Automatic inspection device for raw silk cohesion and method for inspecting raw silk cohesion

An automatic inspection and cohesion technology, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of large impact force of raw silk under test, low degree of automation, and large difference in results, so as to improve efficiency and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

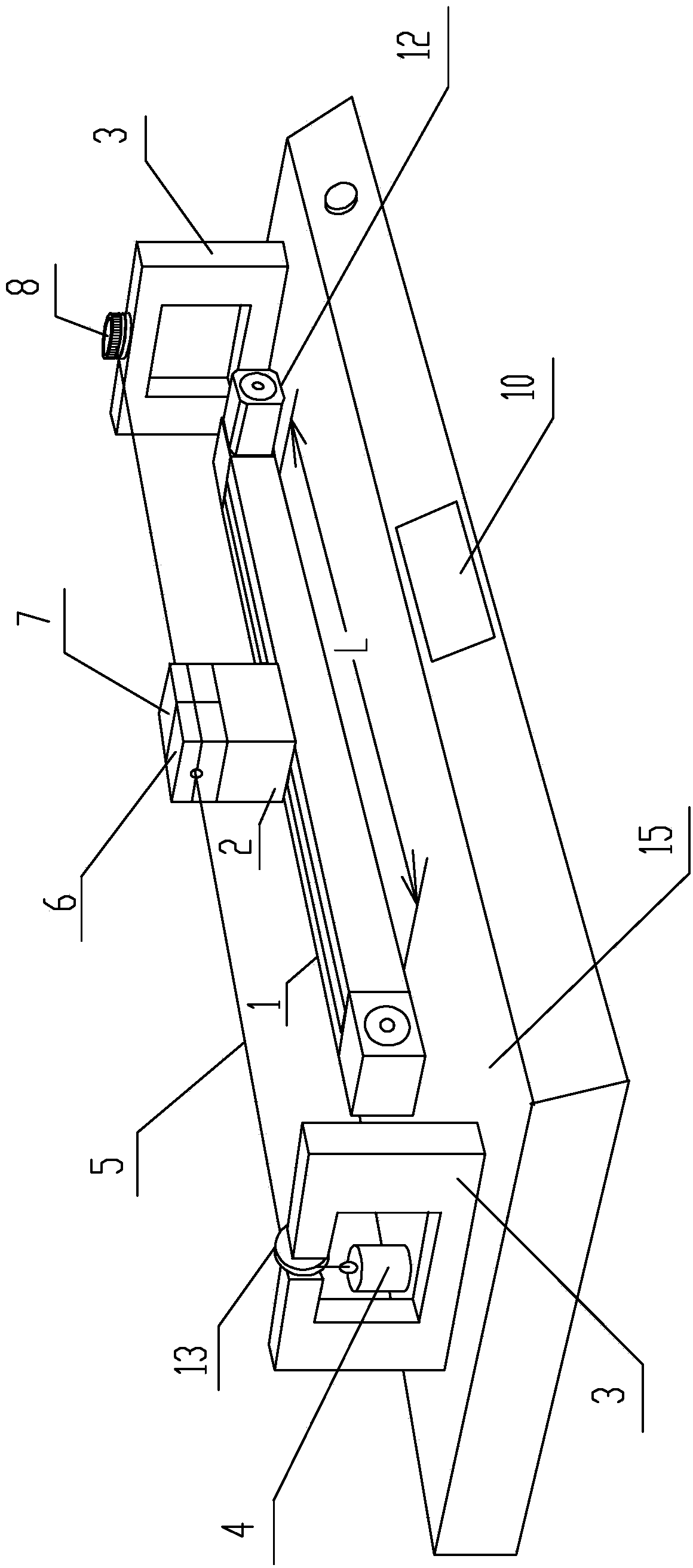

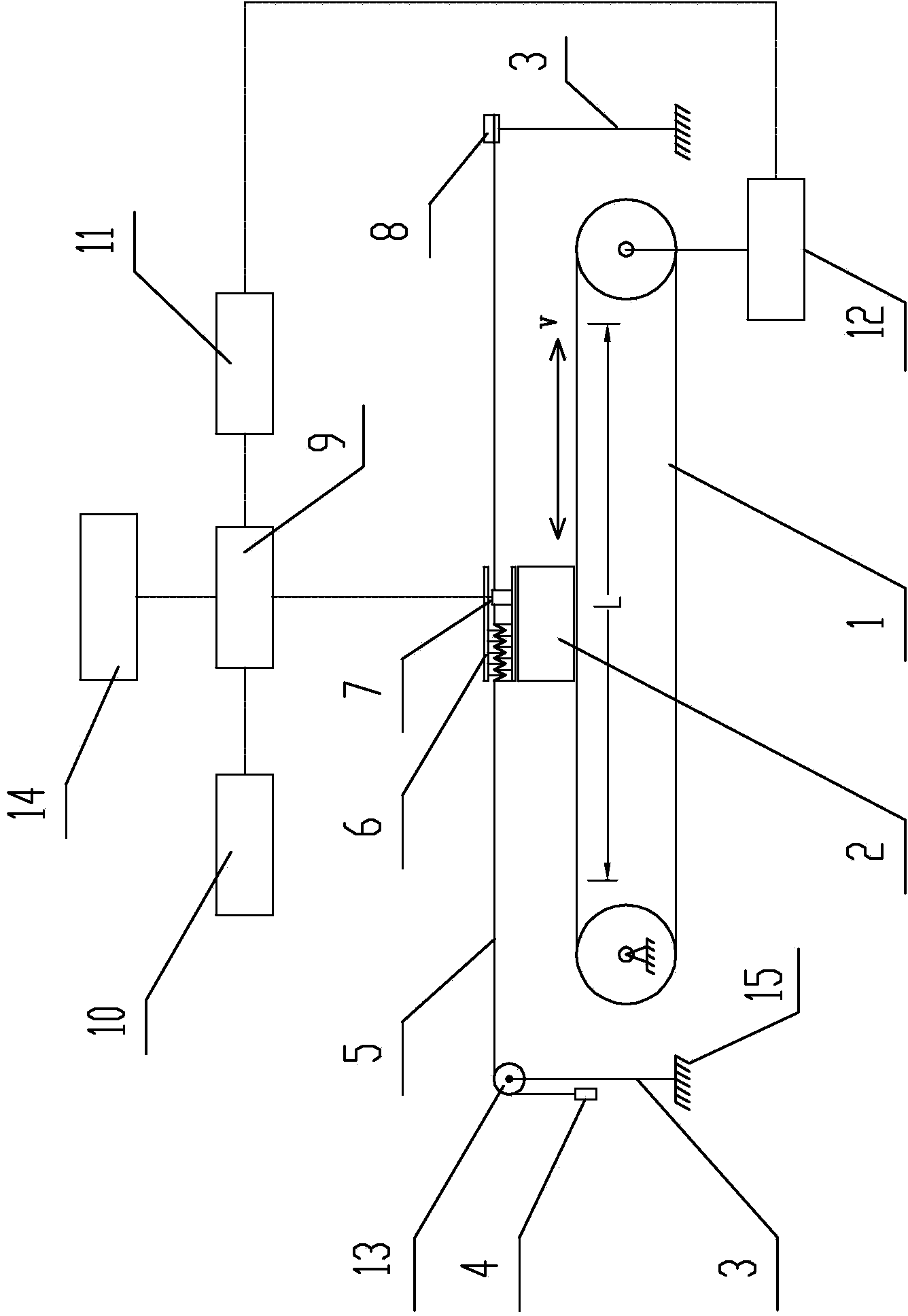

[0039] An automatic testing device for cohesion of raw silk, such as figure 1 , figure 2 As shown, the raw silk cohesion automatic inspection device includes a reciprocating linear slide table 1, a reciprocating slider 2, two raw silk support frames 3, a raw silk tension weight 4, a friction blade set 6, a capacitive silk density sensor 7, and a wire clip nut 8. Programmable controller 9, touch screen 10, motor driver 11, slide motor 12, guide wire pulley 13, computer 14 and base 15, see the connection relationship and principle figure 2 ;

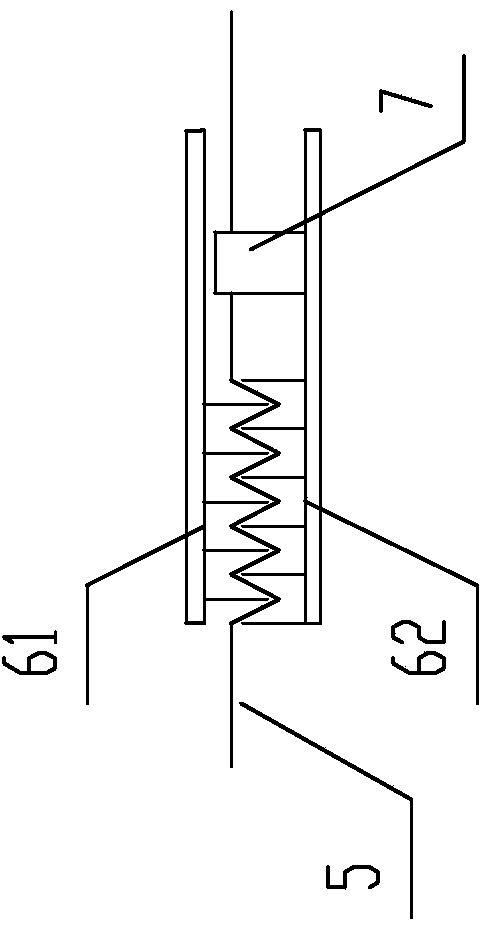

[0040] The reciprocating linear slide 1 is installed on the base 15, and there is a raw silk support frame 3 for installing the raw silk strip 5 to be tested on each side, and the reciprocating slide 2 is installed on the linear slide 1, and a friction blade group is fixedly installed on it. 6 and a capacitive wire density sensor 7, the slide motor 12 for driving the reciprocating slider 2 is installed at one end of the linear slide 1;...

Embodiment 2

[0048] A method for detecting the cohesion of raw silk, which is a method for detecting the cohesion of raw silk by using the automatic inspection device for cohesion of raw silk described in Embodiment 1, that is, using a linear reciprocating linear slide to drive the friction blade group on the reciprocating slider to Constant and uniform speed reciprocating friction on the detected raw silk sliver at a constant linear speed; at the same time, through the follow-up capacitive silk density detection sensor to detect the splitting of the detected raw silk sliver due to friction; when the detected raw silk sliver When the generated splitting condition reaches the set value, the cohesion performance of the raw silk is determined by a programmable controller or a computer. The effective stroke L of the slider 2 is determined; the number n of the capacitive silk density sensor 7 is the same as the number of the measured raw silk sliver 5, that is, a measured raw silk sliver is equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com