Wind-power rotary disc type viscous friction water heater

A wind-powered rotation and water heater technology, applied in water heaters, fluid heaters, wind engines, etc., can solve problems such as low heat yield, low water viscosity, and affecting heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

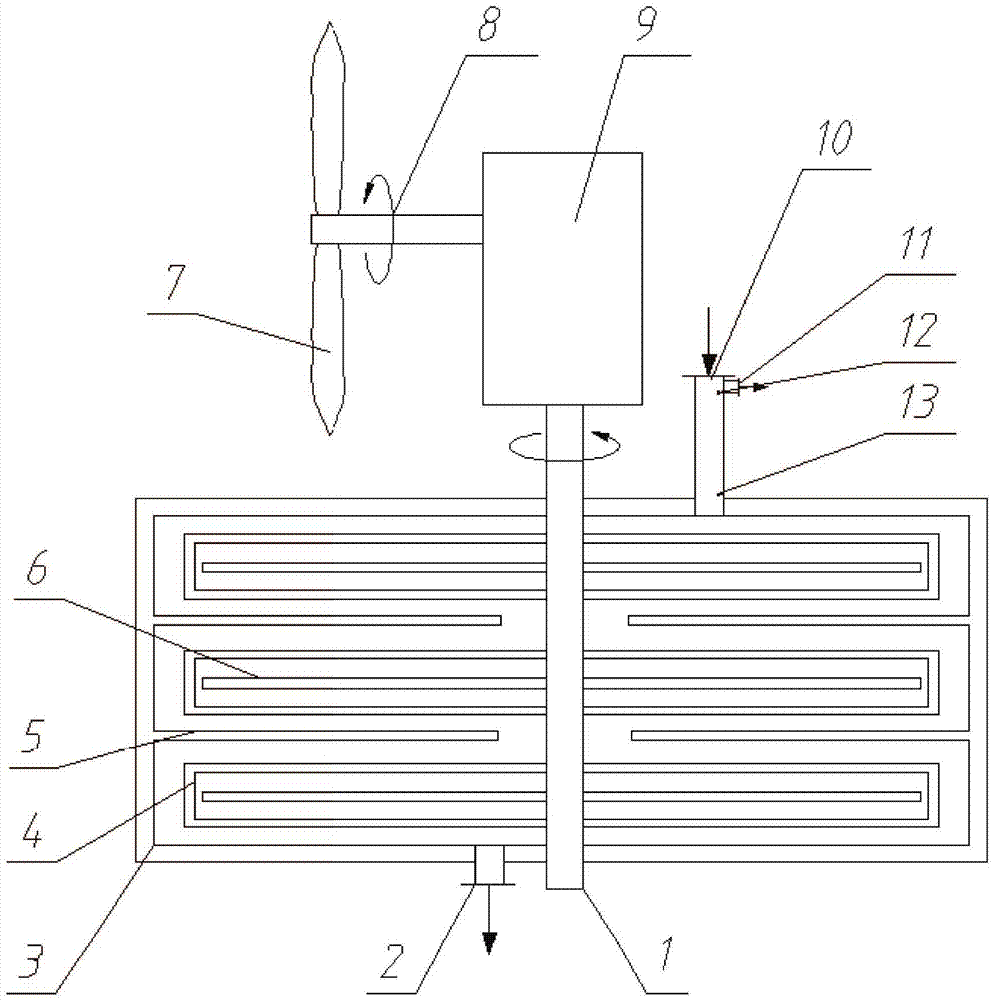

[0023] see figure 1 . figure 1 It is a structural schematic diagram of the wind-driven rotating disk type viscous friction water heater according to the present invention, including: a friction water heater 3, and the friction water heater 3 includes: a disc rotating shaft 1, on which a plurality of spaced friction water heaters are installed. Disc 6, the friction disc 6 is placed in the heating chamber 4 fixed on the inner wall of the friction water heater 3, the heating chamber 4 is in dynamic and static connection with the rotating shaft, and a seal is arranged between the two; baffles 5. The baffle plate 5 is installed on the inner wall of the friction water heater 3 and is located outside the outer wall of the heating chamber 4. The space formed by the three is a water flow channel; the cold water inlet 10 and the hot water outlet 2, the hot water The water outlet 2 is located at the bottom of the friction water heater 3, the cold water inlet 10 is located at the top of ...

Embodiment 2

[0029] The wind-powered rotary disc viscous friction water heater of the present invention can be combined with other forms of new energy such as solar energy, tidal energy, etc., or electric energy and other conventional energy sources to jointly realize the hot water function. Example 1 is exactly the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com