Environmentally-friendly waterproof material for buildings

A waterproof material, environmentally friendly technology, applied in the direction of coating, can solve the problems of shortened service life, surface damage, poor environmental protection performance, etc., to achieve the effect of improving environmental protection performance, prolonging service life, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

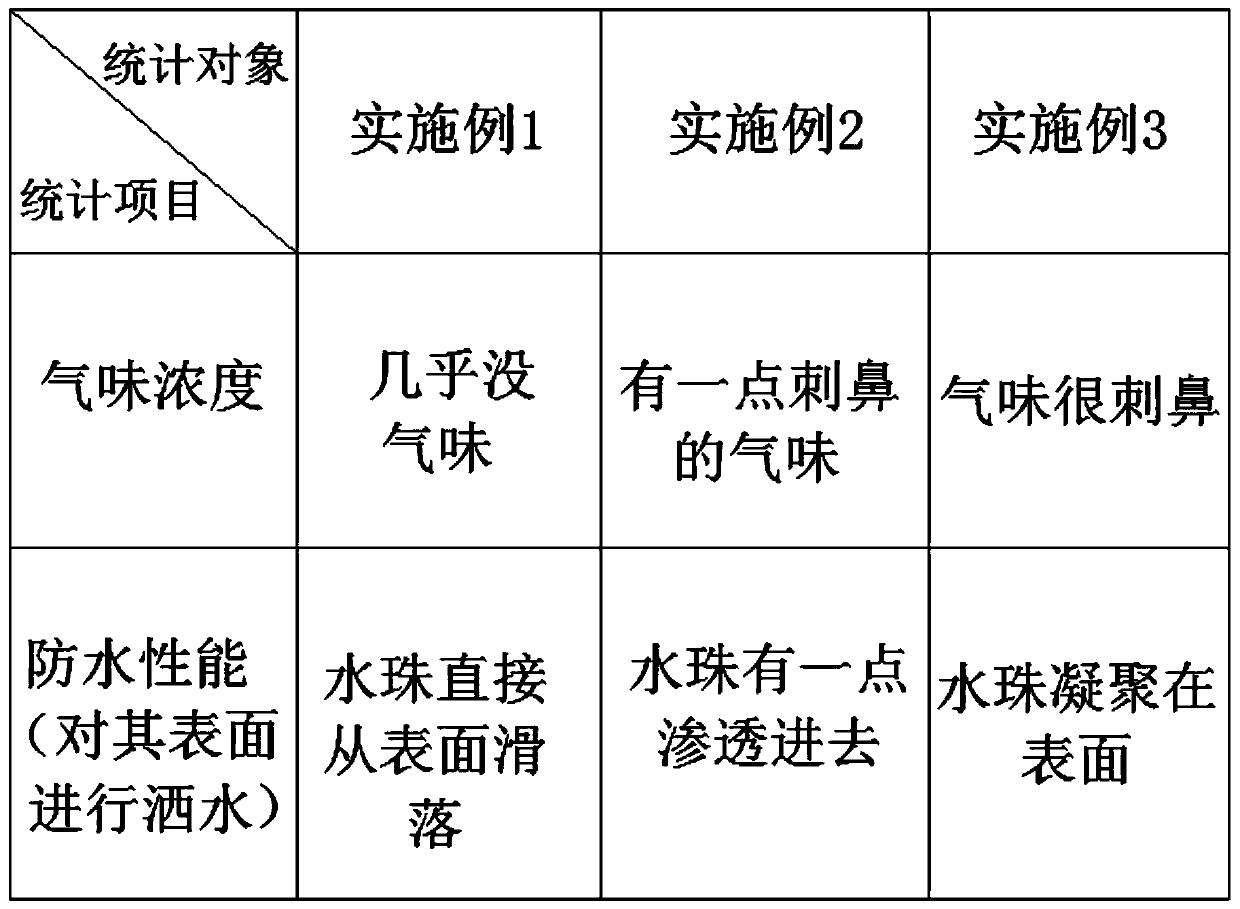

Examples

Embodiment 1

[0028] S1. Select 35 parts of acrylic acid, 25 parts of epoxy resin glue, 12 parts of thickener, 4 parts of compatibilizer, 6 parts of antioxidant and 2 parts of defoamer, mix and stir the raw materials, and then heat it up to 100 ℃, continue stirring to make it evenly heated, the stirring speed is 80 rpm, and the stirring time is 40 minutes;

[0029] S2. Weigh 11 parts of elastic fiber, 5 parts of antistatic agent, 9 parts of lubricant and 7 parts of filler, pour it into the mixture prepared in step S1, stir and mix, the speed of stirring is 80 rpm, and the stirring time is 40 minutes, after mixing evenly, dissolve and polymerize for 7 hours;

[0030] S3, add 4 parts of solvents, 20 parts of epoxy resin curing agent and 8 parts of pigments, stir and mix, make it mix evenly, the speed of stirring is 150 rpm, and the stirring time is 65 minutes, after the stirring is completed, it is cooled to At room temperature, an environmentally friendly waterproof material for constructio...

Embodiment 2

[0032] S1. Select 25 parts of acrylic acid, 15 parts of epoxy resin glue, 8 parts of thickener, 3 parts of compatibilizer, 2 parts of antioxidant and 1 part of defoamer, mix and stir the raw materials, and then heat it up to 90 ℃, continue stirring to make it evenly heated, the stirring speed is 60 rpm, and the stirring time is 30 minutes;

[0033] S2, weigh 8 parts of elastic fiber, 2 parts of antistatic agent, 6 parts of lubricant and 4 parts of filler, pour it into the mixture prepared in step S1, stir and mix, the speed of stirring is 60 rpm, and the stirring time is 30 minutes, after mixing evenly, dissolve and polymerize for 6 hours;

[0034] S3, add 1 part of solvent, 10 parts of epoxy resin curing agent and 4 parts of pigment, stir and mix, make it mix evenly, the speed of stirring is 110 rpm, and the stirring time is 50 minutes, after the stirring is completed, it is cooled to At room temperature, an environmentally friendly waterproof material for construction can b...

Embodiment 3

[0036]S1. Select 45 parts of acrylic acid, 35 parts of epoxy resin glue, 16 parts of thickener, 6 parts of compatibilizer, 10 parts of antioxidant and 3 parts of defoamer, mix and stir the raw materials, and then heat it up to 110 ℃, continue stirring to make it evenly heated, the stirring speed is 100 rpm, and the stirring time is 50 minutes;

[0037] S2. Weigh 14 parts of elastic fiber, 8 parts of antistatic agent, 12 parts of lubricant and 10 parts of filler, pour it into the mixture prepared in step S1, stir and mix, the speed of stirring is 100 rpm, and the stirring time is 50 minutes, after mixing evenly, dissolve and polymerize for 8 hours;

[0038] S3, add 6 parts of solvent, 30 parts of epoxy resin curing agent and 12 parts of pigment, stir and mix to make it evenly mixed, the stirring speed is 180 rpm, and the stirring time is 80 minutes. After the stirring is completed, let it cool to room temperature , you can get environmentally friendly waterproof materials for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com