir and mix 28.0 parts of dimer acid modified epoxy resin and 28.0 parts of bisphenol A epoxy resin evenly, add 1 part of defoamer, continue to stir evenly, mix 200 mesh and 325 mesh flake mica powder according to After mixing evenly in a ratio of 1:1.5, add 26 parts to the above resin mixture, add 12.0 parts of 400 mesh calcium carbonate, 5.0 parts of graphite powder and 2.0 parts of dustproof agent in sequence, stir evenly, and grind twice with a three-roller machine. When checking that the viscosity reaches 5mm without sagging, the solvent-free damping paint can be obtained.

[0037] Produce curing agent in the following proportions:

[0038] Polyamide adduct curing agent 75.0

[0039] 400 mesh talcum powder 25.0

[0040] The specific steps are as follows: add 75.0 parts of the polyamide adduct to 25.0 parts of 400-mesh talcum powder under stirri...

Embodiment 2~4

[0043] The paint composition is as shown in Table 2:

[0044] Table 2 Embodiment 2~4 paint composition

[0045] raw material name

Example 2

Example 3

Example 4

Polyether modified epoxy resin

18.0

-

-

Rubber Modified Epoxy Resin

5.0

10.0

-

Dimer Acid Modified Epoxy Resin

-

15.0

-

Polyurethane Modified Epoxy Resin

28.0

Bisphenol A epoxy resin

30.0

25.0

23.0

Composite mica powder

26.0

22.0

26.0

16.0

18.5

16.5

graphite powder

2.0

7.0

5.0

1.5

1.0

1.0

Anti-dust agent

1.5

1.5

1.5

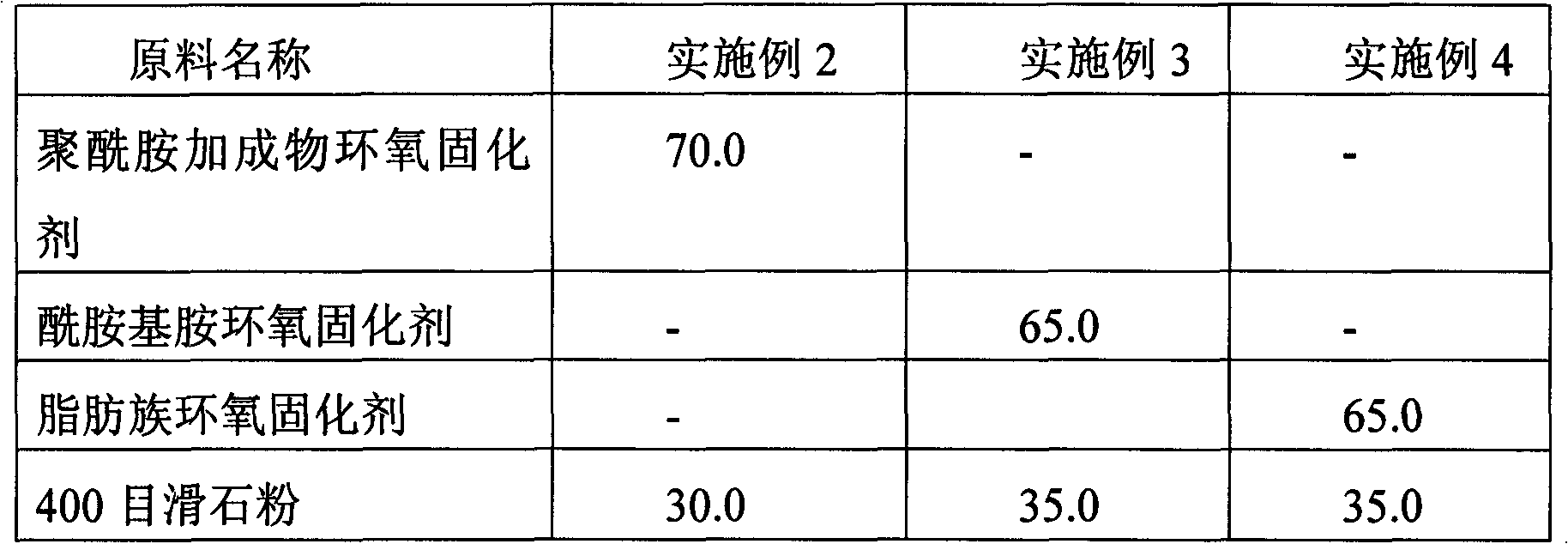

[0046] The composition ratio of curing agent is as follows

[0047]

[0048] The specific operation steps of paint material and curing agent are the same as in Example 1.

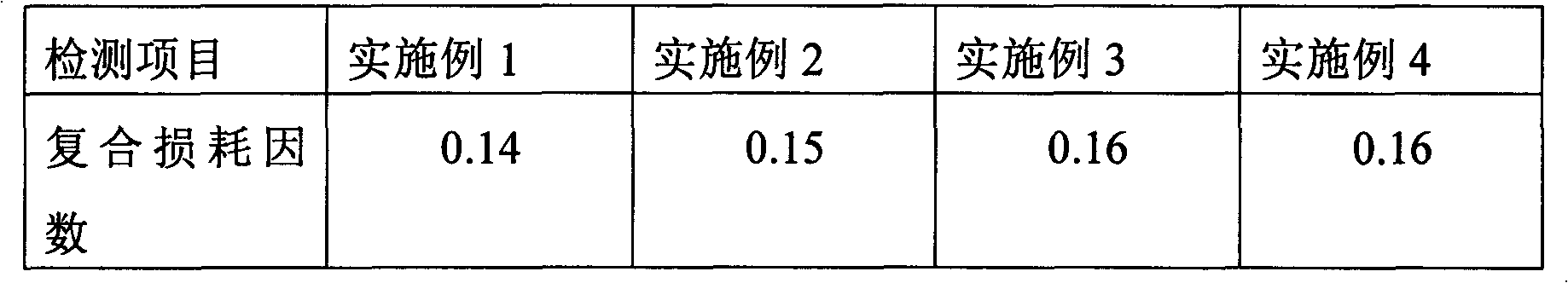

[0049] Examples 2-4 were tested, and the corresponding test ...

Embodiment 5

[0054] A method for preparing a two-component solvent-free damping coating, the method comprising the following steps:

[0055] 1) Preparation of paint

[0056] Stir and mix 15 parts by weight of ether-modified epoxy resin and 30 parts by weight of bisphenol A epoxy resin with an epoxy equivalent of 180, add a commercially available defoamer, continue to stir evenly, and then add 200 mesh and 325 30 parts by weight of composite flaky mica, 10 parts by weight of 400 mesh calcium carbonate, 2 parts by weight of graphite powder, 0.5 parts by weight of commercially available defoaming agent and commercially available dustproof agent 1 part by weight, stir evenly, grind twice with a three-roller machine, check that the viscosity reaches 5mm without sagging, and the solvent-free damping paint can be obtained;

[0057] 2) Preparation of curing agent

[0058] Add 80 parts by weight of the polyamide adduct to 30 parts by weight of talcum powder under stirring, and continue stirring f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com