Forming method and forming equipment for ternary composite reconstituted tobacco sheets

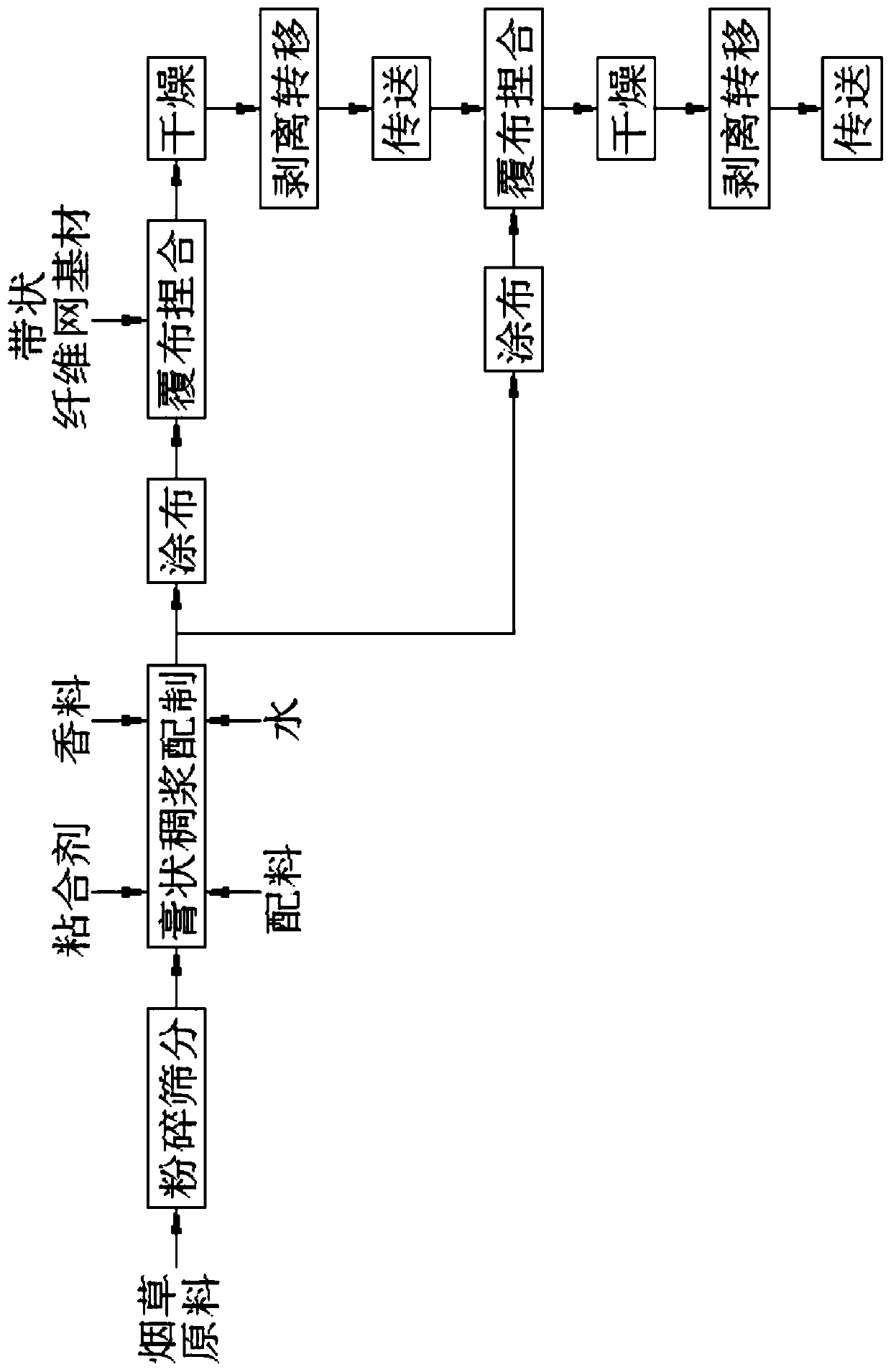

A technology of reconstituted tobacco and ternary compounding, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment, etc. It can solve the problems affecting the taste of reconstituted tobacco sheets, affecting the quality of reconstituted tobacco sheets, the scope of application of back-end processes, and uneven coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

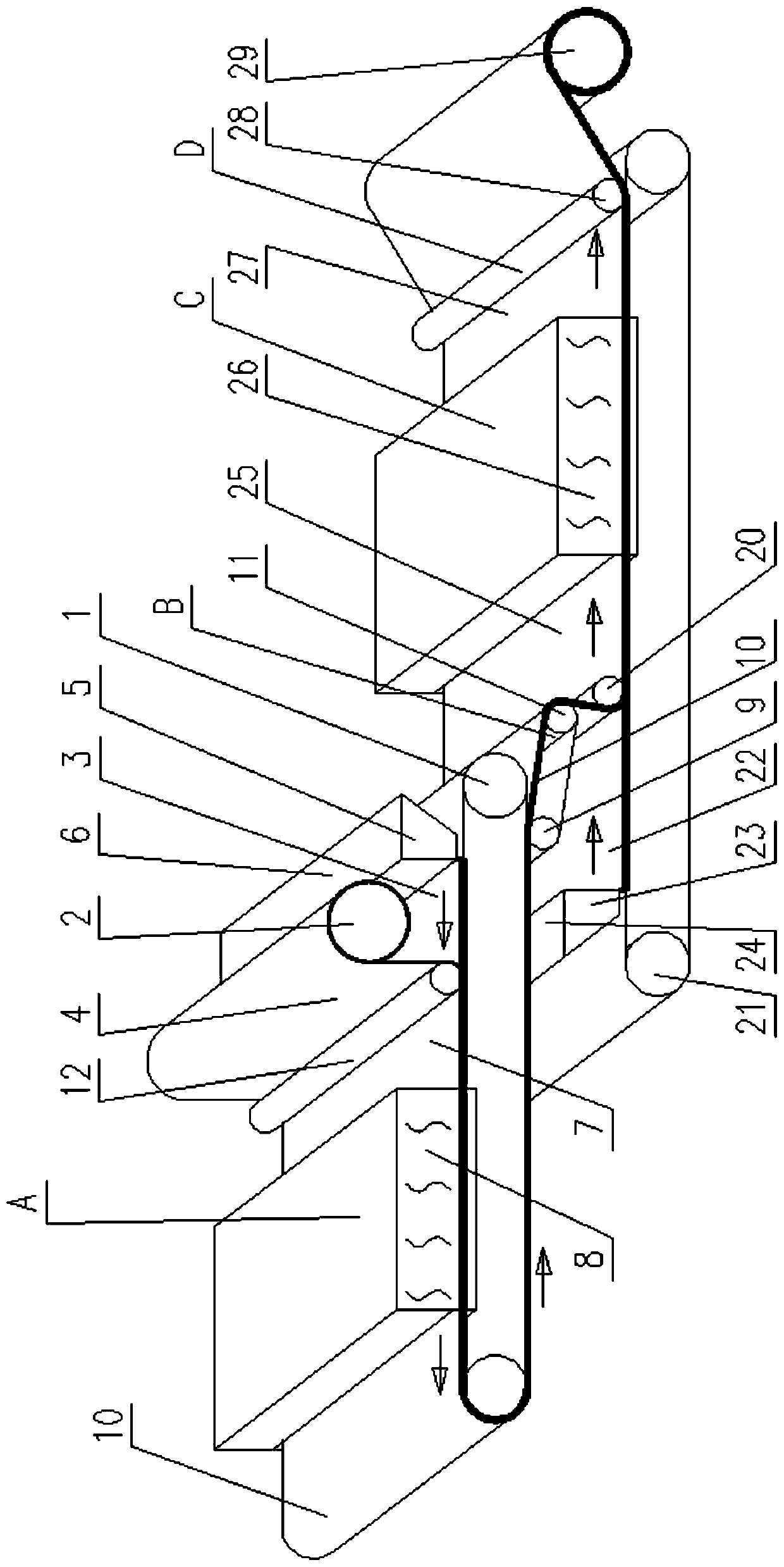

[0091] Such as figure 2 As shown, the ternary composite reconstituted tobacco sheet forming equipment of this embodiment includes a primary coating compound device A, a primary peeling conveying device B, and a secondary coating compound device C arranged in sequence according to the ternary compound reconstituted tobacco sheet forming process , Secondary peeling transfer device D.

[0092] Wherein the primary coating compound device A comprises the first conveying device 1, and the first coating device 5, the first conveying device 2 and the first covering kneading device 12 arranged on the upper right side of the first conveying device 1, and the first covering kneading device 12 arranged on the first conveying device 1 A first drying device 8 in the middle section of the conveying device 1 .

[0093] The primary peeling conveying device B is arranged below the primary coating composite device A, and the primary peeling conveying device B includes a first peeling device 9 ...

Embodiment 2

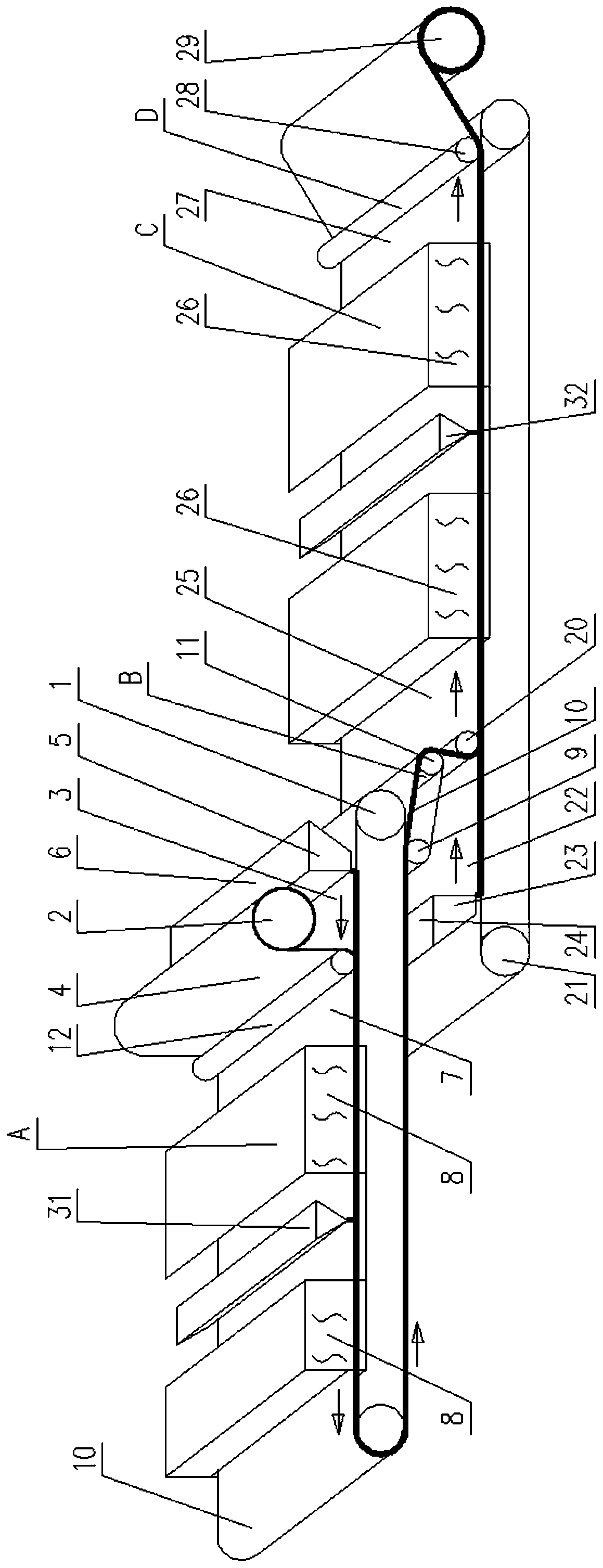

[0101] Such as image 3 As shown, the ternary composite reconstituted tobacco sheet forming equipment of this embodiment includes a primary coating compound device A, a primary peeling conveying device B, and a secondary coating compound device C arranged in sequence according to the ternary compound reconstituted tobacco sheet forming process , Secondary peeling transfer device D.

[0102] Wherein the primary coating compound device A comprises the first conveying device 1, and the first coating device 5, the first conveying device 2 and the first covering kneading device 12 arranged on the upper right side of the first conveying device 1, and the first covering kneading device 12 arranged on the first conveying device 1 A first drying device 8 in the middle section of the conveying device 1 , and a third coating device 31 located in the middle section of the first drying device 8 .

[0103] The primary peeling conveying device B is arranged below the primary coating composi...

Embodiment 3

[0112] Such as Figure 4 As shown, the ternary composite reconstituted tobacco sheet forming equipment of this embodiment includes a primary coating compound device A, a primary peeling conveying device B, and a secondary coating compound device C arranged in sequence according to the ternary compound reconstituted tobacco sheet forming process , Secondary peeling transfer device D.

[0113] Wherein the primary coating compound device A comprises the first conveying device 1, and the first coating device 5, the first conveying device 2 and the first covering kneading device 12 arranged on the upper right side of the first conveying device 1, and the first covering kneading device 12 arranged on the first conveying device 1 The first drying device 8 in the middle section of a conveying device 1, and the first spraying device 33 located on the left side of the first coating device 5;

[0114] The primary peeling conveying device B is arranged below the primary coating composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com