Method for determining road roller compacted concrete composition based on pressing vibration method

A technology of roller compacted concrete and vibration method, which is applied in the field of determining the mix ratio of road roller compacted concrete based on the pressure vibration method, which can solve the problems of large consistency, cumbersome test steps, time-consuming and laborious, etc., and achieve high compaction and simple operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] The instrument equipment used in the present invention comprises:

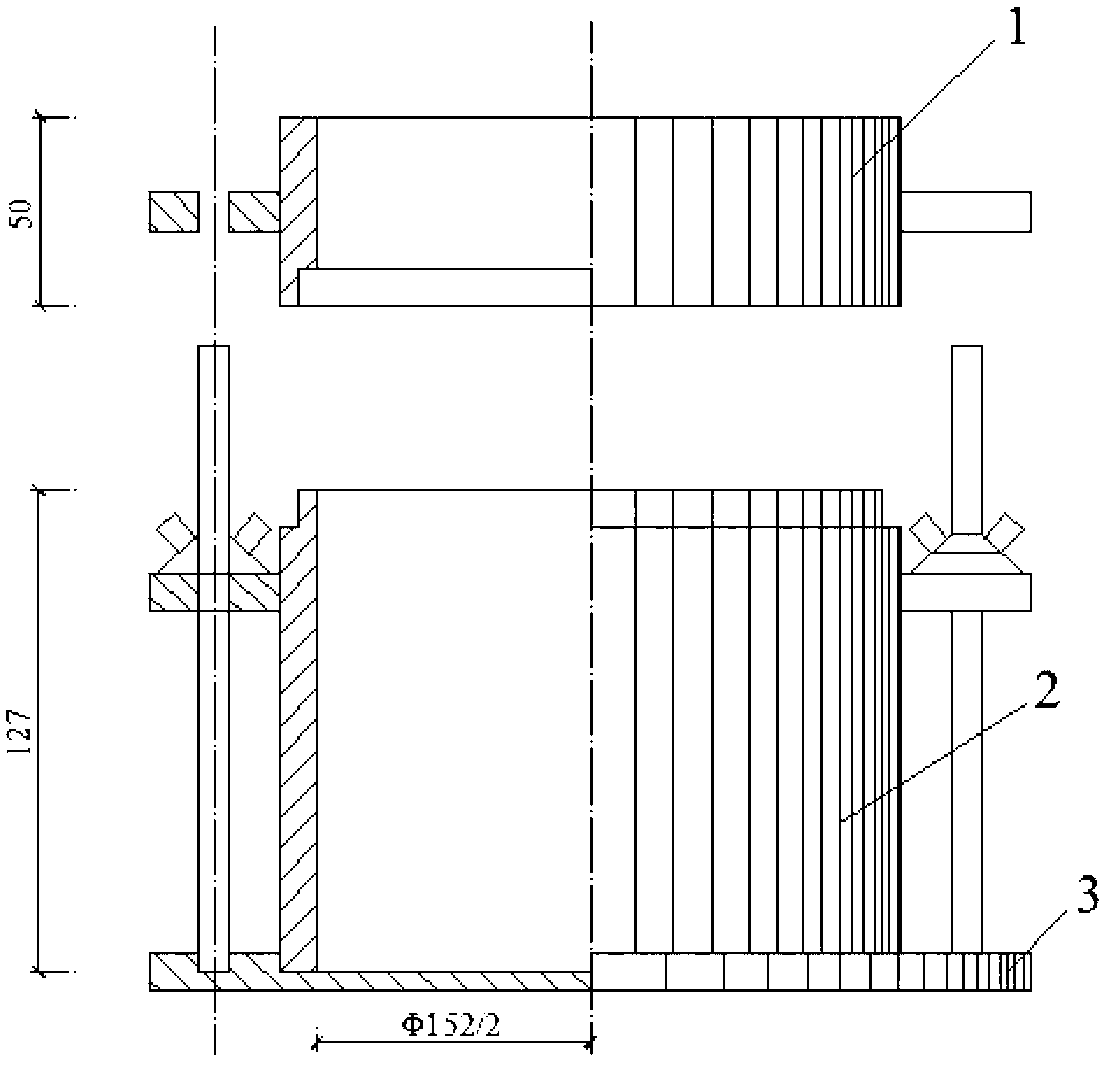

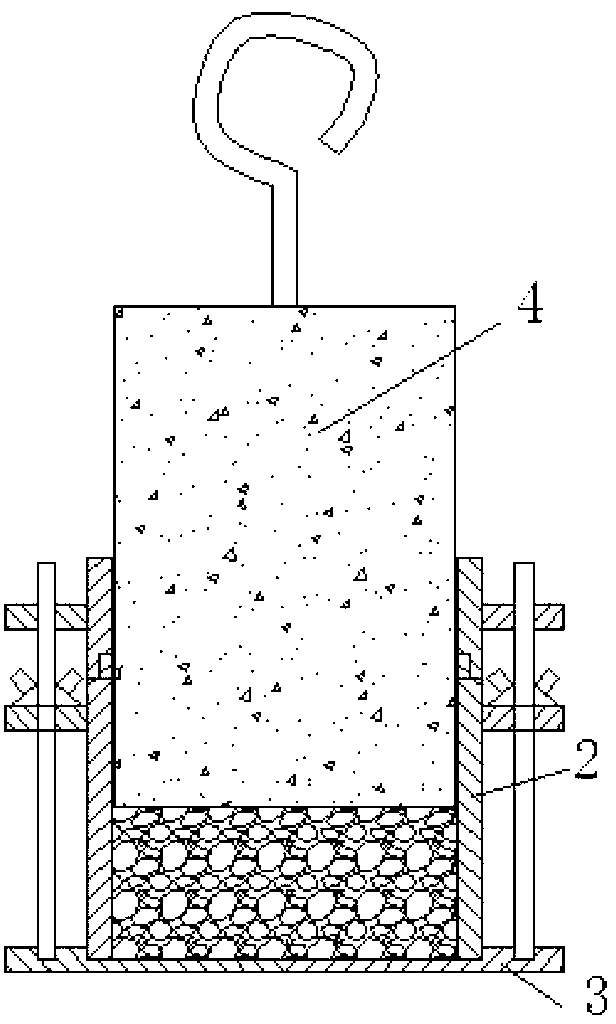

[0032] refer to figure 1 , figure 1 It is a schematic diagram of the sleeve 1, the capacity cylinder 2 and the bottom plate 3. Capacity cylinder 2: the inner diameter is 152.0±0.5mm, the inner height is 127.0±0.5mm, and the wall thickness is 10.0mm. The inner diameter and wall thickness of sleeve 1 are the same as those of capacity cylinder 2, and the height is 50.0mm.

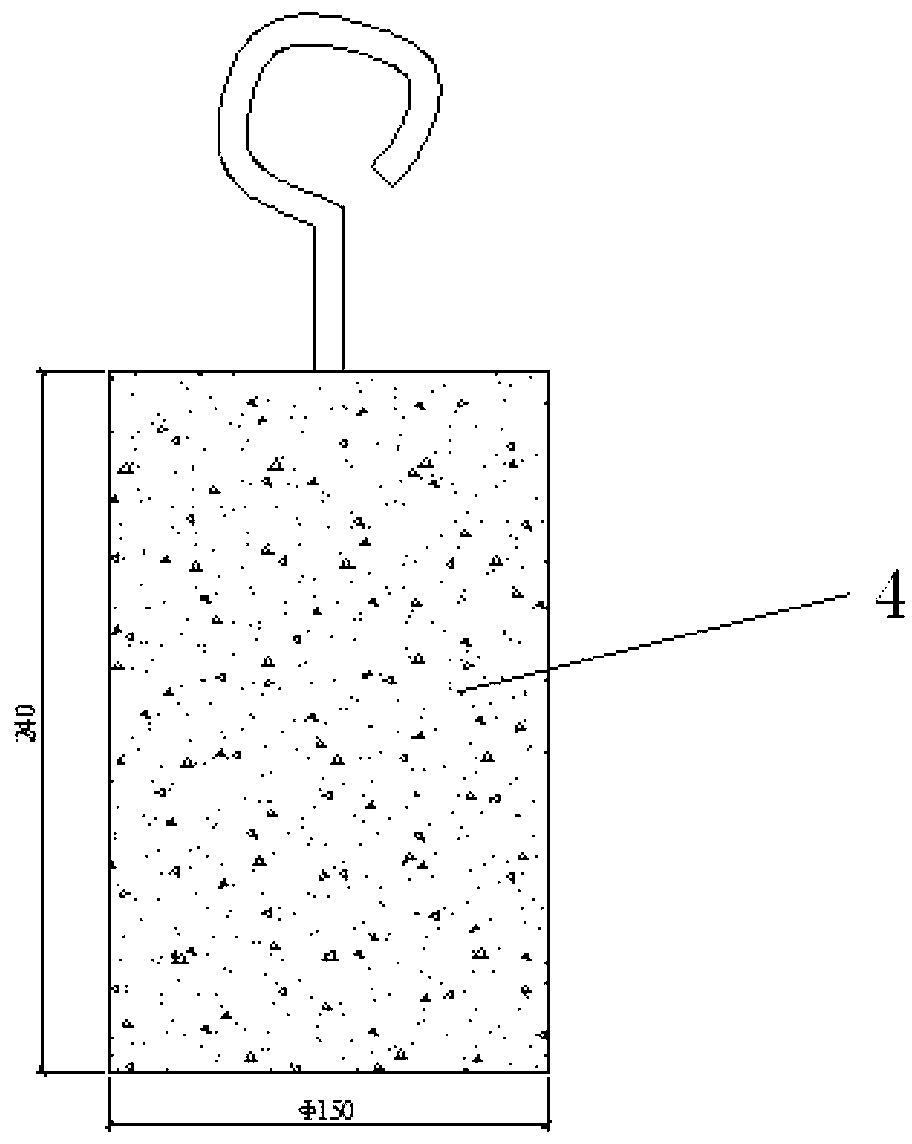

[0033] refer to figure 2 , figure 2 It is a schematic diagram of load-bearing briquetting block 4. Load-bearing pressing block 4: a cylindrical block with a total weight of 10.0kg, a pressure-applying section diameter of 150.0mm, and a height of 240.0mm, and the pressure-applying surface should be smooth and flat.

[0034] Concrete magnetic vibrating table: the working frequency is not less than 50Hz, and the amplitude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com