Driving-force transmission mechanism and image forming apparatus equipped therewith

A technology of power transmission device and pressure, applied in the direction of friction transmission device, transmission device, transmission device parts, etc., can solve the problems of increased product cost, complicated assembly operation and high material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

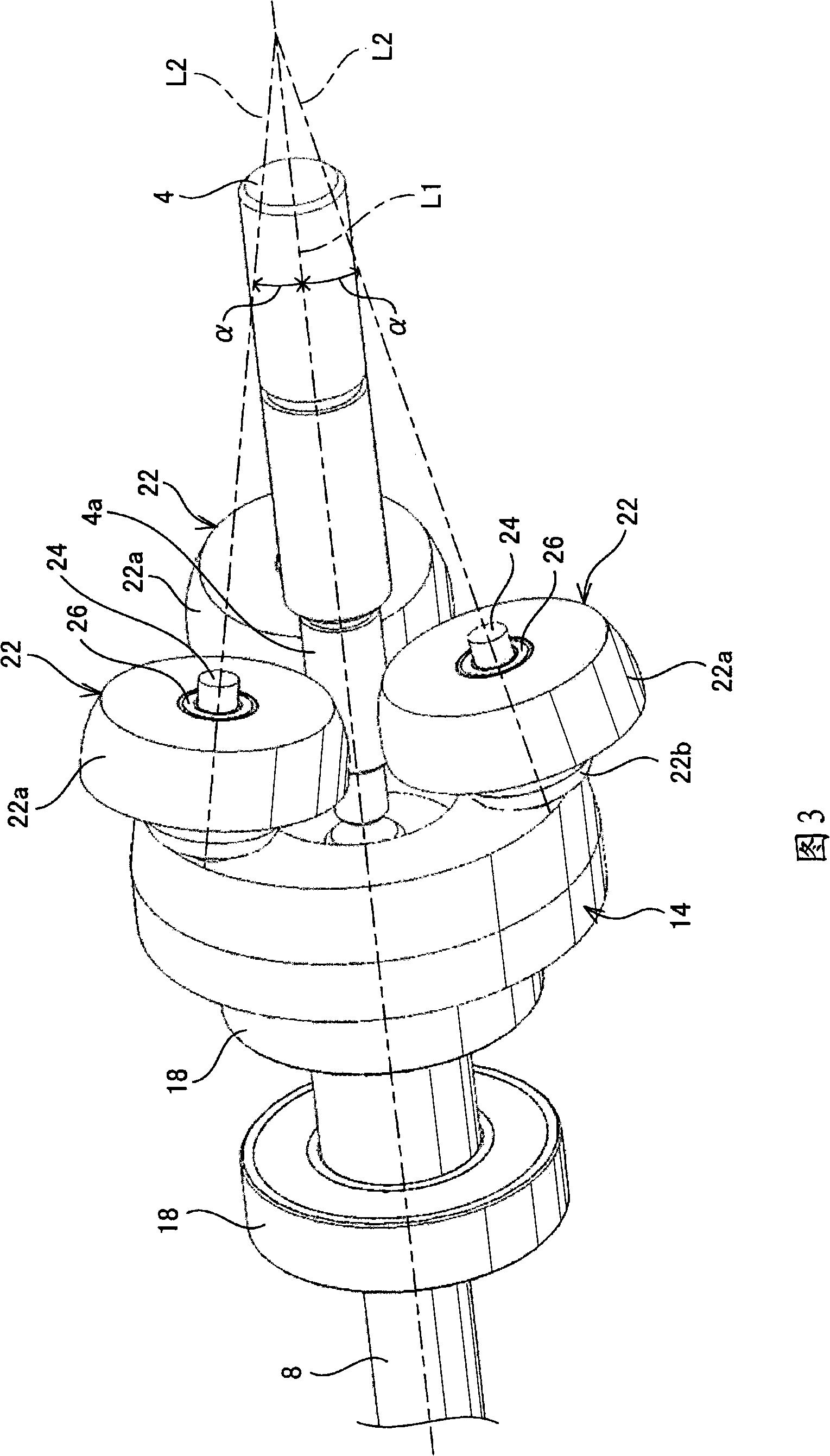

[0068] The second modified embodiment shown below is a preferred mode in which the outer ring 10 presses the planetary rollers 22 .

[0069] Figure 11 It is an enlarged view showing a portion where the planetary rollers 22 are pressed by the outer ring 10 . As described above, by pressing the pressing surface 10b of the outer ring 10 against the pressure receiving surface 22b of the planetary roller 22 with a large force, the planetary roller 22 is slightly moved along the shaft member 24 (peripheral axis L2). At this time, the planetary rollers 22 press the sun roller 4 with a large force in the radial direction according to the inclination of the peripheral axis L2 with respect to the rotational axis L1 of the sun roller 4 . In the presence of grease, a frictional force is generated between the peripheral surface 22a of the planetary roller 22 and the peripheral surface 4a of the sun roller 4 by this pressing force.

[0070] At this time, if Figure 11 As indicated by ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com