Fault separation technique for chemical production abnormal sub-domain

A technology of fault separation and chemical production, applied in the direction of electrical testing/monitoring, etc., can solve the problems of meaningless detection, inability to separate faults, and inability to determine the cause of faults, etc., achieve practical application and operability, and improve relative accuracy and reliability, technologically advanced results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

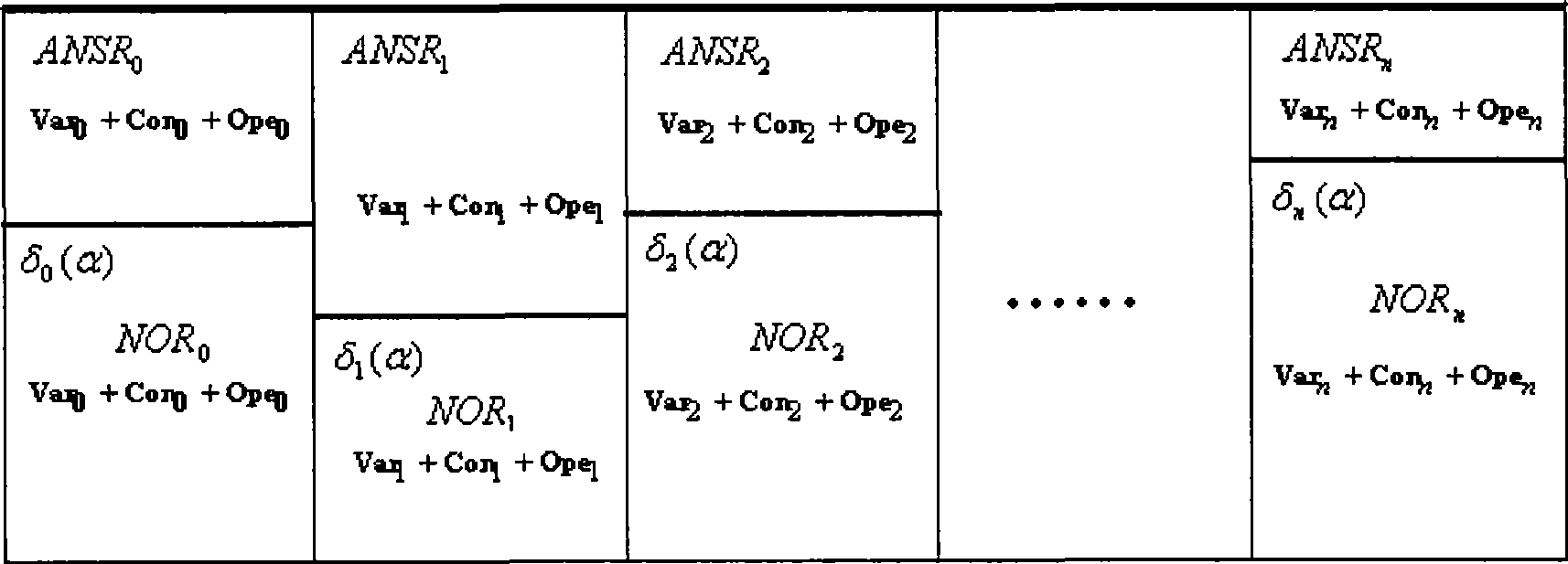

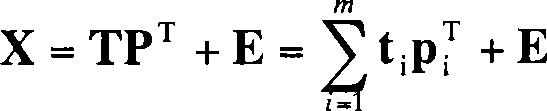

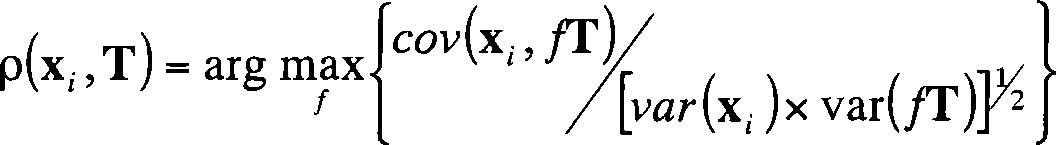

[0012] The present invention first conducts information analysis on all process variables, which can make the information richer and the correlation between the information stronger, and the characterization of the same fault detection is more obvious, and at the same time make the relevant information, especially the fault information related to the principal component more focused. Therefore, the correlation analysis between the process variable and the principal component can classify the variables, and the principal related variable (PRV) is in turn PRV 0 , PRV 1 ,...,PRV n .

[0013] The variable information after classification is all information domains containing faults, and the information among them is both related and overlapping, so the overall variable information domain must be decomposed. The present invention divides it into abnormal subfields, and the others are normal subfields, so that faults can be separated within a certain range.

[0014] The establis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com