Beet processing process and unit

A processing technology and sugar beet technology, applied in the field of sugar beet processing technology and devices, can solve the problems of cumbersome, increased product cost, expensive equipment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

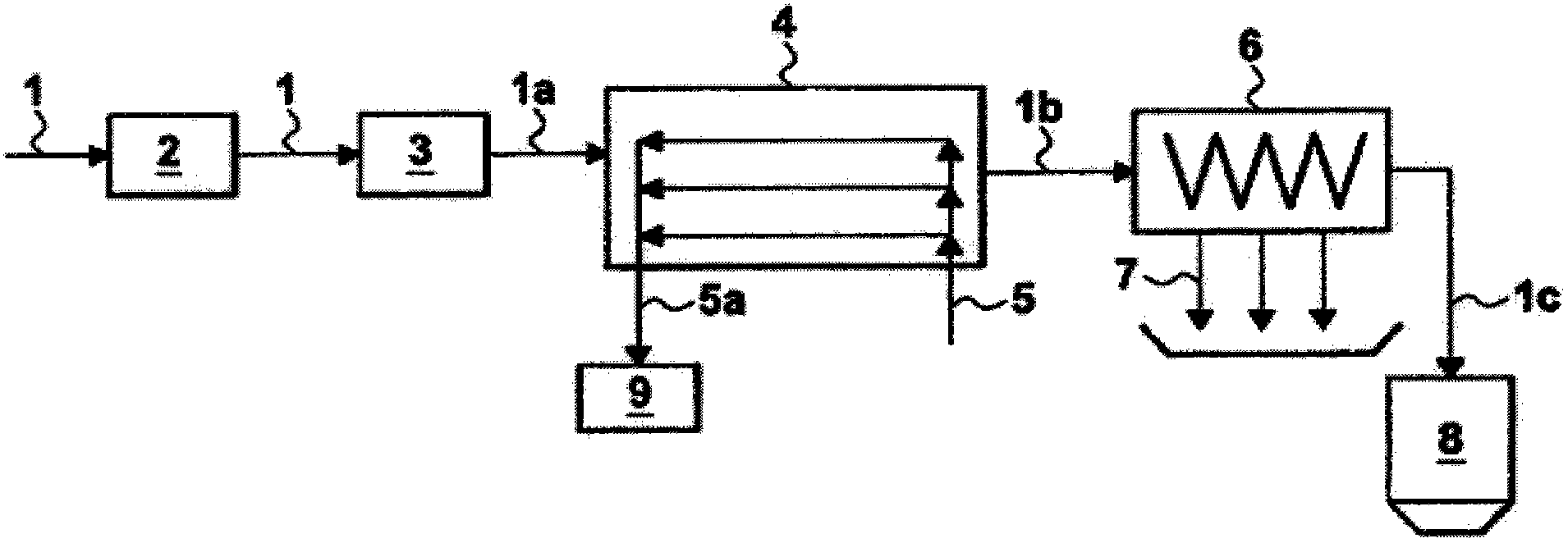

Method used

Image

Examples

Embodiment approach

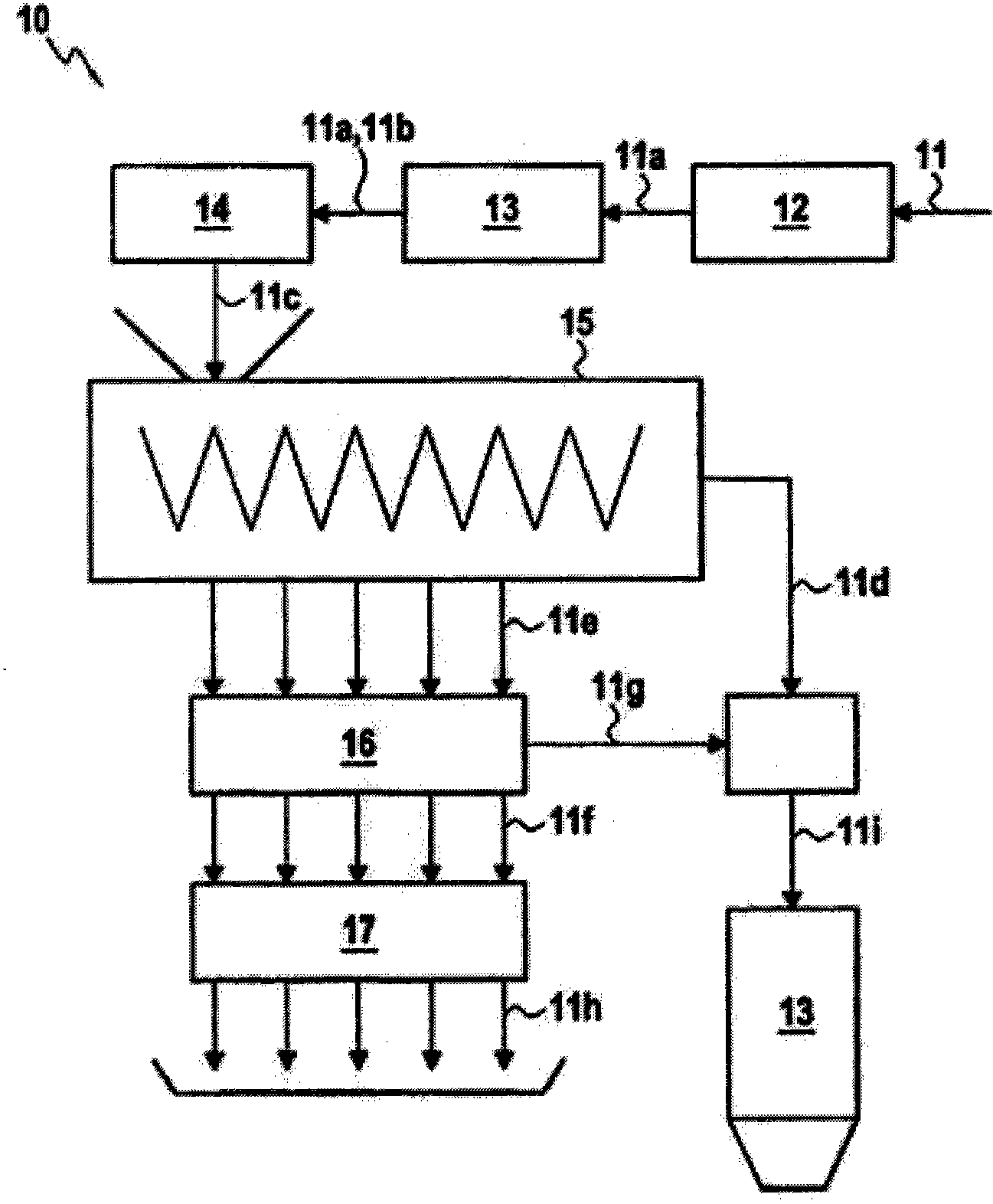

[0069] according to figure 2 In the first embodiment shown, the plant 10 for carrying out the sugar beet processing process additionally makes it possible to obtain two end products, i.e. on the one hand a mixture of press cake and filter cake and on the other hand a filtered syrup with About 90% purity and more than 60% dry matter content, brown in color. Such as figure 2 As shown, the sugar beet 11 enters the cleaning device 12 . These washed beets 11 a are optionally chopped in a chopping device 13 . Preferably, the washed whole 11a or shredded 11b beets are then heated in a heating device 14, for example consisting of a 100°C steam pan. The heated 11c whole or chopped sugar beet then enters a pressing device 15, for example a twin-screw press known to a person skilled in the art, which performs a partial pressing so that at the outlet two separate products are obtained: on the one hand a relative Sugar beet press cake 11d with a dry matter content of more than 20% su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com