Cr and V alloying beta phase solidifying high Nb-TiAl alloy and preparation method thereof

A technology of alloying and alloying, applied in the field of alloys, to achieve the effect of simple process and easy operation of process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

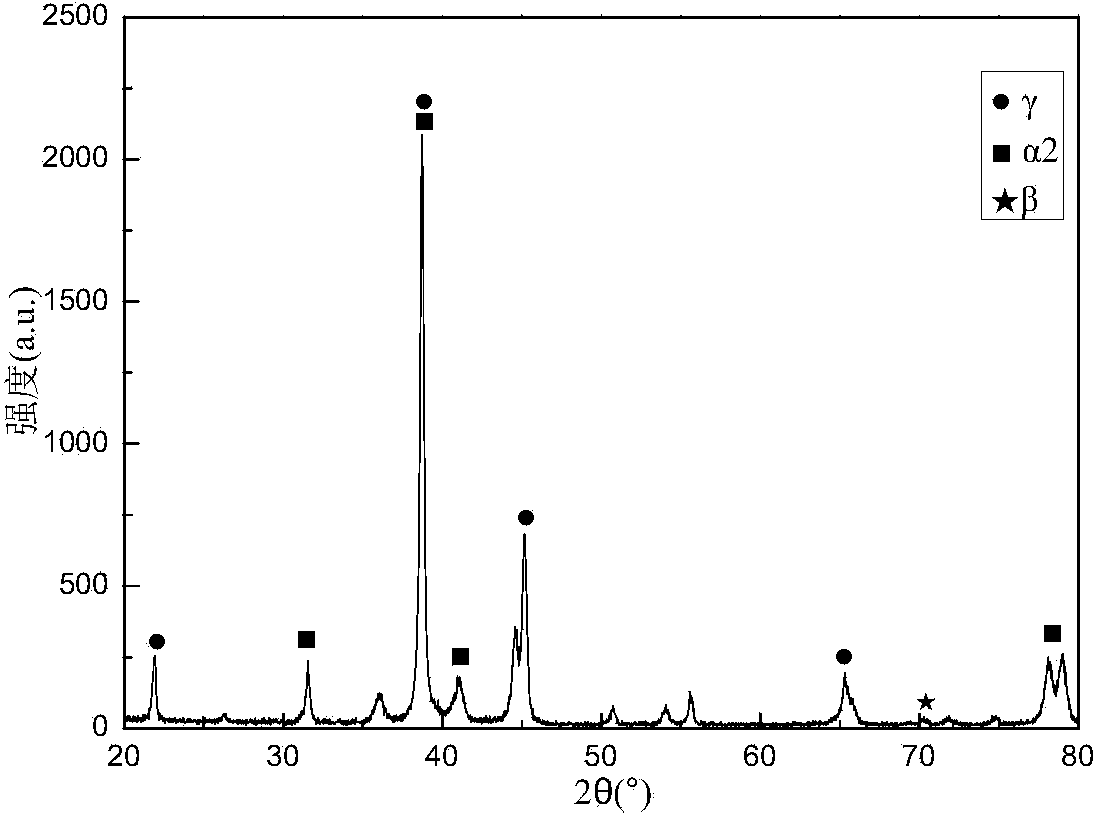

[0024] The preparation of Cr, V alloyed β-phase solidified high Nb-TiAl alloy in this embodiment is realized through the following steps: 1. Weigh the following raw materials: sponge titanium, high-purity aluminum, aluminum-niobium master alloy, electrolytic chromium sheet and aluminum-vanadium intermediate Alloys, wherein Ti46at.%, Al45at.%, Nb8at.%, Cr0.5at.%, V0.5at.%; 2. The raw materials weighed in step 1 are carried out into briquettes through a metal briquetting machine. When briquetting, first Place the sponge titanium on the inner edge of the mold, and then place the high-purity aluminum layer, the aluminum-niobium master alloy layer, the electrolytic chromium sheet layer, the aluminum vanadium master alloy layer and the sponge titanium layer from bottom to top inside the area surrounded by the sponge titanium Layer; 3. Put the briquette obtained in step 2 into a water-cooled copper crucible vacuum induction melting furnace that can be centrifugally poured. Before melt...

Embodiment 2

[0027] The preparation of Cr, V alloyed β-phase solidified high Nb-TiAl alloy in this embodiment is realized through the following steps: 1. Weigh the following raw materials: sponge titanium, high-purity aluminum, aluminum-niobium master alloy, electrolytic chromium sheet and aluminum-vanadium intermediate Alloy, wherein Ti48.8at.%, Al43at.%, Nb8at.%, Cr0.1at.%, V0.1at%; 2. The raw materials weighed in step 1 are carried out into briquettes by a metal briquetting machine. When briquetting First place the sponge titanium on the inner edge of the mold, and then place the high-purity aluminum layer, the aluminum-niobium master alloy layer, the electrolytic chromium sheet layer, the aluminum vanadium master alloy layer and the sponge titanium layer from bottom to top inside the area surrounded by the sponge titanium. Layer; 3. Put the briquette obtained in step 2 into a water-cooled copper crucible vacuum induction melting furnace that can be centrifugally poured. Vacuum to 1.2×1...

Embodiment 3

[0030] The preparation of Cr, V alloyed β-phase solidified high Nb-TiAl alloy in this embodiment is realized through the following steps: 1. Weigh the following raw materials: sponge titanium, high-purity aluminum, aluminum-niobium master alloy, electrolytic chromium sheet and aluminum-vanadium intermediate Alloys, wherein Ti47.25at.%, Al44at.%, Nb8at.%, Cr0.25at.%, V0.5at%; 2. The raw materials weighed in step 1 are carried out into briquettes by a metal briquetting machine. When briquetting First place the sponge titanium on the inner edge of the mold, and then place the high-purity aluminum layer, the aluminum-niobium master alloy layer, the electrolytic chromium sheet layer, the aluminum vanadium master alloy layer and the sponge titanium layer from bottom to top inside the area surrounded by the sponge titanium. 3. Put the briquette obtained in step 2 into a water-cooled copper crucible vacuum induction melting furnace that can be centrifugally poured. Before melting, preh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com