Method for testing potential failure risks of antiskid braking control boxes by aid of quick temperature variation

A technology of anti-skid braking and temperature change, applied in the direction of electrical testing/monitoring, etc., can solve the problems of limitations, few introduction of reliability strengthening test equipment, etc., and achieve the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

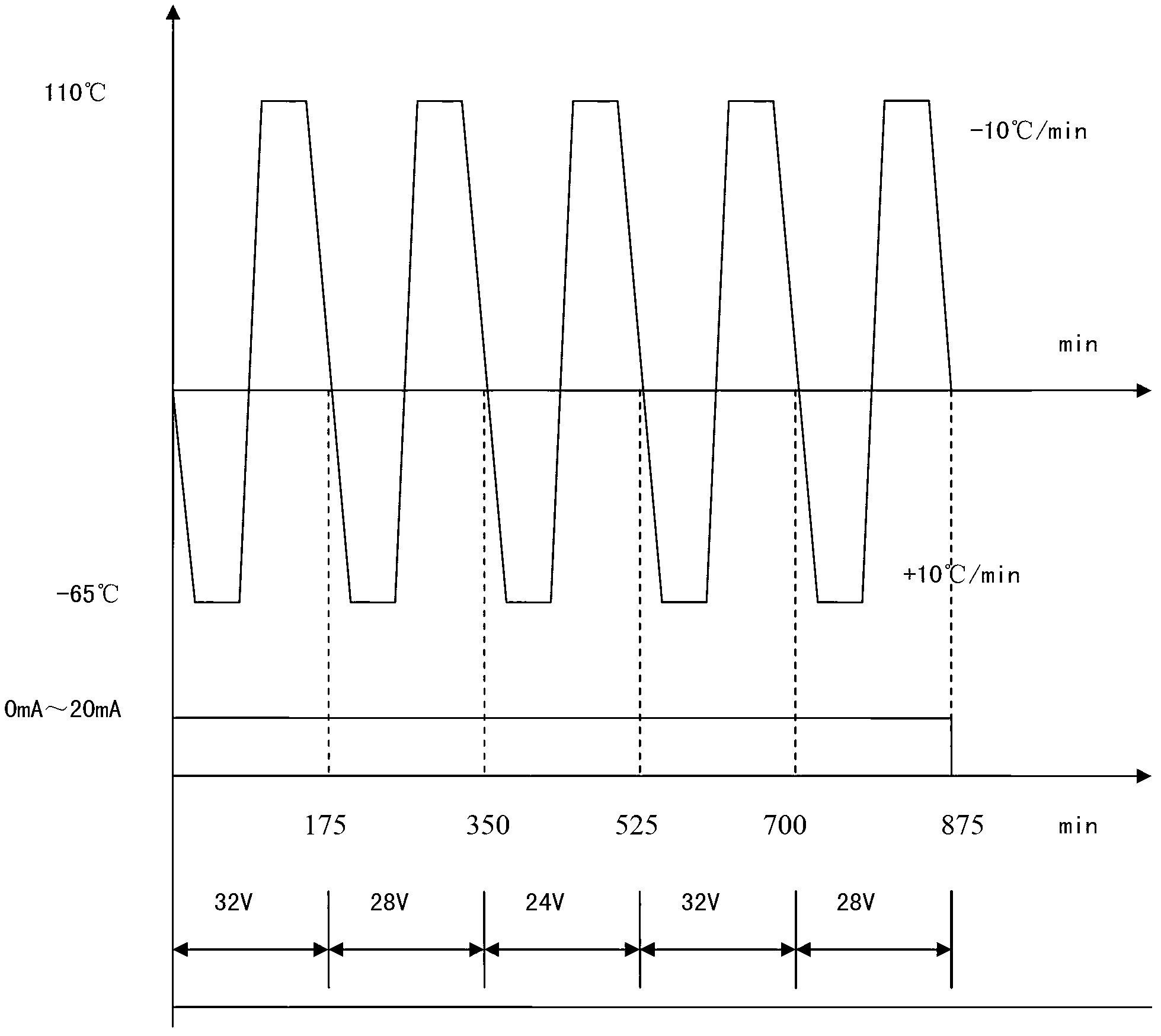

Embodiment 1

[0079] This embodiment is a method for testing the anti-skid brake control box of a certain type of conveyor under the condition of rapid temperature change.

[0080] The specific steps of this embodiment are:

[0081] Step 1. Determine the high temperature value of the rapid temperature change test of the anti-skid brake control box

[0082] A method of applying high-temperature step stress and working stress to the anti-skid brake control box to test the damage limit of the anti-skid brake control box. The high temperature damage limit of the anti-skid brake control box in this embodiment is improved to be greater than 115°C;

[0083] Determine the high temperature value of the rapid temperature change of the comprehensive environmental test box. The high temperature value of the rapid temperature change is 5℃~10℃ lower than the high temperature damage limit. The high temperature value taken in this embodiment is 110℃, which is 5℃ lower than the high temperature damage limit. 110℃ i...

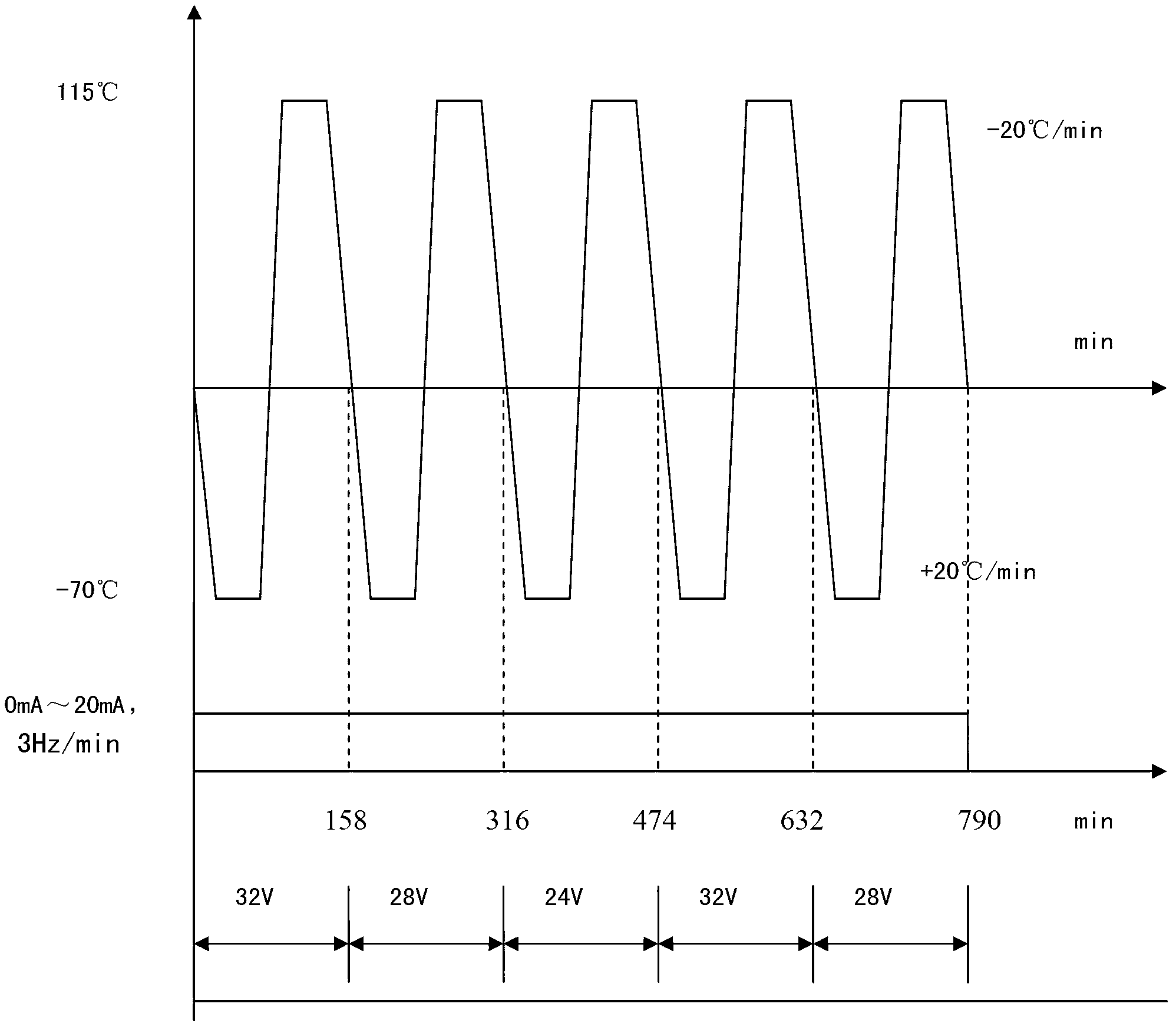

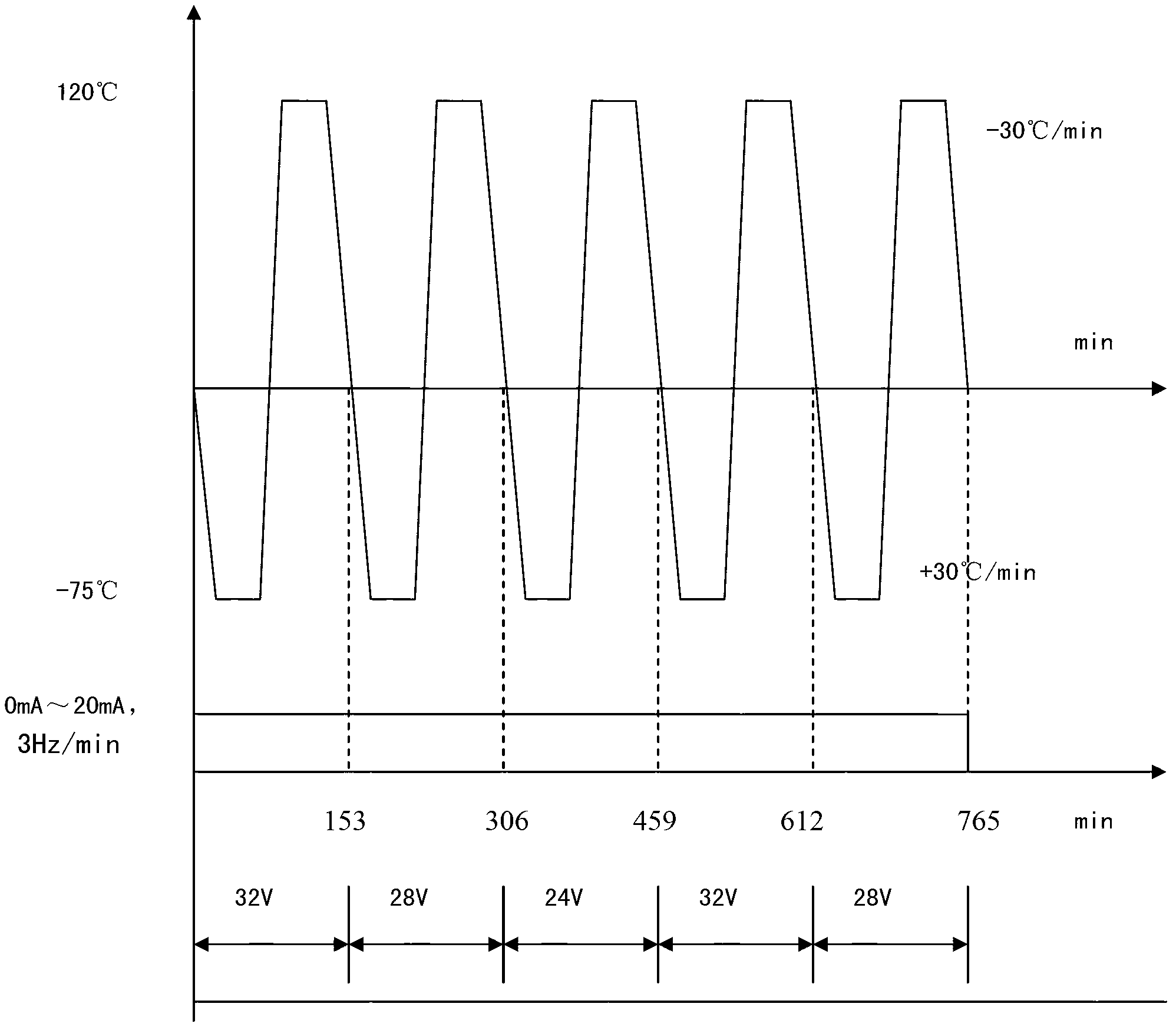

Embodiment 2

[0121] Examples 2 and 3 both include determining the high temperature value of the anti-skid brake control box rapid temperature change test, determining the low temperature value of the anti-skid brake control box rapid temperature change test, determining the rapid temperature change rate value, and determining the anti-skid brake during the test. The operating current applied by the control box, determine the temperature retention time of the anti-skid brake control box under high and low temperature conditions, develop a rapid temperature change test profile, test according to the rapid temperature change test profile, and test and verify the improved antiskid brake control box For each step, the specific process is the same as that of Example 1, and the difference is that the test data in Example 2 and Example 3 are different from the test data in Example 1, as shown in Table 3.

[0122] The main test data of the 3 examples are summarized in Table 3.

[0123] Table 3 Summary t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com