Vibration auxiliary abrasive particle flowing electrolysis micro grinding composite finishing process method

A technology for auxiliary abrasive grains and processing methods, applied in the field of electrolytic processing, can solve problems such as low efficiency, reduced reliability, and high labor intensity, and achieve broad development prospects, enhanced uniformity, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

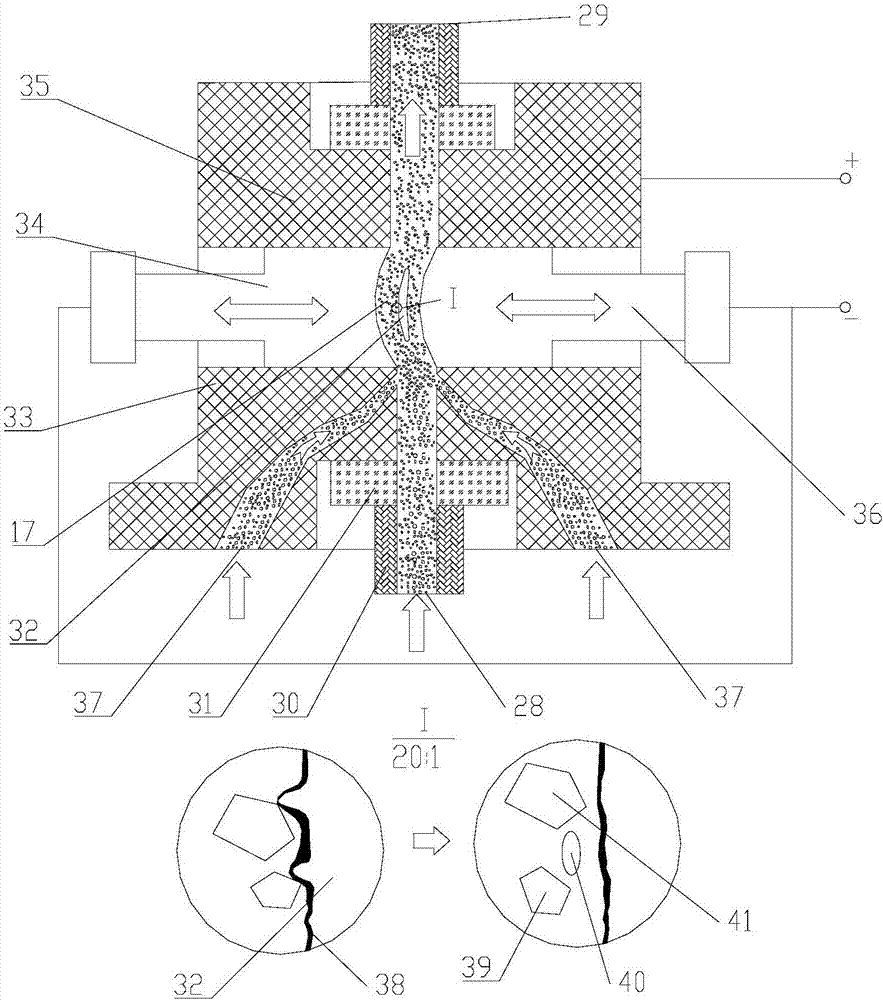

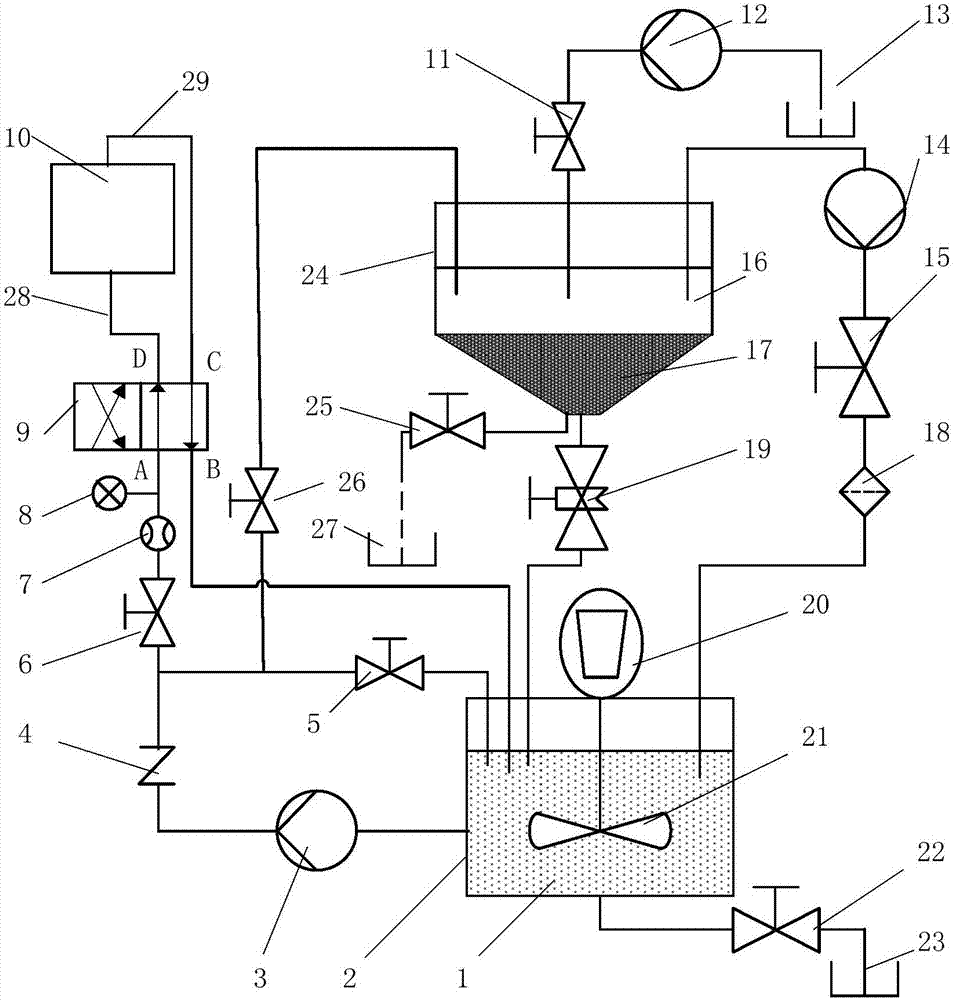

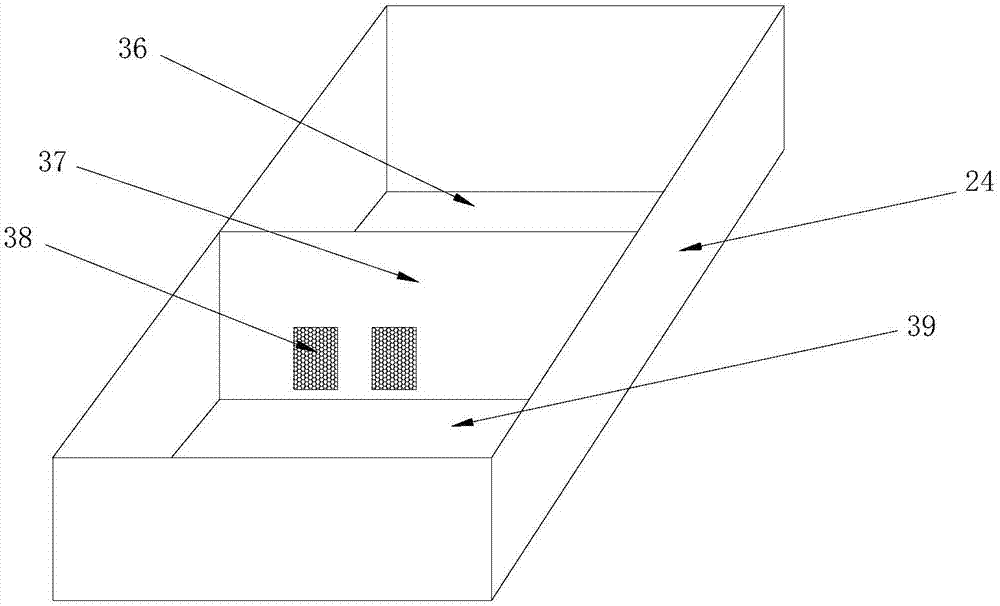

[0020] The following is an example of vibration-assisted abrasive flow micro-grinding and electrolytic composite finishing. figure 1 , attached figure 2 And attached image 3 The implementation process of vibration-assisted abrasive flow micro-grinding electrolytic composite finishing device and method is described:

[0021] Vibration-assisted abrasive flow micro-grinding electrolytic composite finishing device, including: fixture part, abrasive flow circulation system, and reversing feeding system;

[0022] The fixture part is assembled by tooling upper clamping body 33, lower clamping body 35, tool leaf back cathode 34, tool leaf basin cathode 36, workpiece anode blade 32, sealing device 31, and flow guiding device 30; tool leaf back cathode 34, tool The leaf pot cathode 36 is connected to the spindle of the six-axis linkage vibration electrolysis machine tool, and the workpiece anode blade 32 is positioned and clamped by the conductive plate, so that the tool blade back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com