Soluble microneedle patch used for skin whitening and preparation method thereof

A soluble, microneedle patch technology, applied in the field of skin care products, can solve the problems of piercing the stratum corneum, poor mechanical strength of soluble microneedles, etc., and achieve the effects of lightening pigmentation, favorable for microneedle molding, and good mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

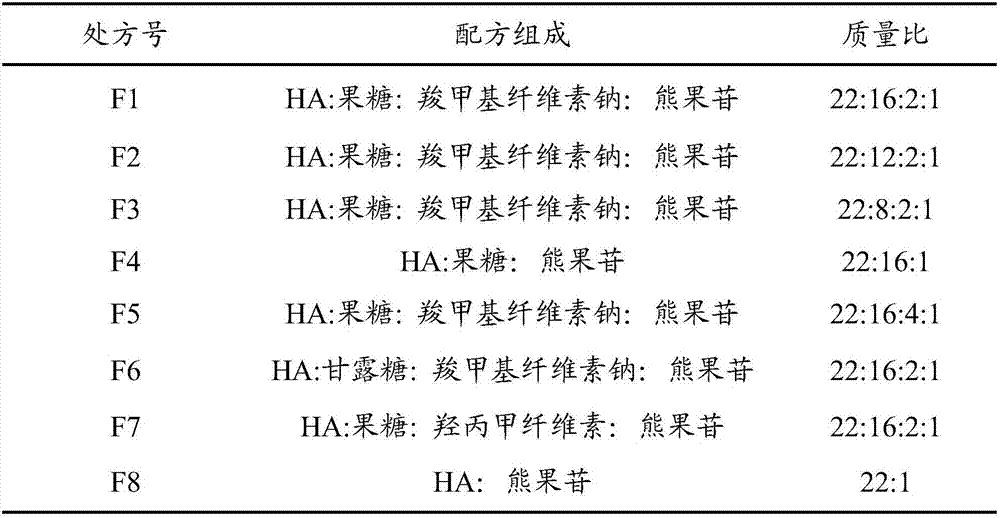

[0047] Dissolvable microneedle patches for whitening prepared with different prescriptions, the formulations of each raw material are shown in Table 1:

[0048] The raw material formula of table 1 dissolvable microneedle patch

[0049]

[0050] Note: HA refers to hyaluronic acid with a molecular weight of 2000kDa.

[0051] The preparation method is as follows:

[0052]According to the raw materials and their proportions shown in Table 1, weigh an appropriate amount of each raw material and place it in a 10ml centrifuge tube, use purified water 2.5 times the total mass of raw materials as a solvent, vortex to mix and dissolve, and prepare 8 kinds of needle tip solutions according to the prescription in Table 1. . Use a syringe to draw the needle tip liquid into the microneedle mold, inject 500 μl of the needle tip liquid into each piece, spread it flat, and centrifuge it in a refrigerated centrifuge (at a temperature of 4°C) at 3000 rpm for 2 minutes, absorb the excess nee...

Embodiment 2

[0054] The hardness and ductility of the 8 whitening dissolvable microneedle patches prepared in Example 1 were tested.

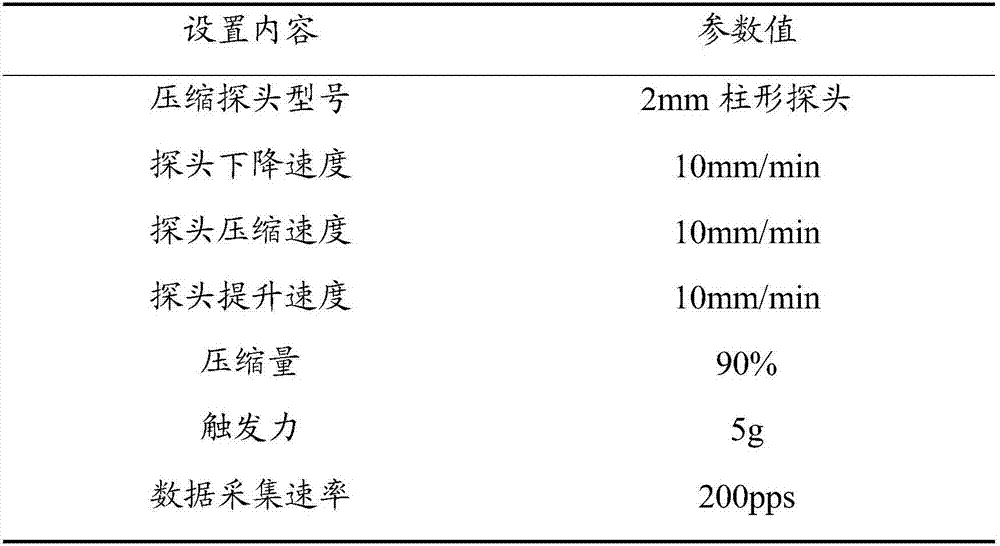

[0055] Place the needle tip of the microneedle patch upward on the horizontal test platform, pass through the P / 6 flat-head stainless steel cylindrical probe, at a stable speed of 0.1mm / sec, with an excitation force of 0.05N, apply an axial vertical force, and set the measurement parameters As in Table 2. The analyzer records the mechanical changes during the probe contact with the needle tip until reaching the preset height (microneedle height 400 μm).

[0056] Table 2 Test parameters

[0057]

[0058] After the test is completed, take out the tested microneedle samples on the stage, and use a microscope to observe the local morphology changes of the microneedles after the force applied by the texture analyzer probe.

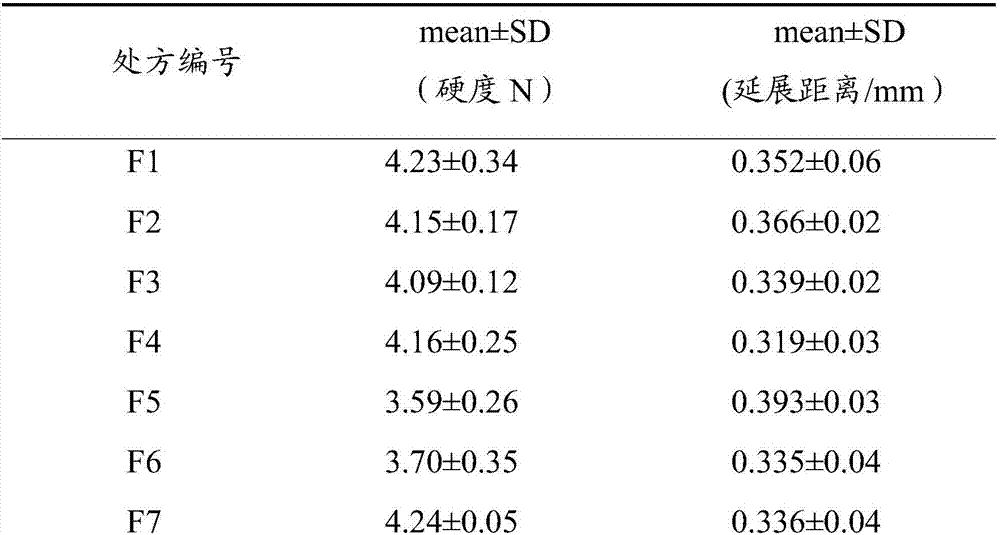

[0059] Table 3 shows the results of testing the hardness and ductility of microneedles prepared by different formulations using textur...

Embodiment 3

[0071] The solubility determination of embodiment 3 dissolvable microneedle patch

[0072] Precisely weigh gelatin of different qualities, purified water, and sucrose according to the proportions in Table 4, place in a 50ml centrifuge tube, dissolve overnight in a water bath at 90°C, centrifuge, degas, quickly transfer to a transparent petri dish, cool, and solidify into gelatin sucrose gels with different water contents.

[0073] Table 4 Gelatin Gel Composition

[0074]

[0075] The 8 kinds of soluble microneedle patches prepared in Example 1 were inserted into the surface of the gel along the edge of the petri dish, observed from the side with an electron microscope at different time points, and recorded the dissolution conditions at different time points until no visible microneedles were observed. The needle body was used as the end point of dissolution, and the microneedle was taken out for further observation under a microscope to confirm the dissolution time point. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com