Rail transit electronic single board enhancement test method

A technology of rail transit and test method, which is applied in the field of rail transit, can solve problems such as shortage, long test time, and high cost, and achieve the effect of ensuring reliability and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

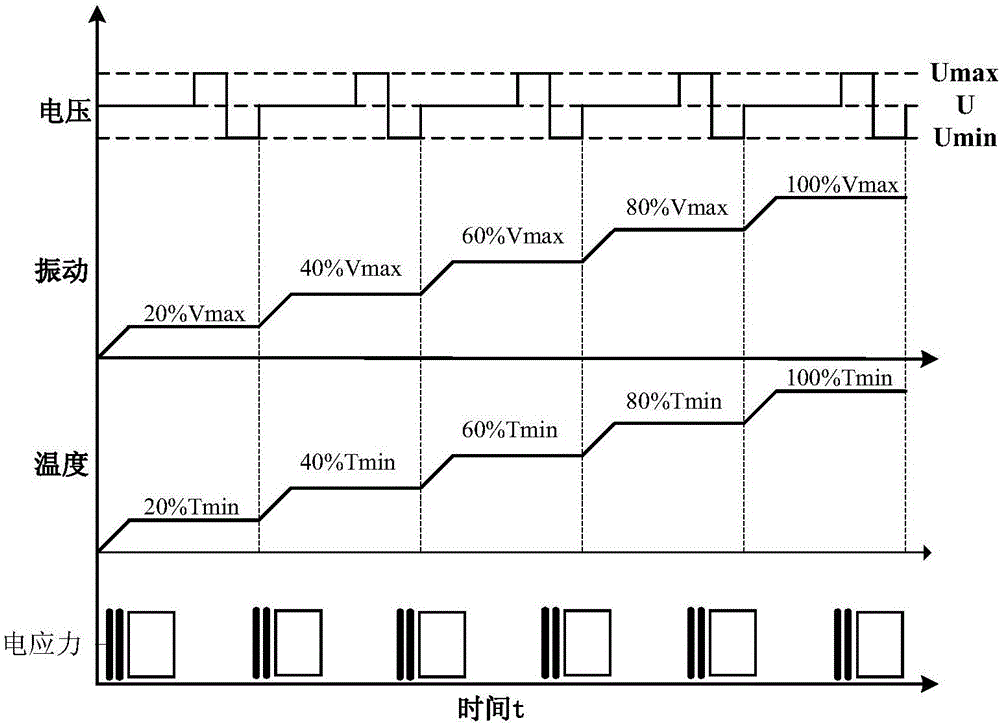

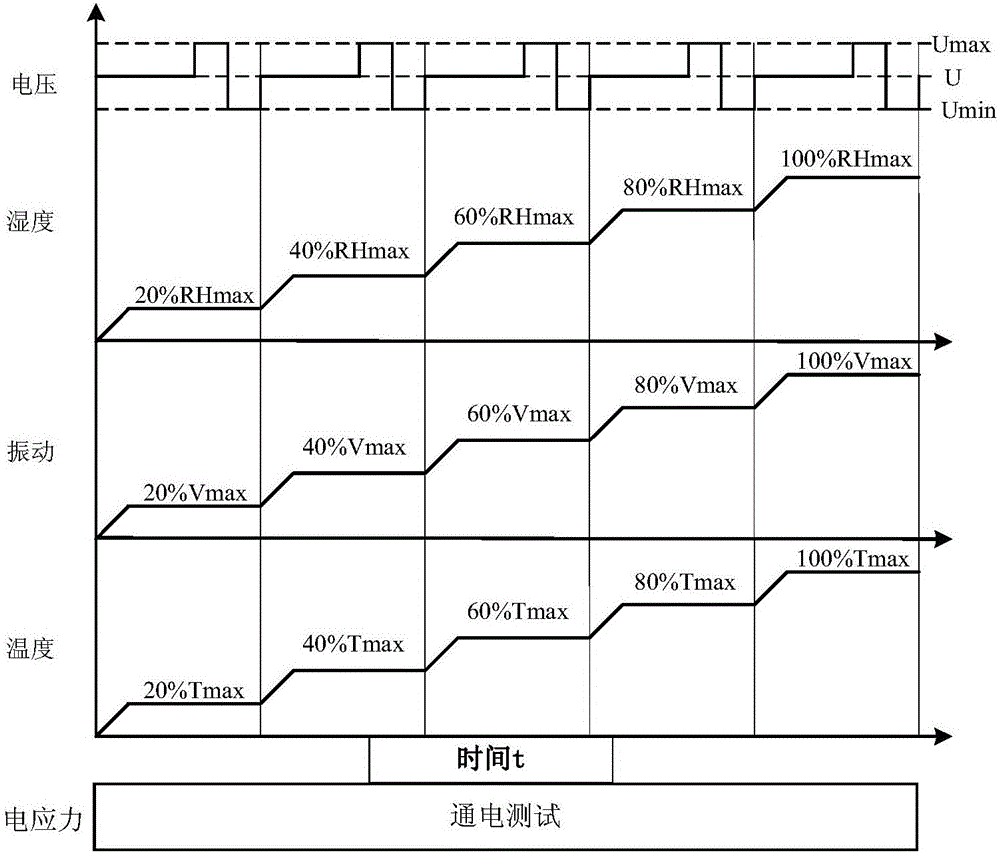

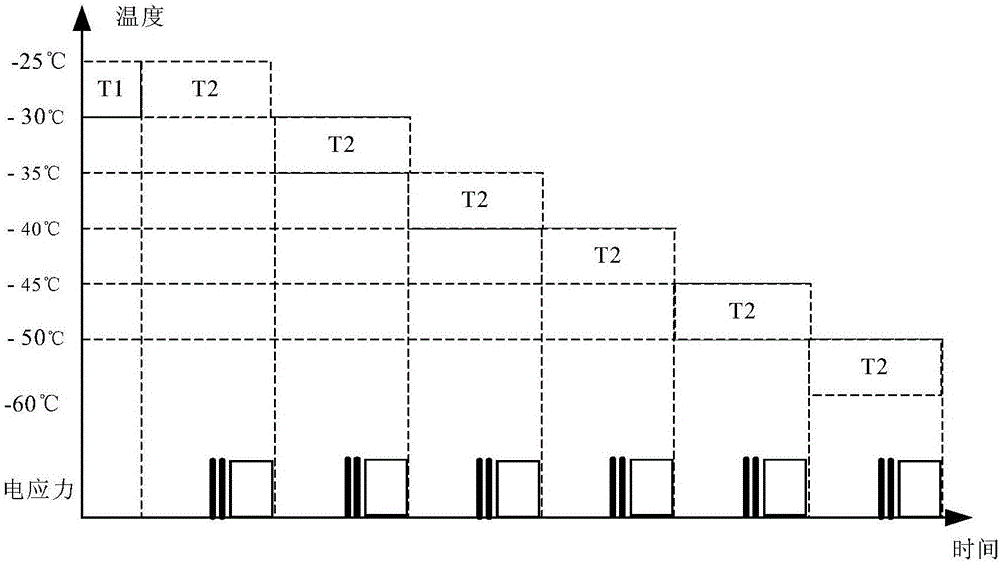

[0032] Such as figure 1 As shown, the rail transit electronic veneer strengthening test method of the present embodiment includes the first comprehensive test combining low temperature and vibration, and specifically includes the following steps:

[0033] S01. First, determine each first comprehensive test point in the first comprehensive test, and each first comprehensive test point has a corresponding temperature value and vibration value;

[0034] S02. When the electronic single board is in a power-on state, maintain the first preset time at each first comprehensive test point, and perform an offline or online test on the electronic single board;

[0035] S03. After completing all the tests at the first comprehensive test point, place the electronic single board under the debugging environment conditions for offline testing.

[0036] The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com