Ultraviolet-cured anti-dazzle hard film and application thereof

A hard coating, ultraviolet light technology, applied in coatings, optics, optical components, etc., can solve the problems of poor clarity, limited scratch resistance and scratch resistance, achieve good compatibility, increase coating Effect of film anti-glare performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

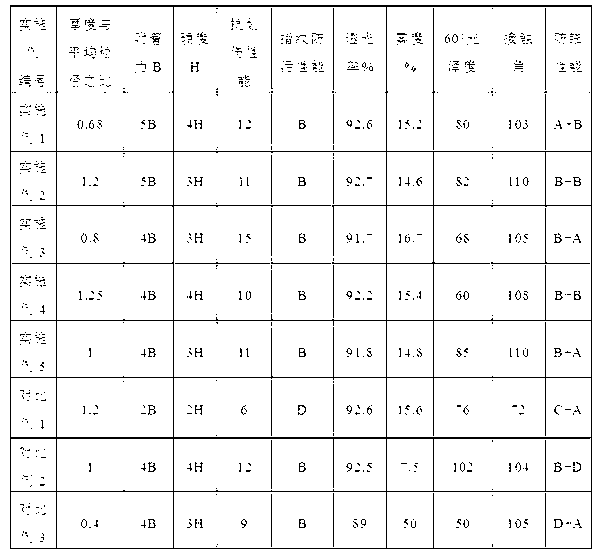

Examples

Embodiment 1

[0055] 20 parts polyurethane acrylate resin

[0056] Silicone modified acrylate resin 10 parts

[0057] Polyester acrylate resin 20 parts

[0058] 10 parts of polymethyl methacrylate resin particles

[0059] Irgacure 184 8 servings

[0060] Toluene: propylene glycol methyl ether = 1: 1 60 parts

[0061]Add 10 parts by weight of polymethyl methacrylate resin particles (average particle size 5 μm, produced by Sekisui Chemical Co., Ltd., brand MB20X-5) to 60 parts by weight of mixed solvent (toluene: propylene glycol methyl ether = 1:1), stir and mix uniform. Add 20 parts by weight of urethane acrylate resin (product of Sartomer, USA, brand CN9006), 10 parts by weight of silicone-modified acrylate resin (product of Sartomer, USA, brand CN990) and 20 parts by weight of polyester acrylic acid Ester resin (product of Sartomer in the United States, brand name CN2281), mix and stir evenly. Add 8 parts by weight of photoinitiator (Irgacure 184), 1.5 parts by weight of leveling ag...

Embodiment 2

[0064] 20 parts polyurethane acrylate resin

[0065] Silicone modified acrylate resin 20 parts

[0066] Polyester acrylate resin 10 parts

[0067] 15 parts of polystyrene resin particles

[0068] Dipentaerythritol hexaacrylate DPHA 20 parts

[0069] Darocur1173 12 servings

[0070] Propanol 40 parts.

[0071] Add 15 parts by weight of polystyrene resin particles (average particle size 6 μm, manufactured by Sekisui Kasei Co., brand SBX-6) to 40 parts by weight of mixed solvent (toluene:propylene glycol methyl ether = 1:1), stir and mix evenly. Add 20 parts by weight of urethane acrylate resin (product of Sartomer, USA, brand CN9013), 20 parts by weight of silicone-modified acrylate resin (product of Sartomer, USA, brand CN990) and 10 parts by weight of polyester acrylic acid Ester resin (product of Sartomer in the United States, the brand is CN2295), mixed and stirred evenly. Add 12 parts by weight of photoinitiator (Darocur1173), 2 parts by weight of leveling agent (EFKA...

Embodiment 3

[0074] 20 parts polyurethane acrylate resin

[0075] Silicone modified acrylate resin 10 parts

[0076] Polyester acrylate resin 10 parts

[0077] Trimethylolpropane Triacrylate TMPTA 20 parts

[0078] 20 parts of polymethyl methacrylate resin particles

[0079] Irgacure369: Irgacure907=1:1 10 servings

[0080] 50 parts of ethyl acetate.

[0081] Add 20 parts by weight of polymethyl methacrylate resin particles (average particle size 10 μm, produced by Sekisui Kasei Co., brand MB20X-10) to 50 parts by weight of solvent ethyl acetate, and stir to mix evenly. Add 20 parts by weight of polyurethane acrylate resin (Taiwan Changxing Chemical Company, grade 6145-100), 10 parts by weight of silicone modified acrylate resin (Taiwan Changxing Chemical Company, grade 6225) and 10 parts by weight of polyester acrylate resin (Taiwan Changxing Chemical Company, grade 6311-100), and 20 parts by weight of trimethylolpropane triacrylate TMPTA, stirred and mixed evenly. Add 10 parts by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com