Utilization method of acid remelted iron powder

A technology for regenerating iron powder and iron scale with acid, applied in furnaces, furnace types, fluidized bed furnaces, etc., can solve the problems of environmental pollution metal yield and low cost, and achieve the effect of low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

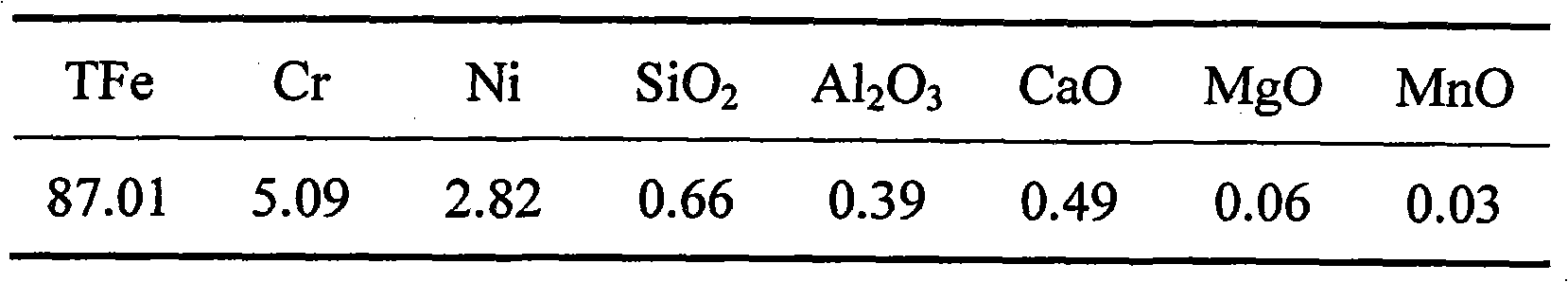

[0026] The embodiment of the method utilizing acid regenerated iron powder and iron scale to produce sponge iron is following successive steps:

[0027] (1) Mixing

[0028] Stir the acid regenerated iron powder and iron scale evenly according to the following mass ratio:

[0029] Acid Regenerated Iron Powder 40 Iron Scale 58 Coke Powder 6

[0030] Among them, the particle size of iron scale is ≤3mm, and the particle size of coke powder is ≤3mm;

[0031] Then add the binder of water 1 with a proportion of 4 by mass and mix evenly.

[0032] (2) Pressure ball

[0033] The above-mentioned mixed material is sent into a cake press machine with a belt, and is extruded into a cake under a pressure of 25MPa, (the cake diameter is 15cm, and the thickness is 5cm). The cake is naturally maintained for 3 days.

[0034] (3) into the kiln smelting

[0035] Put the pressed cake into the tank, fill and seal the material tank with coke, keep warm for 8 hours at 1300°C±10°C, cool for 6 hour...

Embodiment 2

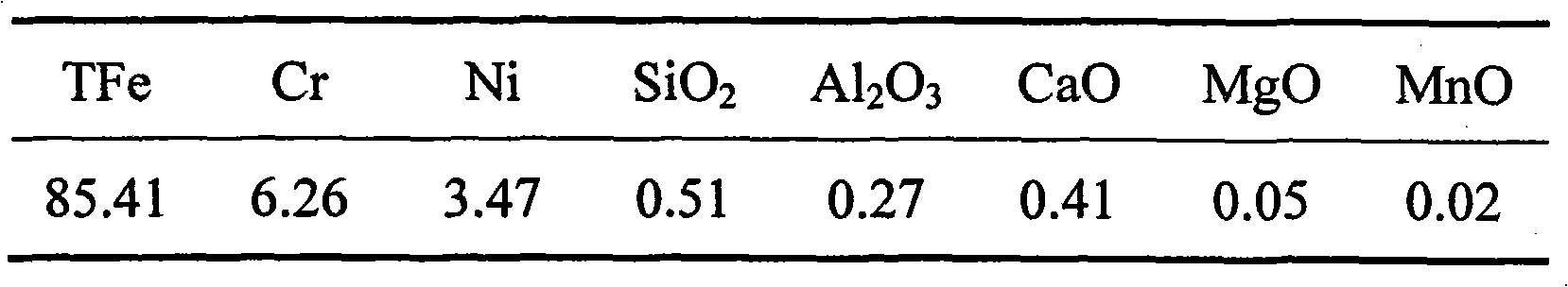

[0042] The embodiment of the method utilizing acid regenerated iron powder and iron scale to produce sponge iron is following successive steps:

[0043] (1) Mixing

[0044] Stir the acid regenerated iron powder and iron scale evenly according to the following mass ratio:

[0045] Acid Regenerated Iron Powder 50 Iron Scale 45 Coke Powder 5

[0046] Among them, the particle size of iron scale is ≤3mm, and the particle size of coke powder is ≤3mm;

[0047] Then add the binder of water 1 with a proportion of 5 by mass and mix evenly.

[0048] (2) Pressure ball

[0049] The above-mentioned mixed material is sent into a cake press machine with a belt, and is extruded into a cake under a pressure of 23MPa, (the cake diameter is 15cm, and the thickness is 5cm). The cake is naturally maintained for 3 days.

[0050] (3) into the kiln smelting

[0051] Put the pressed cake into the tank, fill and seal the material tank with coke, keep warm for 8 hours at 1300°C±10°C, cool for 6 hour...

Embodiment 3

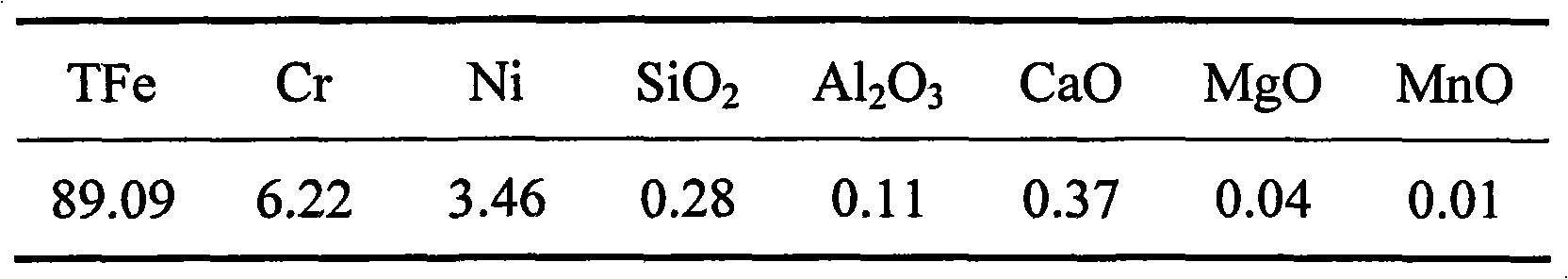

[0058] The embodiment of the method utilizing acid regenerated iron powder and iron scale to produce sponge iron is following successive steps:

[0059] (1) Mixing

[0060] Stir the acid regenerated iron powder and iron scale evenly according to the following mass ratio:

[0061] Acid Regenerated Iron Powder 50 Iron Scale 45

[0062] Among them, the particle size of iron scale is ≤3mm;

[0063] Then add the binder of water 2 with a proportion of 5 by mass and mix evenly.

[0064] (2) Pressure ball

[0065] The above-mentioned mixed material is sent into a cake press machine with a belt, and is extruded into a cake under a pressure of 30MPa, (the cake diameter is 15cm, and the thickness is 5cm) and the cake is naturally maintained for 3 days.

[0066] (3) into the kiln smelting

[0067] Put the pressed cake into the tank, fill and seal the material tank with coke, keep warm for 8h at 1300°C±10°C, cool for 6h, cool down to 200°C±10°C to form sponge iron, and leave the kiln....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com