Double-joint loading power servo knife rest power head reliability test bed and test method

A technology of servo tool post and combined loading, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve the problems that the combined loading and spraying of power heads cannot be simulated, and achieve real-time monitoring and closed-loop control And feedback, the effect of high loading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

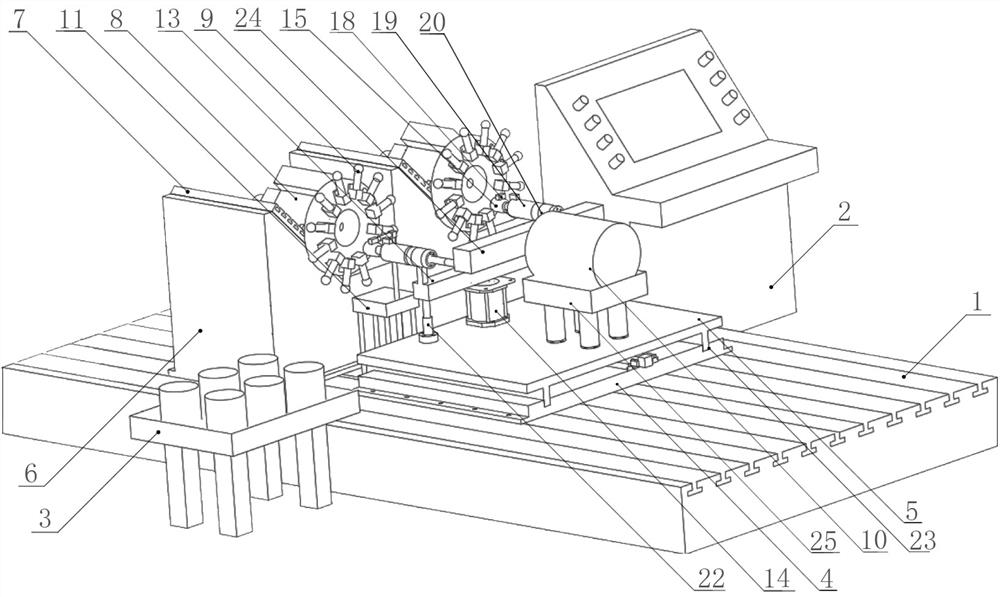

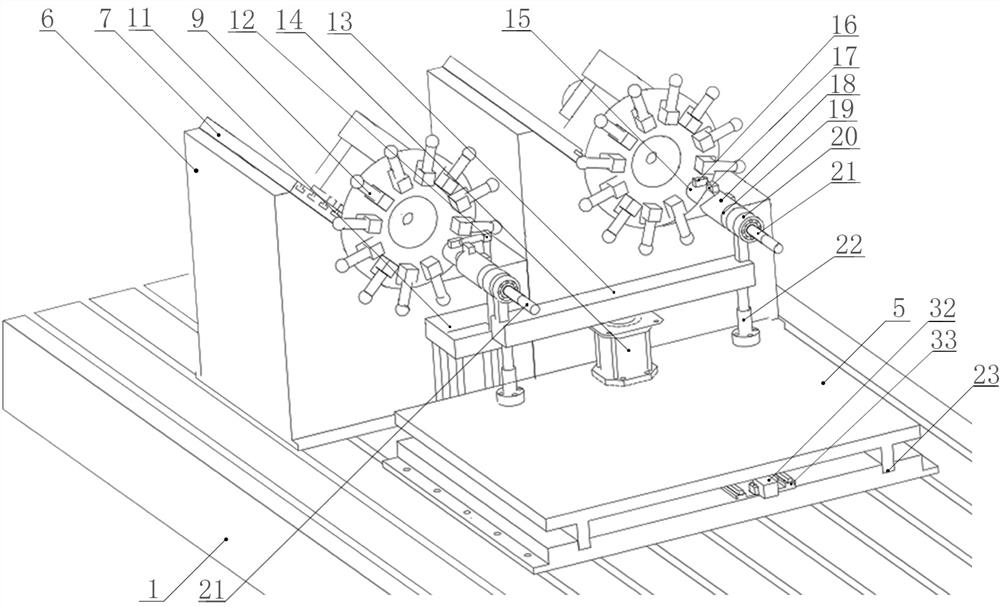

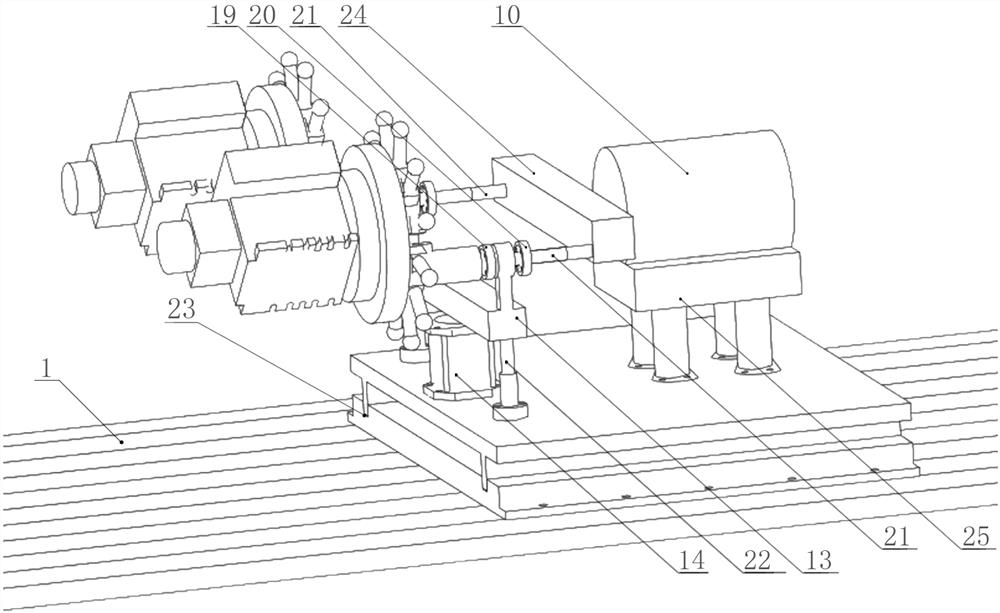

[0069] Example 1 Reliability test bench for dual combined loading power servo tool holder power head

[0070] see Figure 1 to Figure 5 As shown in the figure, the reliability test bench for the power head of the double combined loading power servo tool holder includes: ground level iron 1, the part of the power servo tool holder, the loading part of the power head, the spray system part, the dynamometer part, and the detection control part;

[0071] The horizontal iron 1 is a solid cast iron structure, and the upper surface is provided with T-shaped grooves parallel to each other;

[0072] The power servo tool holder part includes: a power servo tool holder base 6, a power servo tool holder backing plate 7, a power servo tool holder 8, a simulated tool holder 9 and a power head 15;

[0073] The power servo tool rest base 6 adopts an integral casting with a polygonal hollow structure; the bolts are installed in the T-shaped groove of the horizontal iron 1, and the bottom of t...

Embodiment 2

[0101] Example 2 Reliability test method of double combined loading power servo tool holder power head

[0102] The method for testing the reliability of the power head of the double joint loading power servo tool holder according to the present invention adopts the reliability test bench for the power head of the double joint loading power servo tool holder described in Embodiment 1, and provides a power servo tool holder for the tested piece. A set of reliability test methods;

[0103] refer to Image 6 and Figure 7 , the reliability test of the power head of the power servo tool holder with double joint loading mainly includes the indexing test of the power servo tool holder and the joint loading test of the power head. The specific method steps are as follows:

[0104] 1. Indexing test of the dynamic servo tool post

[0105] 1) Keep the temperature of the test environment constant at 20 degrees Celsius, and place the test bench in the test environment for more than 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com