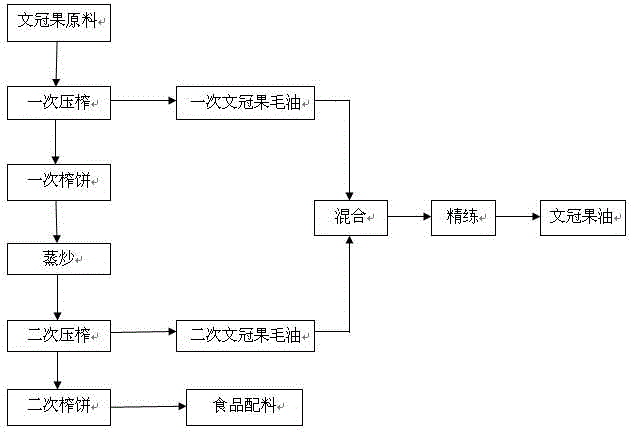

Method for preparing shiny-leaved yellowhorn oil by secondary pressing

A technology of secondary pressing and sorbifolium fruit oil, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc. It can solve the problems of unfriendly solvent gas environment, hidden dangers of organic solvent safety, high cost of enzyme use, etc., to achieve Increased oil yield, fewer supporting equipment, and flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] Step 1. Preparation of raw materials of X. sorbifolium: select X. sorbifolia and crush to remove part of the shell of X. sorbifolia, and retain 10% to 15% of the shell content to increase the friction of pressing. If pure X. sorbifolia is used Kernel pressing, because the material is compacted, the oil channel will be lost, and the oil yield will be greatly reduced, leaving 10-15% of the radishes to adjust the plasticity of the pressing material, and the pressing effect is excellent, and then use mixed-flow hot air drying machine, using hot air as the drying medium, to dry the kernel and shell of the crushed sorbifolium sorbifolium until the moisture content is 4-6%, so as to facilitate oil extraction;

[0020] Step 2, one-time pressing: Carry out one-time pressing on the raw material of sorbifolium sorbifolium prepared in step 1 to obtain one-time sorbifolium crude oil and one-time pressing cake, wherein, the conditions of one-time pressing are: pressing temperature 60-...

Embodiment 1

[0030] Dried the sorbifolium with a shell content of 10% to a moisture content of 6%, pressed at a temperature of 100°C, and pressed for 0.5 hours to obtain primary sorbiflora crude oil and a primary cake, and moistened the primary cake to a moisture content of 16 %, steaming and frying layer by layer, steam pressure 0.1Mpa, steaming temperature 100±5°C, steaming thickness 30cm, steaming time 20 minutes, until the moisture content of the first pressed cake is 10%; The second pressing, the pressing temperature is 80°C, the pressing time is 0.5h, to obtain the second Xeroxio sorbifolium crude oil and the second squeeze cake, mix the first Xeroxinia sorbifolium crude oil and the second Xeroxinia sorbifolium crude oil, and carry out alkali refining in sequence , dehydration, decolorization and deodorization treatment, to get the finished Xanthan fruit oil, the oil extraction rate is 92.4%.

Embodiment 2

[0032] Dried sorbifolia with a shell content of 10% to a moisture content of 5%, pressed at a temperature of 115°C, and pressed for 1 hour to obtain primary sorbifolium crude oil and a primary cake, and moistened the primary cake to a moisture content of 15% , steaming and frying layer by layer, steam pressure 0.1Mpa, steaming temperature 100±5°C, steaming thickness 20cm, steaming time 25 minutes, until the moisture content of the first pressed cake is 9%; Squeeze, the pressing temperature is 120°C, and the pressing time is 1h, to obtain the second sorbiola crude oil and the second pressing cake, mix the primary sorbiola crude oil and the second sorbiola crude oil, and carry out alkali refining and dehydration in sequence , decolorization and deodorization treatment, to get the finished Xanthan fruit oil, the oil extraction rate is 94.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com