Electrothermic purifying filter element for treating high-air-quantity VOCs (volatile organic chemicals) waste gas

An exhaust gas treatment and electrothermal technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of not meeting the requirements of large air volume VOCs exhaust gas purification, existing safety, large wind resistance, etc., to achieve small equipment, The effect of compact packing and reducing wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

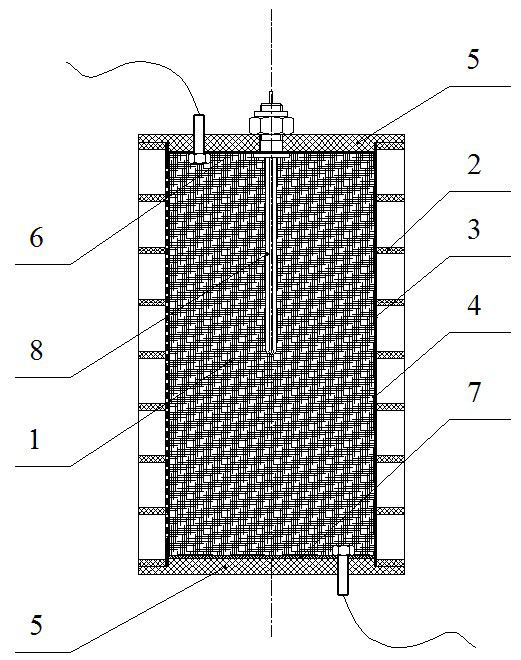

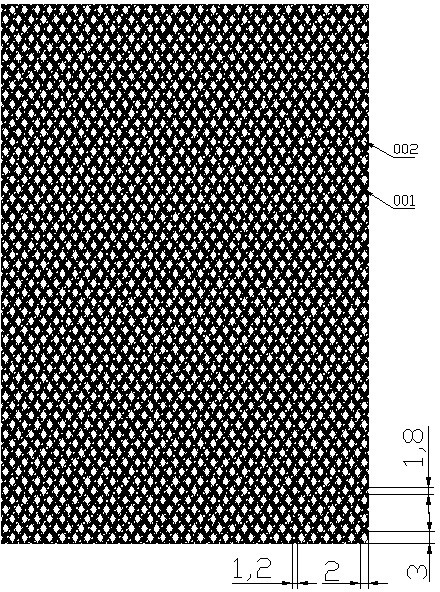

[0026] The electrothermal purification filter element used for the treatment of large air volume VOCs exhaust gas in this embodiment is as follows: figure 1 As shown, the appearance of the electrothermal purification filter element is a hexahedron structure parallel to the air inlet surface and the air outlet surface, including the enclosure structure and the adsorption bed 1 filled inside. The enclosure structure is fixed by the air inlet surface, the air outlet surface and other , sealing, and protective protection plate 5, the air inlet surface and the air outlet surface are a layer of grille 2, a layer of porous sieve plate 3 and a layer of insulating screen 4 from the outside to the inside, the guard plate 5, the grille 2 , the porous sieve plate 3 are all made of epoxy resin material, the insulating screen 4 is a glass fiber screen, and the adsorption bed 1 is Figure 3-Figure 7 The activated carbon mesh cloth and activated carbon fiber cloth (felt) shown are formed by p...

Embodiment 2

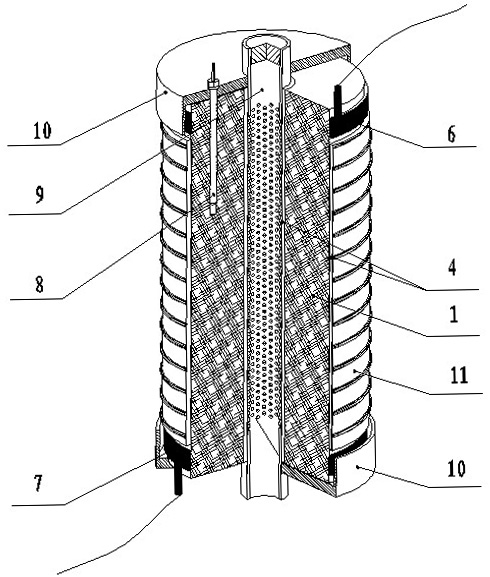

[0040] The electrothermal purification filter element used for the treatment of large air volume VOCs exhaust gas in this embodiment is as follows: figure 2 As shown, the appearance of the electrothermal purification filter element is a cylinder, including the enclosure structure and the adsorption bed 1 filled inside. The enclosure structure is composed of an inner cylinder 9, an end cover 10 and an outer cylinder. The inner cylinder 9 and the outer cylinder The cylinder body is the air inlet surface and the air outlet surface respectively. The inner cylinder body 9 is a hollow porous cylinder with one end closed and made of epoxy resin material, on which it is tightly wound in a manner corresponding to the hole layout, such as Figure 3-Figure 7 The shown activated carbon mesh cloth and activated carbon fiber cloth (felt) form an adsorption bed 1, and the outer cylinder is surrounded by multi-layer insulating screens 4 and fastened by clamps 11 to ensure that the adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com