Paper filter stick for reducing phenolic compounds in cigarette smoke

A technology for phenolic substances and cigarette smoke, applied in papermaking, textiles and papermaking, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve the problem of low interception efficiency of phenolic substances, and achieve overcoming thermal collapse, Effect of reducing tar and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

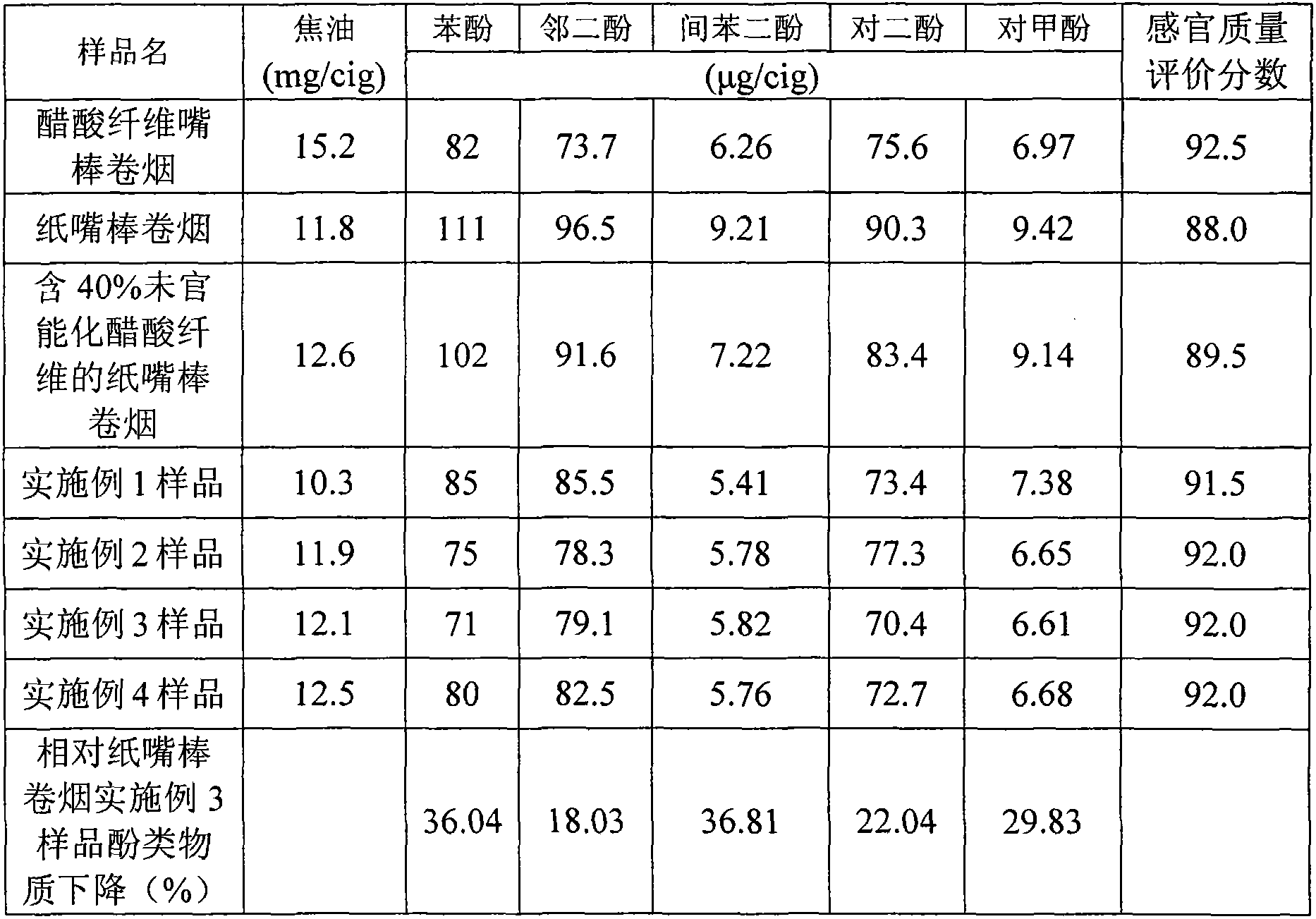

Embodiment 1

[0027] Dissociate the waste silk from the mouth stick factory or the acetate fiber factory through disc grinding, soak it with 30% aqueous solution of isopropanolamine at 30°C for 3 hours, then filter and wash with deionized water to obtain the amino functional cellulose diacetate. According to the weight ratio of 1:5, the amino-functionalized diacetate fiber was mixed with the disc-refined wood pulp, and the paper was made by wet process, and the basis weight was 23g / m 2 Paper containing amine-functionalized diacetate cellulose. The paper was embossed, cut into 23cm wide narrow strips, made into filter rods with a mouth rod forming machine, and rolled into cigarettes. The equipment operated normally, improved the taste, and reduced tar and phenol The role of substances is obvious.

Embodiment 2

[0029] Dissociate the waste silk from the mouth stick factory or the acetate fiber factory through disc grinding, soak it with 20% polyethyleneimine aqueous solution at 50°C for 4 hours, then filter and wash with deionized water to obtain the amino functional cellulose diacetate. According to the weight ratio of 2:3, the amino-functionalized diacetate fiber was mixed with the disc-refined hemp pulp, and the paper was made by wet method to obtain a quantitative value of 30g / m 2 Paper containing amine-functionalized diacetate cellulose. The paper was embossed, cut into 18cm wide narrow strips, made into filter rods with a mouth rod forming machine, and rolled into cigarettes. The equipment operated normally, improved the taste, and reduced tar and phenol The role of substances is obvious.

Embodiment 3

[0031] Dissociate the waste silk from the mouth stick factory or the acetate fiber factory through disc grinding, soak in 25% chitosan aqueous solution at 60°C for 5 hours, then filter and wash with deionized water to obtain amine functionalized of cellulose diacetate. According to the weight ratio of 3:3, the amino-functionalized diacetate fiber was mixed with the disc-refined wood pulp, and the paper was made by wet process, and the basis weight was 35g / m 2 Paper containing amine-functionalized diacetate cellulose. The paper was embossed, cut into 27cm wide narrow strips, made into filter rods with a mouth rod forming machine, and rolled into cigarettes. The equipment operated normally, improved the taste, and reduced tar and phenol The role of substances is obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com