Preparation method of xanthate

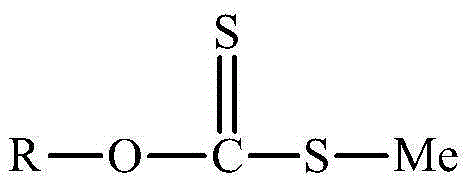

A technology of xanthate and raw materials, which is applied in the field of preparation of xanthate compounds, can solve problems such as unfavorable alkali dispersion or dissolution, difficult separation of xanthate, and strong pungent odor, so as to avoid irritating Odor, high conversion rate of raw materials, light odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

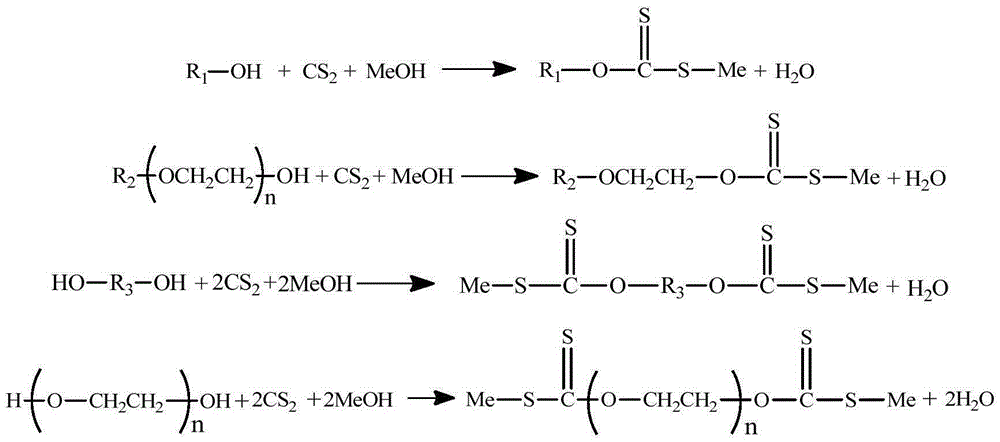

Method used

Image

Examples

Embodiment 1 10

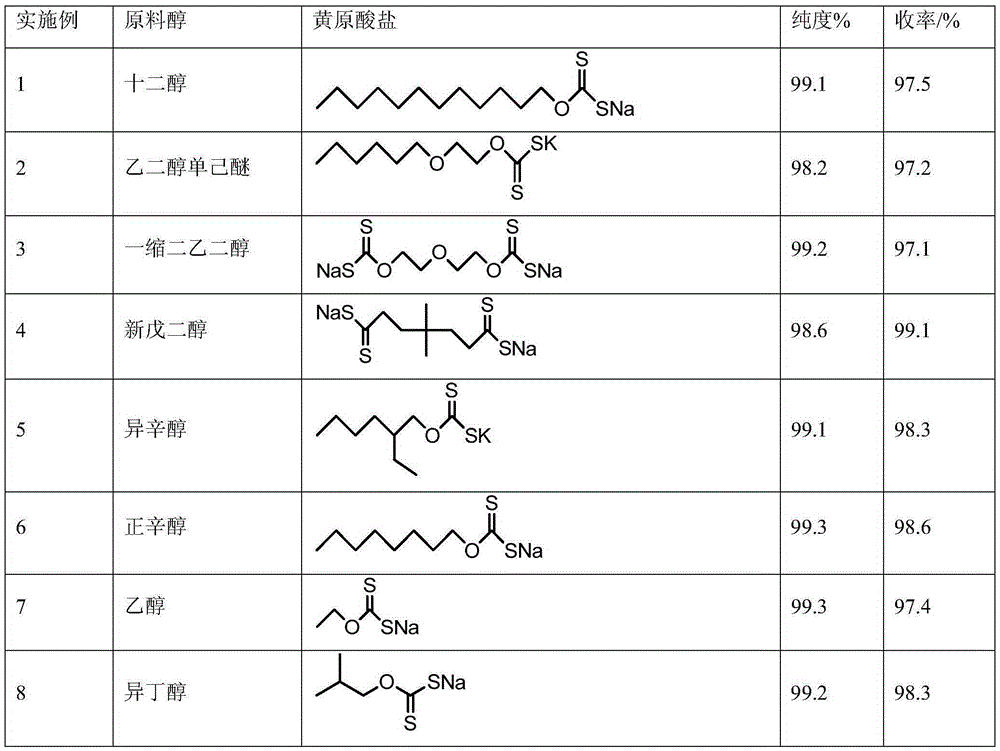

[0049] The preparation of embodiment 1 sodium dodecyl xanthate

[0050] Add 17.78 parts of tetrahydrofuran with a purity of 99% into the reactor, start stirring, add 18.63 parts of dodecanol with a purity of 99%, stir for 10 minutes, and add 4.2 parts of granular sodium hydroxide with a purity of 96% in batches. In a container, fully stir for 20 minutes at 5-20°C. Then slowly add 7.84 parts of carbon disulfide, and then stir and react at 10-20°C for 3 hours after the addition. After the reaction was completed, the reaction mixture was distilled and dried to obtain a sodium dodecyl xanthate product with a purity of 99.1%. The product had a light odor and was non-irritating. The yield based on dodecyl alcohol was 97.5%.

Embodiment 2

[0051] The preparation of embodiment 2 hexyloxyethyl xanthate potassium

[0052] Add 13.33 parts of tetrahydrofuran with a purity of 99% into the reactor, start stirring, and add a total of 6.6 parts of flake potassium hydroxide (purity 85%) into the reactor in batches, stir well; slowly add 14.92 parts at 5 to 20°C Parts of ethylene glycol monohexyl ether with a purity of 98% were added, and stirring was continued for 10 minutes after the addition was complete. Then slowly add 7.74 parts of carbon disulfide, and then stir and react at 10-22°C for 2.5 hours after the addition. After the reaction was completed, the reaction mixture was distilled and dried to obtain a potassium hexyloxyethyl xanthate product with a purity of 98.2%. The product had a light odor and was non-irritating. The product yield based on ethylene glycol monohexyl ether was 97.2%.

Embodiment 3

[0053] Embodiment 3 diethylene glycol and sodium hydroxide prepare sodium dixanthate

[0054] Add 13.33 parts of tetrahydrofuran with a purity of 99% into the reactor, start stirring, and add 4.3 parts of granular sodium hydroxide (purity 96%) in batches to the reactor, stir well; slowly add 5.31 Parts of diethylene glycol with a purity of 99% were stirred and reacted for 20 minutes after the addition was completed. Then slowly add 7.91 parts of carbon disulfide, and then stir and react at 10-22°C for 2.5 hours after the addition. After the reaction was completed, the reaction mixture was distilled and dried to obtain a sodium diethylene glycol dixanthate product with a purity of 99.2%. The product had a light smell and was non-irritating. The yield based on diethylene glycol was 97.1%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com