Friction loading apparatus and method thereof

A technology of loading device and hydraulic pump station, which is applied in the direction of measuring device, machine/structural component testing, instrument, etc., can solve the problem of no loading device and method, and achieve the effect of simple structure, convenient application and uniform friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the accompanying drawings and embodiments.

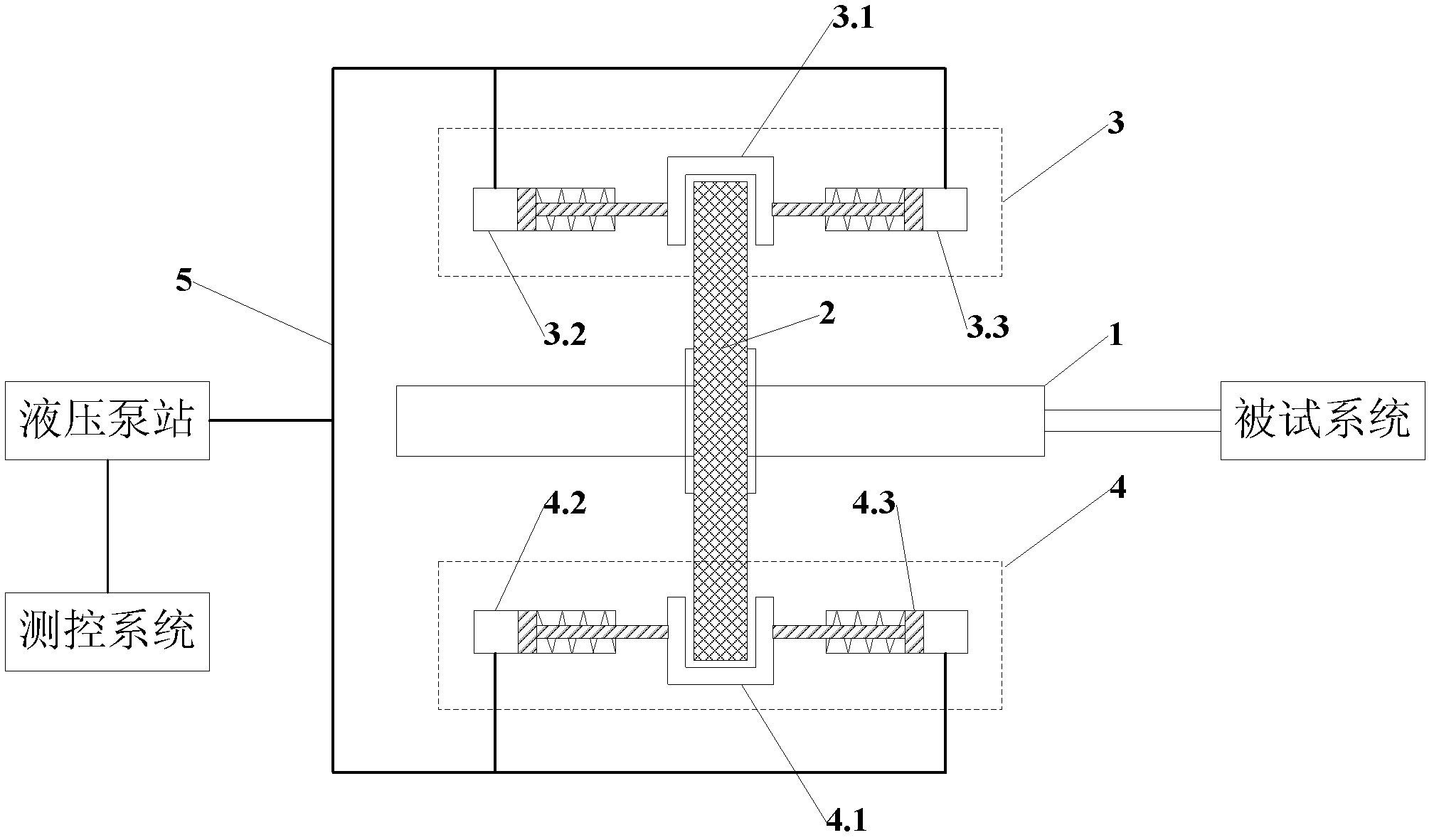

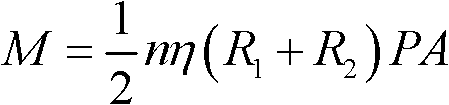

[0024] A friction loading device of the present invention, as shown in the schematic diagram in Figure 1, includes a hydraulic pump station, a braking mechanism, and a measurement and control system; wherein the braking mechanism includes a rotating shaft 1, a brake disc 2, a first brake caliper 3 and The second brake caliper 4; the first brake caliper 3 includes a first brake pad 3.1 and a first brake piston 3.2, a second brake piston 3.3, and the second brake caliper 4 includes a second brake pad 4.1 and a third brake pad 4.1 The movable piston 4.2, the fourth brake piston 4.3. The diameter of the brake disc 2 selected in this embodiment is 280mm, the outer radius of the brake disc 2 is 130mm, the inner radius is 110mm, the friction coefficient of the two brake pads is about 0.4, and the effective area A of the four brake pistons is about is 2×10 -3 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com