Three-roller machine

A technology of three-roll machine and rear roller, which is applied in the field of machinery, can solve the problems of uneven roller shaft surface, high grinding amount, and affecting the grinding effect, so as to achieve uniform force and friction, prevent accidental damage, and have a long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

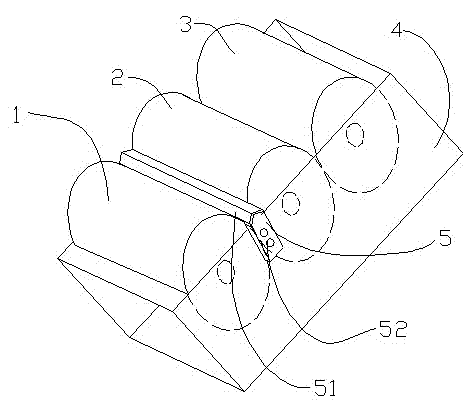

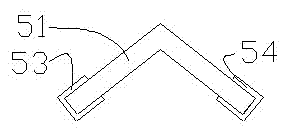

[0022] exist figure 1 In the shown embodiment, the three-roll machine comprises a rear roll 1, a middle roll 2, a front roll 3, a frame 4, and a stopper device 5, and the stopper device 5 includes a stop bar 51, a connecting assembly 52, and the stop bar 51 is a straight strip with an inverted V-shaped cross section, located directly above the approach line of the rear roller 1 and the middle roller 2, and parallel to the respective axes of the three rollers. On the outer cylindrical surface of the roller 1 and the middle roller 2 , the connecting assembly 52 is connected to both ends of the bar 51 to fix the bar 51 on the frame 4 .

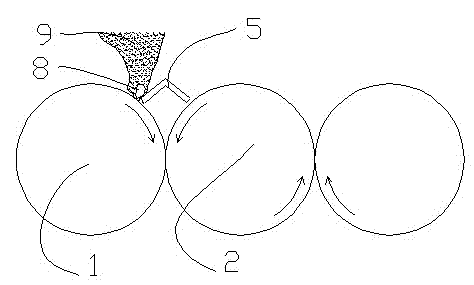

[0023] Such as figure 2 As shown, the blocking device 5 is installed above the rear roller 1 and the middle roller 2, parallel to and close to the outer cylindrical surface of the rear roller 1 and the middle roller 2, and the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com