Metal slide fastener and manufacturing technology and metal slide fastener surface gold paint seal treatment machinery

A metal zipper and sealing technology, applied in the pretreatment surface, the device and application of coating liquid on the surface, etc., can solve the problem of heavy chemical corrosion, uneven product surface, no paint leveling, etc., to achieve hardness Good, good processing quality, anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

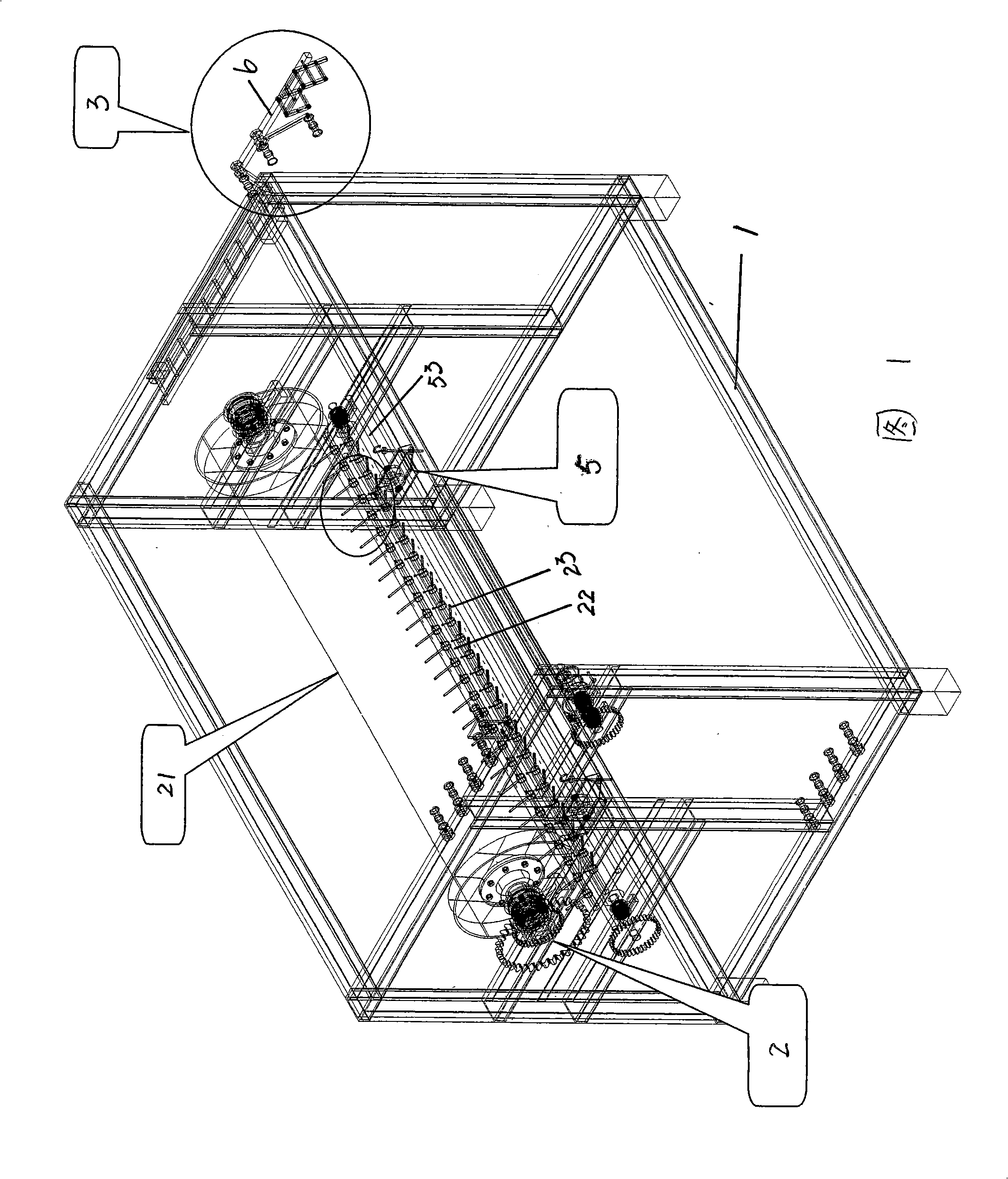

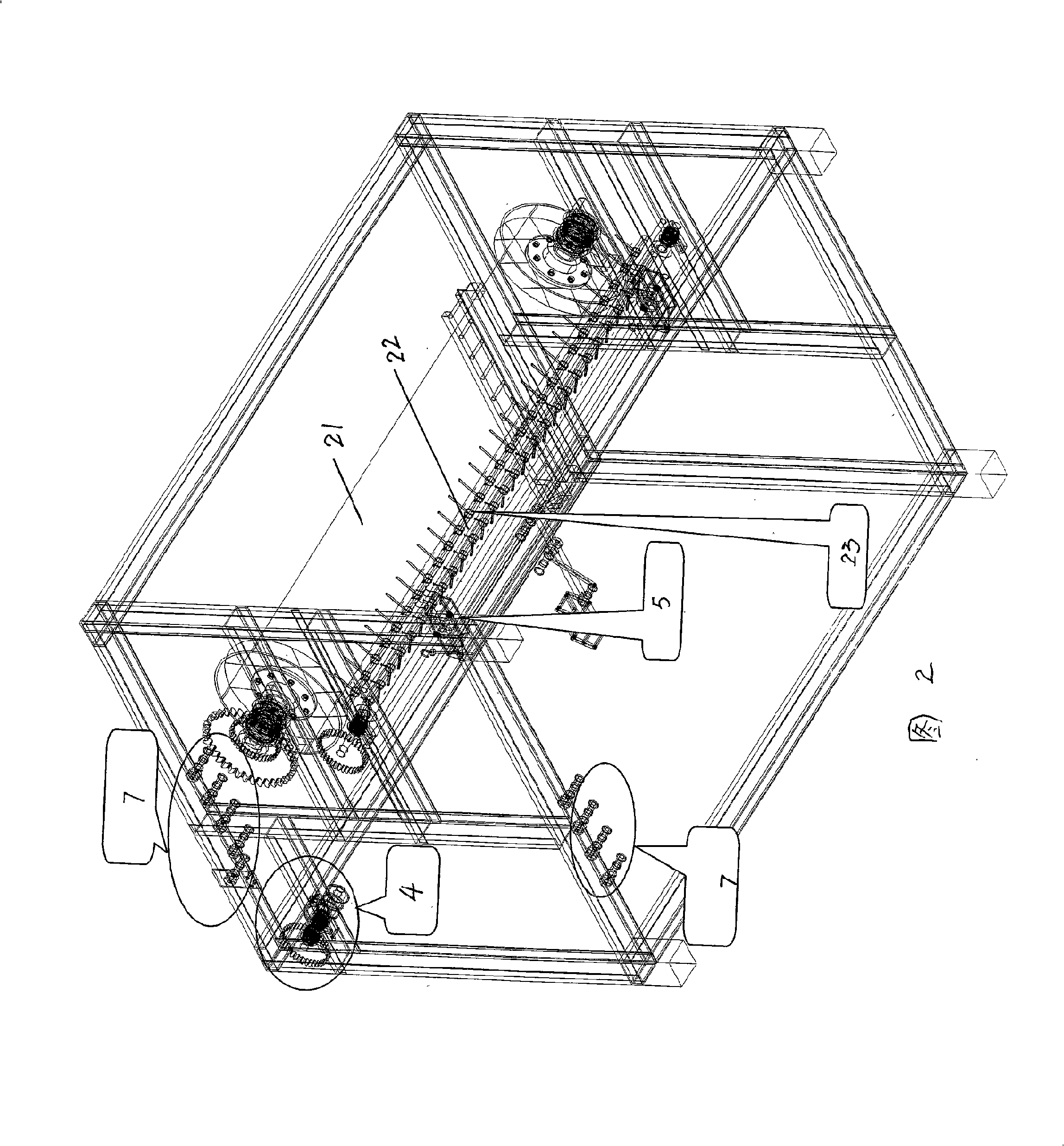

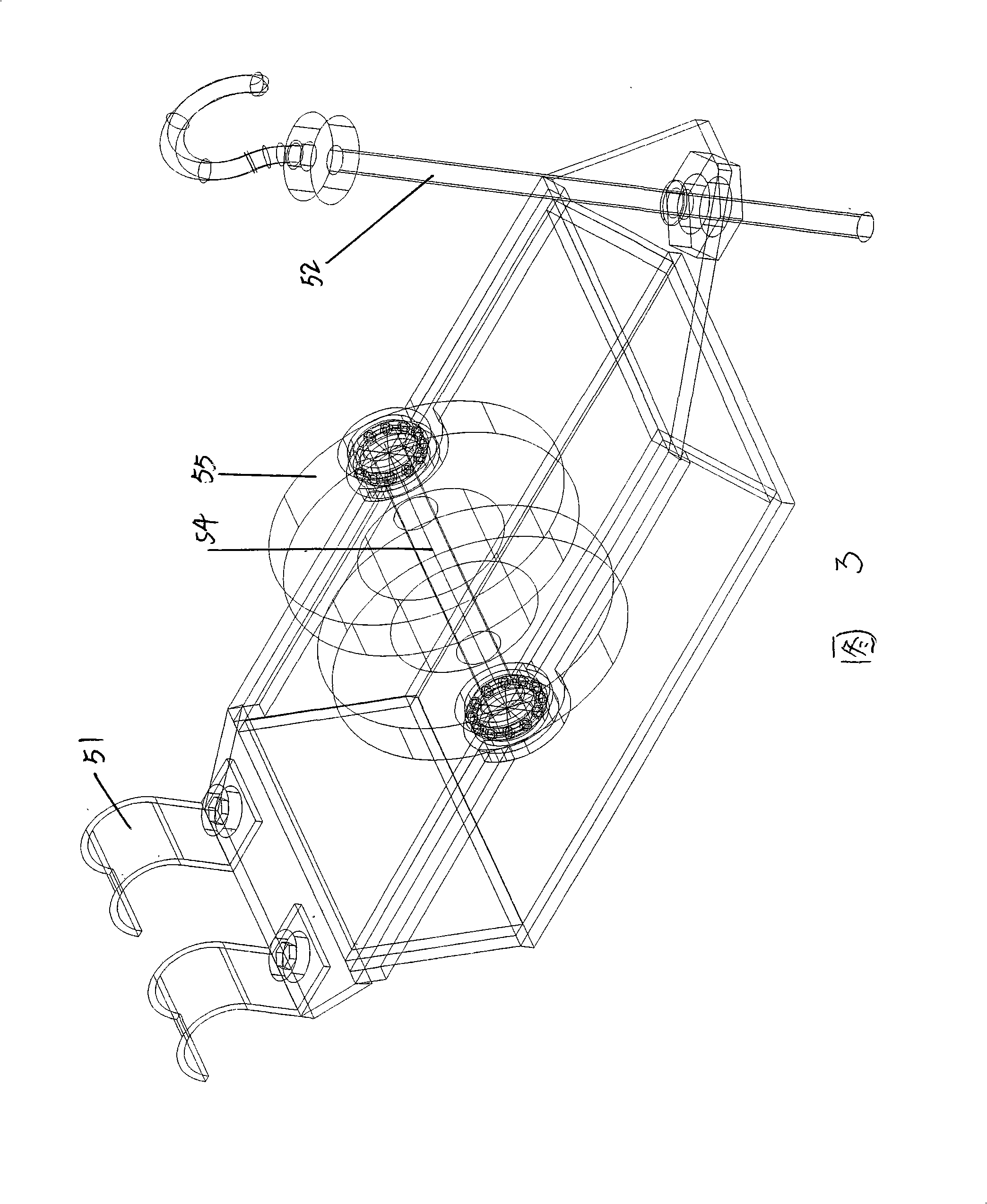

[0014] Embodiment 1, a metal zipper surface gold oil sealing treatment machine, comprising a sealing frame 1, large and small rollers and a transmission device 2 thereof, one end of the top of the sealing frame 1 is equipped with a pulley 3, and the other end is equipped with a pulley 4, The large stainless steel drum 21 and the small stainless steel drum 22 arranged in parallel up and down are all fixed on the corresponding two sides of the closed frame 1 by bearings, the small drum 22 is equipped with sub-belt teeth 23, and the small drum 22 is equipped with two separate belts below. A gold oil box 5 in a trapezoidal structure, the two ends of the gold oil box 5 are respectively hung on the top of the small drum 22 by a hook 51 and an extension spring 52 and are parallel to the small drum 22, and are fixed on two steel pipe supports 53 on both sides of the closed frame , the gold oil box 5 top is provided with a bearing 54, and its two ends are fixed on the both sides of the ...

Embodiment 2

[0017] Embodiment 2, a kind of anti-staining, anti-oxidation, washable metal slide fastener, metal slide fastener surface is covered with one deck gold oil, and this gold oil is made of two-component epoxy varnish, epoxy curing agent, epoxy diluent by weight The ratio is 1:1:2.5 compatibility composition.

[0018] The manufacturing process is: use the metal slide fastener surface gold oil sealing treatment machine described in embodiment 1 to roll and coat gold oil on the surface of the metal slide fastener after oxidation and coloring at room temperature, first preheat the metal slide fastener on large and small rollers, and then coat one side with gold oil Dry it on a roller, then apply gold oil on the second side, dry it, and carry out tension cooling and shaping on the metal zipper coated with gold oil.

Embodiment 3

[0019] Embodiment 3, a kind of anti-staining, anti-oxidation, washable metal zipper, metal zipper surface is covered with one deck gold oil, this gold oil is made of two-component epoxy varnish, epoxy curing agent, epoxy diluent by weight The ratio is 1:1.2:3.5 compatibility composition.

[0020] The manufacturing process refers to Example 2, wherein the gold oil coating on each side adopts two overcoating methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com