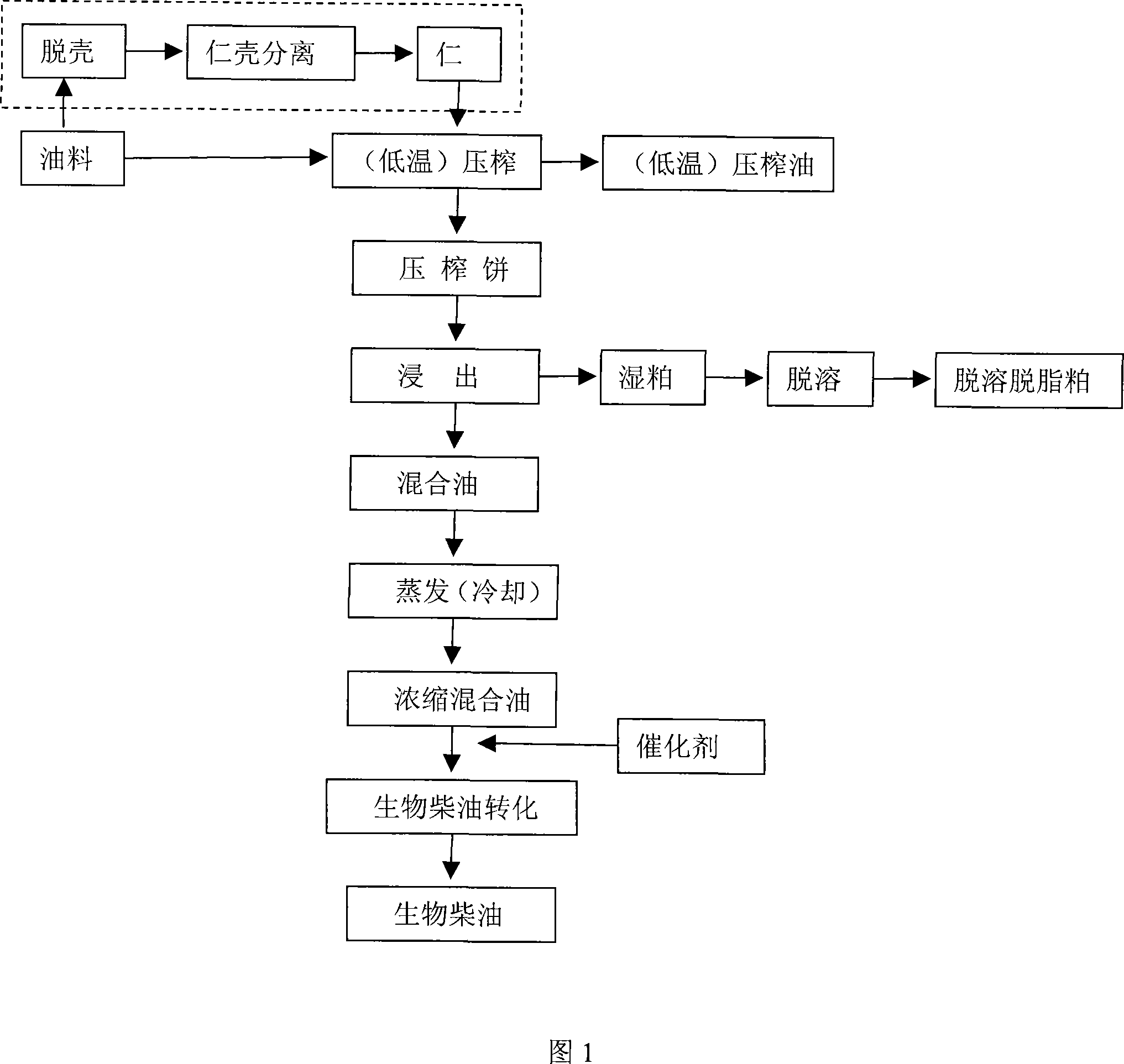

Method for extracting conversion biodiesel from oil pressing cake

A technology of biodiesel and press cake, which is applied in the processing of oil press cake, biodiesel and degreased meal, can solve the problems of adverse effects on human health, energy loss, increased consumption, etc., to improve comprehensive utilization value, reduce investment, reduce The effect of intermediate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The rapeseed containing 0.23% of impurities by weight is put into the rolling machine after the plane rotary sieve, de-stoner, magnetic separator and winnowing, and the granular oil is rolled into a thin green sheet with a thickness of 0.3 mm. A vertical steamer is used to steam and fry the flakes. After steaming and frying, the weight ratio of the water content is 5%, and the temperature of the blank is 110°C. The cooked embryos after steaming and frying are directly entered into the ZY24 pre-pressing machine for pressing. After pressing, the residual oil ratio of the rapeseed cake is 12.5% by weight. The pressed cake enters the extractor and uses n-hexane as a solvent to extract oil. The extraction temperature is 55°C. The leaching time is 120 minutes, the charging height of the grid is 1.1 meters, and the solvent spraying volume is 1.2m 3 / h. The wet meal obtained by leaching enters the DT steamer for desolventization. The direct steam pressure of the DT steamer i...

Embodiment 2

[0028] Dry the rapeseed containing 0.3% impurities by weight after passing through the plane rotary sieve, de-stoner, magnetic separator and winnowing, the water content after drying is 9% by weight, and the dried rapeseed is used YTTP-75 type dehulling and separation system performs dehulling and kernel-hull separation to obtain rapeseed kernels. The skin content in the kernels is 1.93% by weight, and the SSYZ 12 / 12 low-temperature screw oil press is used to feed at room temperature and squeeze to obtain The low-temperature press cake with a residual oil rate of 14.8% by weight, the press cake enters the extruder for expansion, and the expanded material enters the leaching device for leaching with isopropanol, the leaching temperature is 78 ° C, the time is 120 minutes, and the charging height of the material grid is 1.0 m, solvent spray volume is 1.5m 3 / h. The wet meal obtained by leaching is subjected to DT steaming and off-line for desolventization, and the residual oil ...

Embodiment 3

[0033] Dry the rapeseeds containing 0.26% impurities by weight after passing through the plane rotary sieve, de-stoner, magnetic separator and winnowing. The water content after drying is 8.5% by weight. The dried rapeseeds are used YTTP-75 shelling and separation system is used for shelling and kernel-hull separation to obtain rapeseed kernels. The skin content in the kernels is 1.53% by weight. The SSYZ 12 / 12 low-temperature screw oil press is used to feed at room temperature and press Obtain the low-temperature pressed cake with 15.2% residual oil rate by weight, the pressed cake enters the extruder and expands, and the material after the expansion enters the extractor and is leached with acetone-ethyl acetate mixed solvent, and the weight ratio of acetone and ethyl acetate in the mixed solvent is 7:3, the leaching temperature is 40°C, the time is 120 minutes, the charging height of the material grid is 1.2 meters, and the solvent spraying volume is 1.4m 3 / h. The wet meal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com