Operating mechanism of electrical protection apparatus

A technology of electrical protection device and operating mechanism, which is applied in the direction of protection switch operation/release mechanism, etc. It can solve the problems that the operating mechanism cannot move quickly, the space occupied by the operating mechanism is large, and the time consumed by linkage reaction is long, etc., and the operating mechanism is compact , Simple structure, easy to use and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

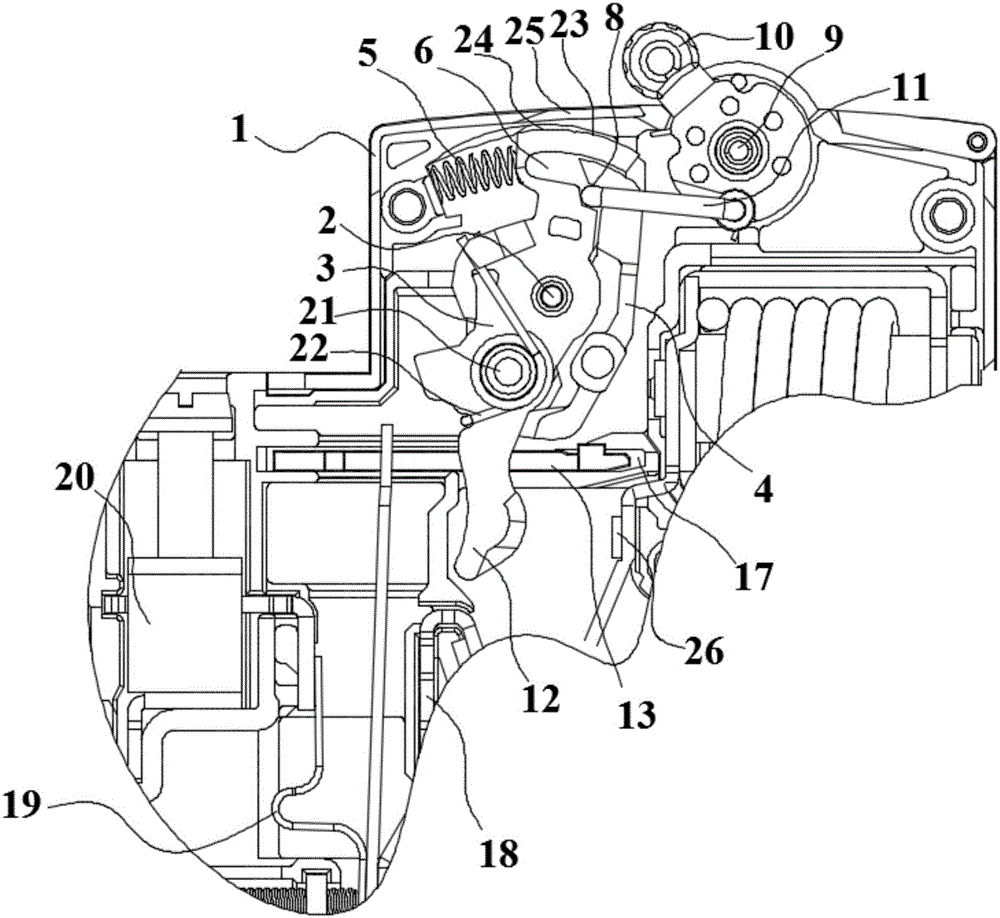

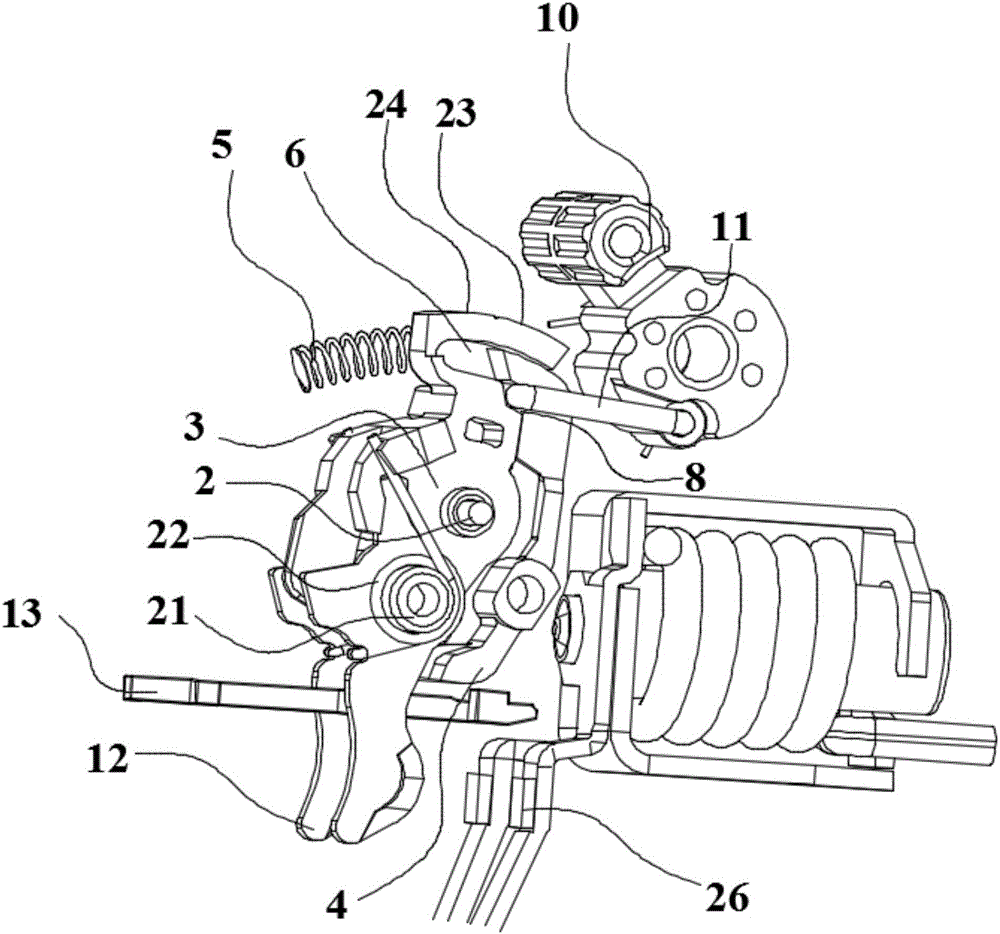

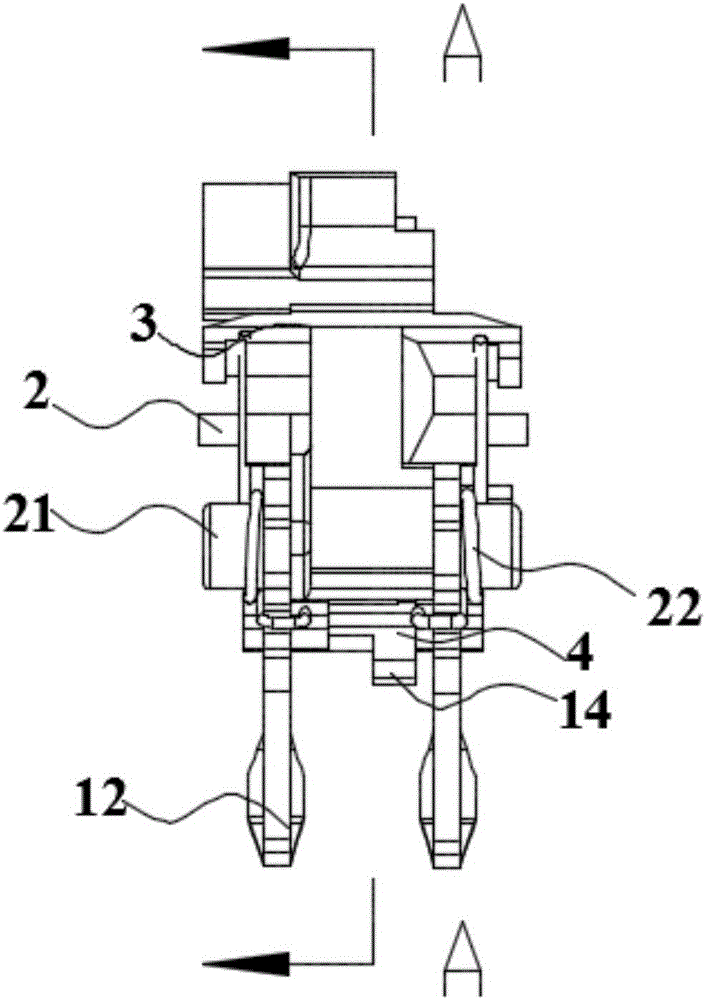

[0030] The operating mechanism of the electrical protection device in the present invention, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a housing 1, a handle 10 is arranged in the housing 1 through the rotation of the handle shaft 9, a bracket 3 and a lock 4 are arranged in the housing 1 through the coaxial rotation of the bracket shaft 2, and the middle part of the lock 4 is provided with a convex The platform 41 and the lock catch 4 are rotated on the support shaft 2 through the boss hole 42 provided on the boss 41. The support 3 is provided with a middle recess 27, and the boss 41 is located in the middle recess 27. The support shaft 2 is provided with There is an axial torsion spring 7, one end of the axial torsion spring 7 is fixed on the inner wall of the middle recess 27, the other end of the axial tors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com